How Detachable Cable Car(Ropeway) Works - Adventure You Won't Forget

Summary

TLDRThis video explains the working of ropeways, commonly used in hilly regions where road construction is challenging. It covers the two types of ropeways—detachable and non-detachable—and the mechanics behind them, including motor types, gear systems, brakes, and safety features. It also details the process of detaching and reattaching gondolas, emergency braking systems, and how the cable is continuously monitored for safety. The video highlights the importance of safety measures in ropeway systems, the role of 3D animation in understanding these technologies, and the continuous monitoring of all equipment to prevent failures.

Takeaways

- 😀 Ropeways are mainly used in hilly areas where building roads is challenging.

- 😀 There are two main types of ropeways: detachable and non-detachable.

- 😀 Detachable ropeways allow gondolas to detach from the cable at the station for easier loading and unloading of passengers.

- 😀 A high-torque motor at the ground station powers the entire ropeway system.

- 😀 Power from the motor is transmitted through a gear system to the sheave, which moves the rope and the gondolas.

- 😀 Gondola speed can vary, ranging from an average of 3-5 m/s to up to 14 m/s in some cases.

- 😀 A coil spring mechanism is used to detach the gondola from the cable smoothly when it reaches the station.

- 😀 Tires around the station help move the gondola forward after it detaches from the cable.

- 😀 Safety features include proximity sensors, rope deflectors, rope catchers, and emergency braking systems.

- 😀 In the event of power failure, a backup hydraulic motor system ensures that the gondolas can be safely stopped or moved.

- 😀 Continuous optical monitoring is used to check the cable for any potential issues, such as broken wires or scratches.

Q & A

What are the two main types of ropeways?

-The two main types of ropeways are detachable and non-detachable ropeways. Detachable ropeways allow the gondolas to detach from the main cable at the station, while non-detachable ropeways keep the gondolas attached to the cable throughout the journey.

How do detachable ropeways work?

-In detachable ropeways, the gondolas detach from the cable as they reach the station. The speed of the gondola is reduced, allowing passengers to board or exit. The gondola then moves on small tires, powered by a motor, to proceed forward or backward at the station.

What type of motor is commonly used in ropeways?

-Ropeways typically use high-torque motors such as slip ring induction motors, DC series motors, or synchronous motors. These motors provide the necessary power to move the rope and gondolas and are often cooled by a blower mounted on top.

What role do gear systems play in ropeway operations?

-Gear systems, including a two-stage planetary gear and bevel gear, are used to increase the torque produced by the motor. This helps transfer power efficiently to the sheaves that move the rope, ensuring that the gondolas can travel at the required speed.

How are gondolas detached from the cable in a detachable ropeway?

-Gondolas are detached using a parlley coil spring system. When the gondola reaches the station, a wheel presses against the spring, which releases the grip on the cable. This allows the gondola to move off the cable and rest on small wheels.

How do safety features prevent accidents in ropeways?

-Ropeways have multiple safety features, including rope catchers, proximity sensors to monitor cable position, emergency brakes activated by a red cable, and optical testing systems that detect damage to the cable. These systems ensure that the gondolas remain safe during operation.

What happens if the cable gets off the tower or misaligns?

-If the cable gets off the tower or misaligns, proximity sensors on the rollers detect the issue and immediately send a signal to the control system, which applies the brakes to stop the movement of the ropeway, preventing any further damage or danger.

How does a ropeway system handle power failure?

-In the event of a power failure, a backup hydraulic motor can be activated to ensure the gondolas don't get stuck. Additionally, the system includes a centrifugal switch that applies a hydraulic brake to stop the sheave if the speed exceeds normal limits.

Why are small tires used in detachable ropeways?

-Small tires are used to support the gondola after it detaches from the cable. These tires allow the gondola to move smoothly along the station platform, where it is slowed down and then reattached to the cable at the right speed.

What is the role of solar panels in ropeway gondolas?

-Solar panels are often installed on ropeway gondolas to provide a power source for basic lighting and other small electrical needs. This helps reduce the reliance on external power sources and enhances energy efficiency.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

How alternating current motors work?

20 November 2024

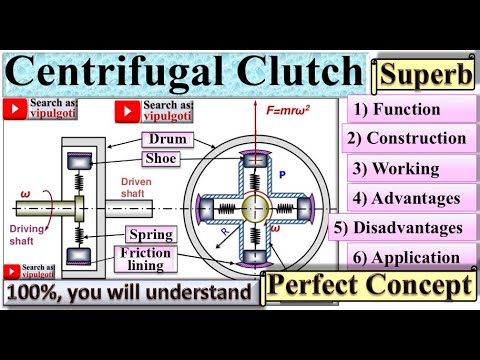

Centrifugal clutch, #Clutch, Function and working of Clutch, #Centrifugal #GTU #BME

Structural Theory 1 Chapter 1 Part II (with Subtitles)

Unicasts, Broadcasts, and Multicasts - CompTIA Network+ N10-007 - 1.3

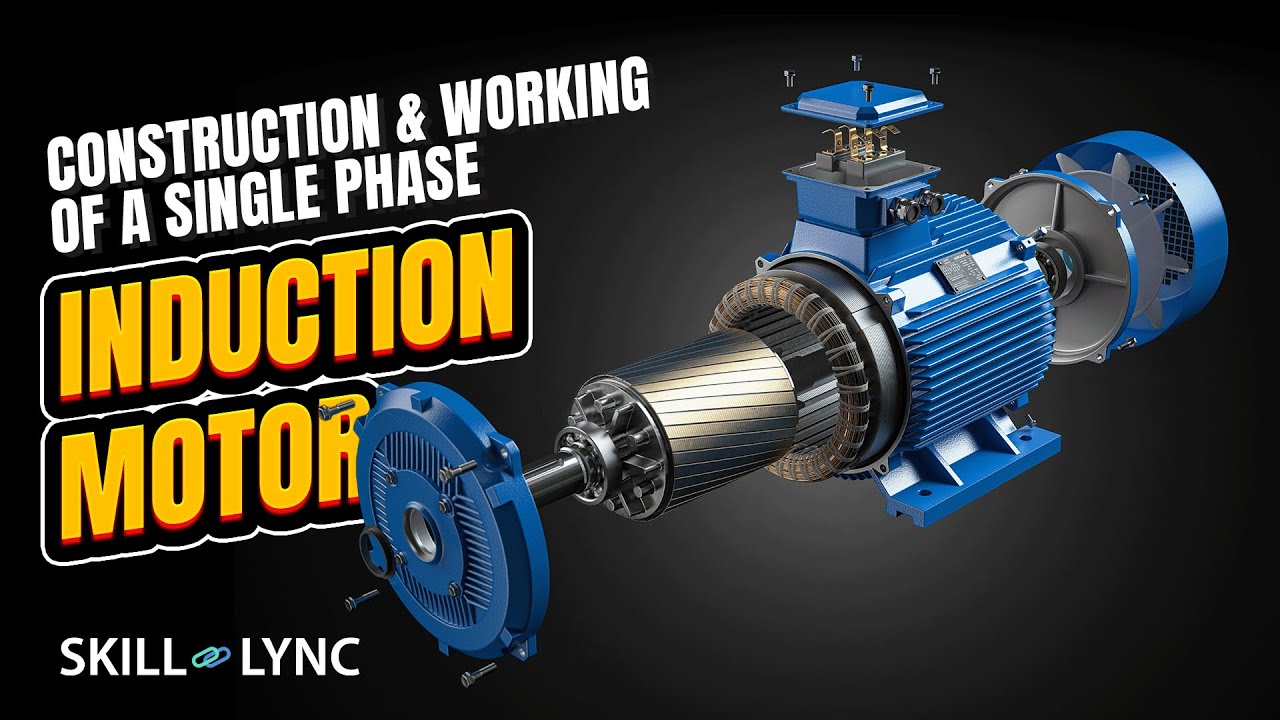

Construction and Working of a Single phase Induction Motor | Skill-Lync

5.0 / 5 (0 votes)