toleransi pada pemesinan kelas XI

Summary

TLDRThis video explains the concept of tolerance in mechanical engineering, focusing on its importance in ensuring proper fit between paired parts like shafts and holes. It covers key terms such as nominal size, tolerance limits, maximum and minimum deviations, and the differences between clearance and interference fits. The speaker also discusses practical examples like machining a shaft to a precise diameter, and how different tolerances are critical in ensuring functional and technical requirements are met, avoiding product failures, and achieving the desired fit in various applications like bearings and motor wheels.

Takeaways

- 😀 Tolerance refers to the permissible limits of variation in the dimensions of a manufactured part, ensuring proper fit despite minor discrepancies.

- 😀 Tolerances are essential in manufacturing to account for variations in size, ensuring parts still function properly even if they don't match the nominal size exactly.

- 😀 A shaft, for example, may initially be larger than the required size, and machining (e.g., turning on a lathe) reduces it to the intended size, but tolerance defines the acceptable range of this reduction.

- 😀 The concept of 'tolerance' also includes upper and lower limits; if a part's actual size falls outside these bounds, it is considered defective.

- 😀 Tolerances can be applied to both dimensions like diameter and to specific manufacturing processes like turning, where tools progressively reduce the size of a part.

- 😀 Fits between parts like shafts and holes can either be loose (clearance fit) or tight (interference fit) depending on the required application.

- 😀 A clearance fit occurs when the hole size is larger than the shaft size, allowing some movement, while an interference fit occurs when the shaft size is larger than the hole, requiring force to assemble.

- 😀 Tolerance limits define the 'maximum' and 'minimum' acceptable sizes for parts. For instance, a nominal diameter of 30 mm with a tolerance of ±0.25 mm would result in a size range of 29.75 mm to 30.25 mm.

- 😀 The concept of 'actual size' is the measured size of a part after manufacturing, which must fall within the defined tolerance range for the part to be considered acceptable.

- 😀 In some applications, like motor bearings, an interference fit is necessary to ensure parts stay securely in place, while clearance fits are used when some movement is acceptable or required.

- 😀 Tolerance not only helps with dimensional accuracy but ensures the functional compatibility of paired parts in mechanical assemblies.

Q & A

What is the definition of tolerance in manufacturing?

-Tolerance refers to the permissible limits of variation in a physical dimension, indicating the range within which a part's dimensions can vary while still being acceptable for its intended function.

Why is tolerance important in the manufacturing process?

-Tolerance is crucial because it ensures that parts fit together properly during assembly, maintaining both functional and technical integrity in the final product.

What does it mean when a part is within tolerance limits?

-When a part is within tolerance limits, it means that the part's dimensions are within the specified upper and lower limits, ensuring it can function as intended without issues during assembly.

What is the purpose of specifying a nominal size with tolerance?

-The nominal size represents the ideal or theoretical size of a part, while the tolerance specifies the permissible deviations from this nominal size, ensuring that the part still meets functional requirements even with slight variations.

What is the difference between clearance and interference fits?

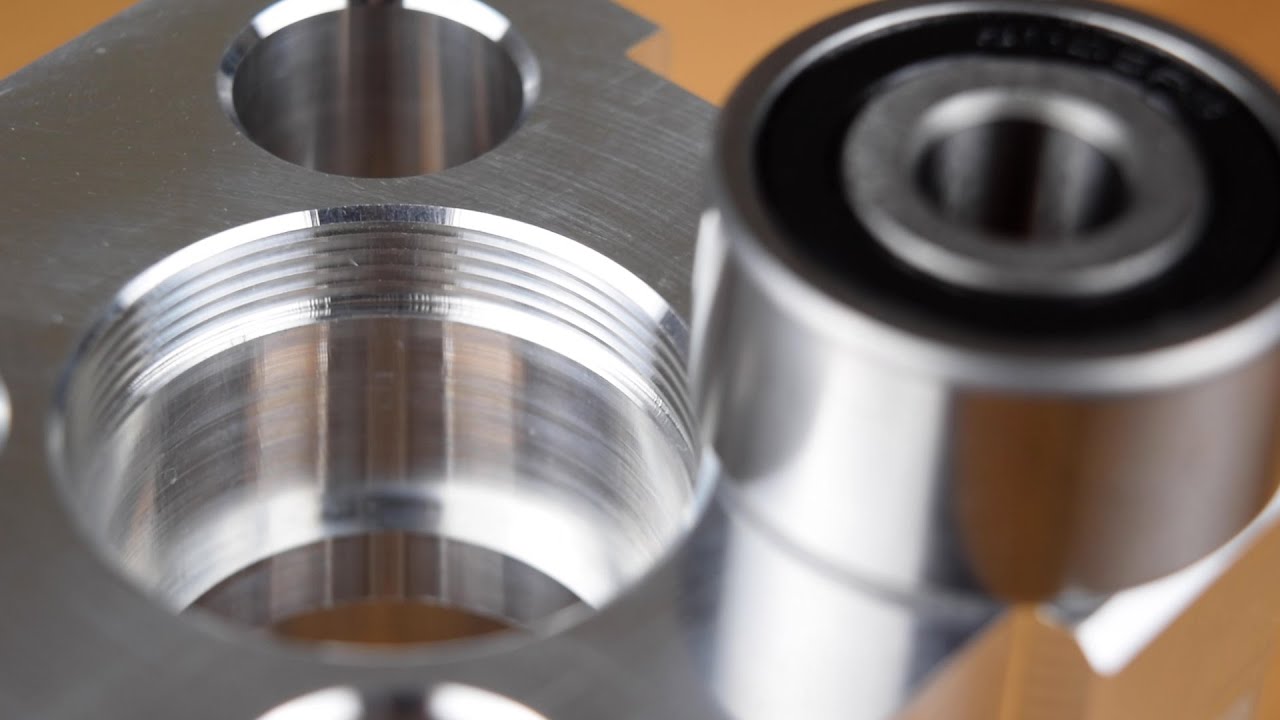

-Clearance fit occurs when the hole's diameter is larger than the shaft, allowing for easy movement or sliding. Interference fit, on the other hand, happens when the shaft is larger than the hole, creating a tight fit that may require force for assembly.

What is the role of the lathe in the manufacturing process described in the script?

-The lathe is used to machine a part, such as a shaft, by reducing its diameter from a larger size (e.g., 40mm) to a desired smaller size (e.g., 30mm), ensuring the part meets specified tolerance limits.

How are tolerance limits specified for a manufactured part?

-Tolerance limits are specified as an upper and lower bound around the nominal size, such as 30mm ± 0.25mm, where the upper limit could be 30.5mm and the lower limit could be 29.75mm.

What happens if a part does not meet the specified tolerance?

-If a part does not meet the specified tolerance, it is considered a failure, and the manufacturing process may need to be restarted to ensure the part falls within the acceptable range.

What are the terms 'clearance' and 'interference' used for in relation to fits?

-'Clearance' refers to the difference in size between a hole and a shaft when the hole is larger, allowing space for movement. 'Interference' refers to the situation where the shaft is larger than the hole, creating a tight fit.

Why is it important to have fits such as clearance and interference in engineering applications?

-Fits like clearance and interference are important for ensuring that parts function as intended, either allowing free movement (clearance) or creating a tight, secure connection (interference), depending on the application, such as in bearings or other mechanical systems.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Fits Chart - Shaft and Hole

Engineering tolerances - Fits (ISO)

Shock depan motor 3D ( cara kerja )

What is GD&T? | GD&T symbols Explained with Example | for Beginners Understanding | Subscribe Us

Fits and Tolerances: How to Design Stuff that Fits Together

Holier than Thou: Precision Holes by Drilling, Boring, and Reaming

5.0 / 5 (0 votes)