Murah meriah!!!Cara laminasi dingin cover buku

Summary

TLDRThis tutorial teaches you how to laminate book covers using a budget-friendly, DIY approach. The process involves setting up a simple laminating machine, adjusting the temperature, and feeding the cover through the laminator. The video provides step-by-step instructions, tips for saving money by modifying equipment, and the benefits of doff laminating. It’s perfect for DIY enthusiasts, small business owners, or anyone looking to create professional-looking laminated book covers without the high costs of commercial services.

Takeaways

- 😀 Laminating a book cover with a doff finish gives it a matte, darker look that reduces glare and makes it easier on the eyes.

- 😀 You need a laminating machine, plastic roll, and the book cover to start the lamination process.

- 😀 A simple, affordable laminating machine like Vitex (around IDR 300,000) can be used for this process.

- 😀 A customized stand for the plastic roll can be made to save costs, making the lamination process more efficient.

- 😀 Set the laminating machine temperature to around 120-130°C for a safe and effective lamination.

- 😀 The machine has two main modes: hot lamination for regular use and cold lamination for more delicate materials.

- 😀 The laminating machine will automatically pull the plastic and cover through, ensuring even lamination.

- 😀 Patience is required during the lamination process, as it may take time for each cover to fully pass through the machine.

- 😀 After laminating, trim any excess plastic to achieve a clean and professional finish.

- 😀 This DIY laminating method is cost-effective and ideal for small businesses or individuals who need to laminate multiple covers.

- 😀 The result is a durable, attractive cover that is less prone to wear and tear, ideal for books or printed images.

Q & A

What is the main purpose of laminating a book cover with a 'dof' finish?

-The 'dof' finish provides a matte coating that darkens the cover slightly and makes it more visually comfortable, reducing eye strain and offering a pleasant viewing experience.

What equipment and materials are required for laminating book covers?

-You will need a book cover, laminating plastic with a 'dof' finish, a laminating machine (such as the Vitex brand), and a stand for the plastic roll, which can be DIY-modified for cost-efficiency.

How does the 'dof' finish affect the appearance of the book cover?

-The 'dof' finish darkens the cover slightly, making it appear matte, which reduces glare and makes it easier on the eyes during prolonged viewing.

Why is it recommended to set the laminating machine temperature to around 130°C?

-Setting the laminating machine to 130°C ensures that the plastic is heated enough to adhere to the book cover without being too hot, which could potentially damage the cover or the plastic.

What is the purpose of the hot and cold settings on the laminating machine?

-The hot setting is used for laminating (when the plastic needs to fuse to the book cover), while the cold setting is used for reversing or adjusting the process, often used in cases where the laminating process needs to be undone.

How can the laminating machine be modified to save on costs?

-A DIY modification can be done by creating a stand for the plastic roll, which is cheaper than buying a pre-made one. The speaker uses an affordable Vitex laminating machine and a simple modification to hold the roll.

What should you do after the laminating process is complete?

-After laminating, trim any excess plastic around the book cover to give it a clean and finished look.

How do you know when the laminating machine is ready for use?

-The laminating machine is ready when the indicator light turns green, signaling that it has heated up to the appropriate temperature.

What are the advantages of using a DIY laminating setup as mentioned in the script?

-A DIY laminating setup is more cost-effective compared to purchasing expensive pre-made machines. By modifying a cheaper machine and creating your own stand, you can significantly reduce costs while achieving the same results.

Why is patience important during the laminating process?

-Patience is crucial because the laminating process takes time to ensure that the plastic adheres properly and the book cover is laminated smoothly, especially when processing multiple covers.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

How to Create an eBook with AI and Sell it Online (Make $500/Week)

DIY BUKET SNACK LOWBUDGET || BUKET SNACK ANTI LETOY || BUKET SNACK TANPA LEM TEMBAK

Cara membuat alat penyaring udara sederhana

Budget Subwoofer Build (The Budget Bass Box)

Cara mudah merakit Power Bank dengan Panel Surya | Power Bank 26.000 Mah

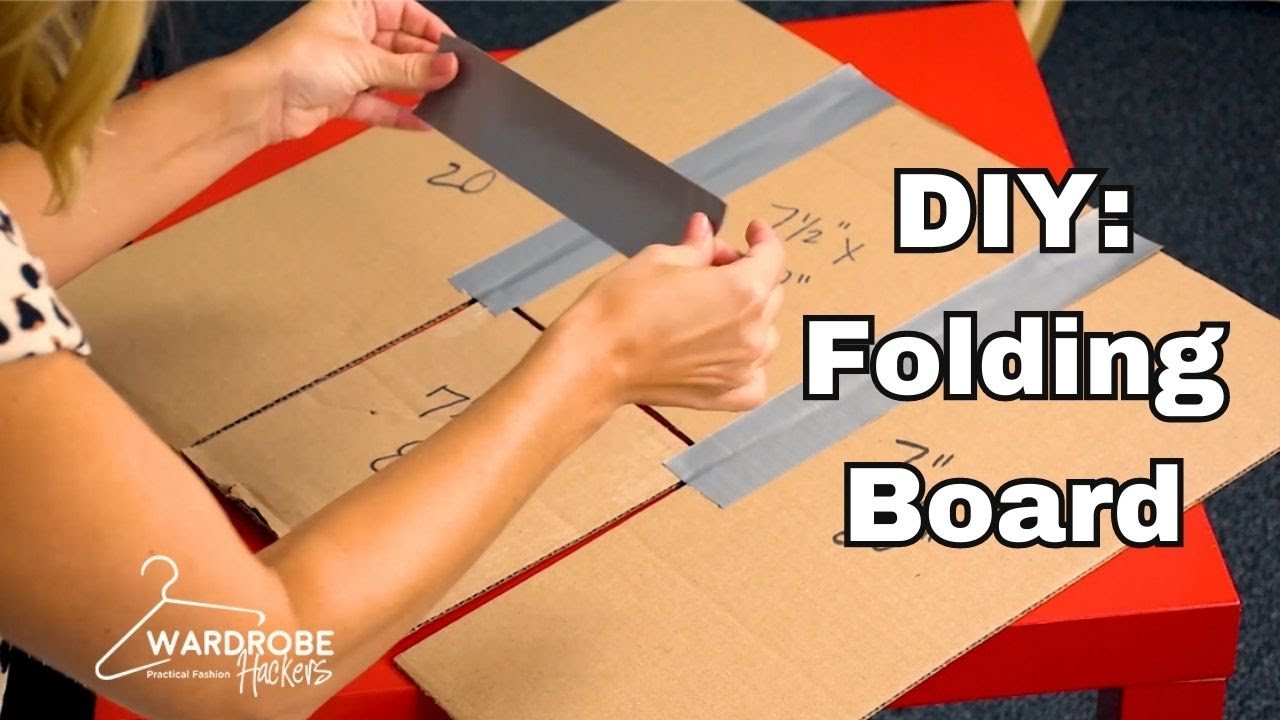

How to Make a DIY Kids Shirt Folding Board for Super Cheap

5.0 / 5 (0 votes)