Business Case: Multi-Warehouse Inventory Management

Summary

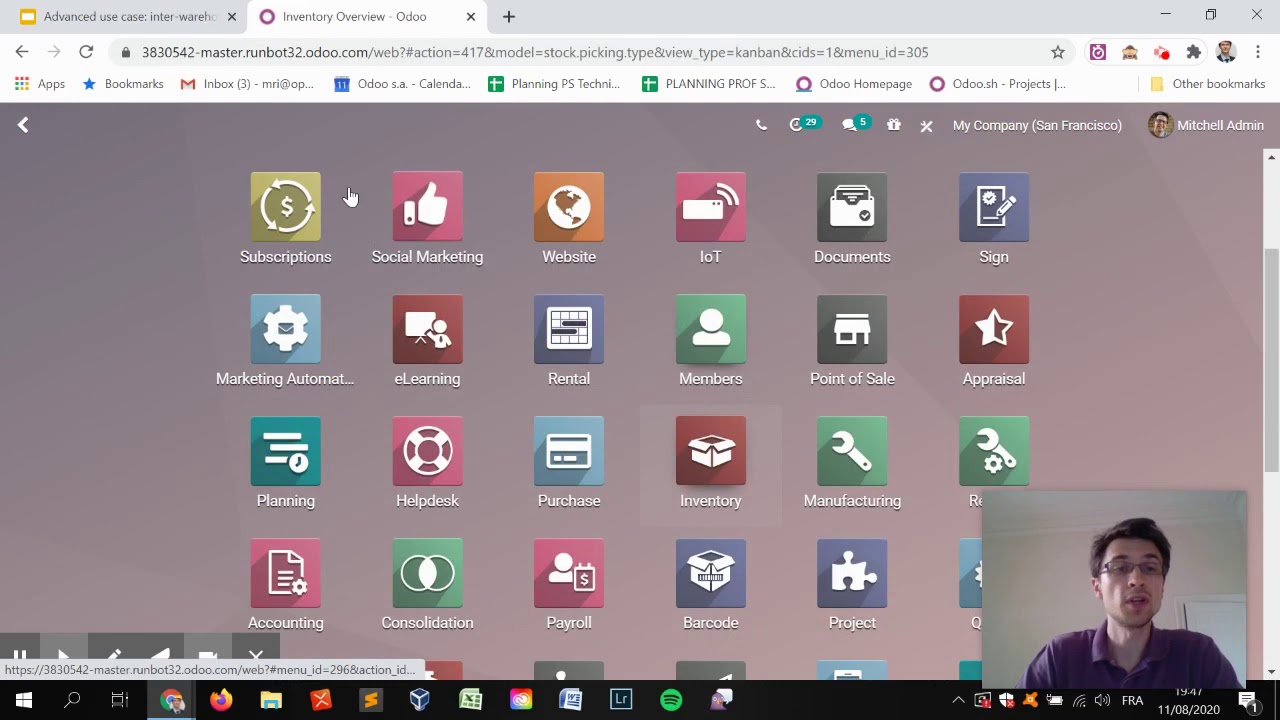

TLDRIn this video, Michael, a supply chain expert, presents a use case from Superstars, a retail chain in the DIY industry, facing challenges with manual ordering processes between their stores and central warehouse. The company seeks to automate its resupply logistics, freeing up time for staff and improving efficiency. The video explores how Superstars can optimize its supply chain, discussing the current setup, key pain points, and potential solutions using ADO software. The focus is on creating an automated, streamlined process for purchasing, resupply, and store-to-store transfers, with the aim of reducing manual tasks and improving operational efficiency.

Takeaways

- 😀 Superstars is a retail chain in the DIY industry, focused on providing products at the lowest possible cost.

- 😀 The company operates with one central warehouse (distribution center) and four remote stores that rely on the central warehouse for resupply.

- 😀 Stores are not allowed to order products directly from external suppliers; they only restock from the central warehouse.

- 😀 The purchasing department in the central warehouse places large orders to external suppliers to stock up both the central warehouse and stores, especially at product launches.

- 😀 A long-term goal is to maintain minimum stock levels in stores and the central warehouse, and automate the resupply process to improve efficiency.

- 😀 A key challenge is that store staff currently spends too much time manually placing orders with the distribution center.

- 😀 Superstars aims to automate the ordering process so store employees can focus more on their day-to-day tasks rather than restocking inventory.

- 😀 The resupply strategy involves automated stock replenishment from the central warehouse to stores and occasional internal resupply between stores.

- 😀 The main questions addressed in the use case involve the preferred network setup and how to manage occasional resupply from store to store.

- 😀 The solution will likely be implemented using ADO software, which will help configure the network and automate supply chain processes for better efficiency.

Q & A

What is the main objective of Superstars in this supply chain setup?

-Superstars aims to streamline and automate its supply chain process, reducing manual effort in ordering and dispatching products, while maintaining cost efficiency and stock levels across stores and the central warehouse.

How is the supply chain network structured at Superstars?

-Superstars has one central warehouse (distribution center) and four remote stores that rely on the central warehouse for product orders. The warehouse handles purchasing and dispatches products to stores based on a predetermined repartition key.

What is the purchasing strategy used by Superstars?

-Superstars centralizes its purchasing activity at the central warehouse to leverage bulk purchasing power, ensuring that the stores are stocked with forecasted amounts of goods. Large orders are placed with external suppliers to fill the warehouse and supply stores during product launches.

What is the current pain point Superstars is facing in its supply chain?

-Superstars' main pain point is the excessive manual effort spent by store employees on ordering products from the central warehouse. This process detracts from their focus on other day-to-day activities.

What is the long-term supply chain strategy for Superstars?

-The long-term strategy is to automate the replenishment process for stock resupply between the stores and the central warehouse, and between the central warehouse and external suppliers. This aims to reduce manual labor and improve operational efficiency.

What is the role of the distribution center in Superstars' supply chain?

-The distribution center serves as the primary hub for purchasing products, receiving stock from external suppliers, and dispatching it to stores. It ensures that stores are stocked with the right quantities, based on a repartition key, and manages overall stock levels.

Why is Superstars seeking to automate the resupply process?

-Superstars seeks to automate the resupply process to minimize manual ordering tasks performed by store employees, allowing them to focus on other important tasks. Automation would also improve inventory accuracy and overall operational efficiency.

What is the intended benefit of using ADO software in this context?

-ADO software is intended to automate the ordering and resupply processes, helping to streamline operations and reduce manual effort. It could also offer advanced features to optimize stock management, improve inventory forecasting, and enhance communication between the central warehouse and stores.

How are the stores stocked with products initially after a new product launch?

-When a new product range is launched, the purchasing department places a large order to external suppliers to fill the distribution center with buffer stock and provide the stores with an initial forecasted amount of stock.

What is the importance of the repartition key in Superstars' supply chain?

-The repartition key is crucial for ensuring that products are distributed from the central warehouse to the stores in an efficient and predetermined manner. It helps maintain stock levels that align with the stores' needs and ensures that resources are allocated effectively.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

American Eagle Outfitters' Supply Chain Innovation Award Competition Case Study

The history & evolution of retail industry

Multi-Warehouse Management: Solution (part 2)

What is Warehouse Management? [Intro to Inventory Management, Pick Pack Ship, WMS Software, etc]

Entrevista com José Gracio, especialista em Supply Chain

How FEDEX delivery supply chain strategy works | Logistics | MBA Case study analysis with Solution

5.0 / 5 (0 votes)