Inside the world's first humanoid factory, where robots could eventually build themselves

Summary

TLDRAgility Robotics' RoboFab is the world’s first factory for humanoid robots, producing the robot Digit for clients like Amazon. The company’s CEO, Peggy Johnson, explains how their 70,000-square-foot facility aims to meet the growing labor gap, especially in logistics, by introducing robots like Digit. The robot is designed to assist with physically demanding tasks and is integrated with AI for efficiency. While Agility Robotics is still scaling up, their 'Robots as a Service' model offers flexibility to customers. As technology advances, humanoid robots could soon become commonplace in various industries.

Takeaways

- 😀 Agility Robotics, founded in 2015 as a spin-off from Oregon State University, has built the world's first humanoid robot factory, RoboFab.

- 😀 The RoboFab facility, spanning 70,000 square feet, is designed to produce up to 10,000 units of Digit, a humanoid robot, annually.

- 😀 Digit is aimed at addressing the large labor gap, particularly in logistics, by performing tasks that are typically unappealing to humans.

- 😀 The current version of Digit weighs 160 pounds and can lift up to 30 pounds, adhering to US Occupational Safety and Health Administration guidelines.

- 😀 Digit's battery life is set to improve with the next generation, moving from a 2:1 charge-to-use ratio to a 4:1 ratio.

- 😀 Version 5 of Digit, already in development, will feature more advanced AI integration and the ability for the robot to recharge itself.

- 😀 Agility Robotics is collaborating with AI companies like Nvidia to build foundational models for humanoid robots.

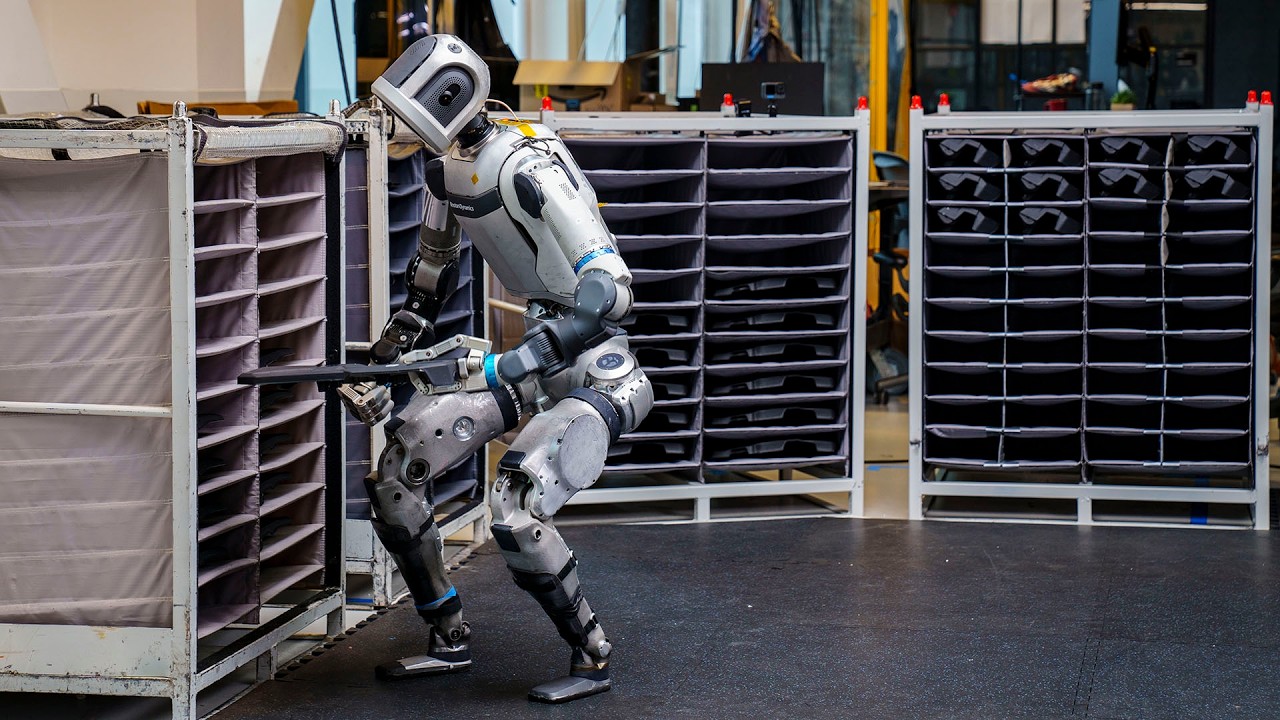

- 😀 Digit is equipped with interchangeable grippers and unique legs that allow it to navigate tight spaces, such as close to shelves.

- 😀 Data from Digit's operations is uploaded to Agility's cloud platform, ARC, which helps train the robot and continuously improve its capabilities.

- 😀 Agility Robotics offers two pricing models for Digit: a capital expenditure (CapEx) model and a 'Robots as a Service' subscription model, which includes software, maintenance, and support.

- 😀 Despite being unprofitable so far, Agility has raised $190 million in capital and plans to scale operations, which could eventually lead to cost savings and profitability.

Q & A

What is the primary purpose of Agility Robotics' RoboFab facility?

-RoboFab is Agility Robotics' manufacturing facility, where they produce their humanoid robot, Digit. It is the world's first factory dedicated to humanoid robots, with a production capacity of 10,000 units per year.

When was Agility Robotics founded, and what is its connection to Oregon State University?

-Agility Robotics was founded in 2015 as a spin-off company from Oregon State University. It focuses on the development and manufacturing of humanoid robots.

How does Agility Robotics address the labor gap with their humanoid robots?

-Agility Robotics addresses the labor gap, particularly in logistics, where over a million jobs remain unfilled. Robots like Digit can take over specific tasks, freeing up humans to focus on more complex tasks and learning new skills.

What is the weight and height of the current version of Digit?

-The current version of Digit weighs 160 pounds (72 kg) and stands at 5-foot-9 inches (175 cm).

What is the current battery life of Digit, and how is it expected to improve?

-In the existing generation, Digit has a two-to-one charge ratio, meaning it charges for one hour and operates for two hours. The next generation aims to improve this to a four-to-one ratio.

What features will be incorporated in Digit’s Version 5?

-Version 5 of Digit will include collaborative safety, allowing humanoid robots to work alongside humans safely, along with enhanced AI integration and the ability for Digit to recharge itself using a charging stand.

How does Digit's software help in its operation?

-Digit’s software provides real-time monitoring and tracking of tasks. For instance, it can identify objects, track their movement, and plan its actions accordingly. The robot’s hands are equipped with different grippers, and its legs are designed for efficient movement in tight spaces like shelves.

What is ARC, and how does it support Digit's development?

-ARC is Agility Robotics’ cloud platform that collects and processes telemetry data from Digit. This data is crucial for training the robot to perform tasks, improving its functionality, and making it adaptable to various customer needs.

What is the business model for acquiring Digit, and what does it include?

-Agility Robotics offers two models: the CapEx (Capital Expenditure) model, where customers purchase the robot outright, and the popular 'Robots as a Service' model, where customers pay a monthly fee that includes software, maintenance, and support.

How much does Digit cost, and how does it compare to other high-end products?

-The cost of Digit is comparable to that of a luxury car, though the exact price is not disclosed. Agility Robotics has raised significant capital to fund development and is focusing on scaling operations for cost savings in the future.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Pick, Carry, Place, Repeat | Inside the Lab with Atlas

Shocking AI Robots That Could Replace Us Unveiled at the 2024 World Robot Conference

New AI Humanoid ROBOTS That Will Soon OUTPERFORM HUMANS

The Insane Tech You Missed From CES 2025 | MOONSHOTS

Shocking Inventions Unveiled at Future Technology Exhibitions at WRC 2024 | Pro robots

How Realistic Are Today’s Robots?

5.0 / 5 (0 votes)