Pre Requisite Program || Pengantar Tujuan dan Latar Belakang || Part 1

Summary

TLDRIn this training session, Ikhsan from Indeso’s Quality Department introduces the concept of Pre-Requisite Programs (PRP) and its crucial role in food safety. The session covers two key objectives: understanding the basic requirements of a Food Safety Management System (FSMS) and fostering a responsive attitude toward food safety. Through real-life examples of food safety failures, such as contamination and product recalls, participants are encouraged to implement and prioritize food safety measures to ensure consumer well-being and uphold industry standards.

Takeaways

- 😀 Indeso is a company in the manufacturing and distribution of food ingredients, flavors, and fragrances.

- 😀 The focus of the training is on PRP (Pre-Requisite Program), essential for understanding food safety management systems (FSMS).

- 😀 There are two main goals in this training: understanding basic food safety requirements and implementing a culture of food safety.

- 😀 PRP is important for ensuring food safety, which directly impacts public health and consumer safety.

- 😀 The training emphasizes the importance of food safety to prevent contamination and ensure product safety.

- 😀 Examples of food safety failures include contamination of soft candy and nuts with foreign objects, like wires and nails.

- 😀 A notable case in Japan in 2000 involved a bacterial contamination in dairy products that resulted in over 14,000 people getting food poisoning.

- 😀 In 2004, a major jelly company in the U.S. was fined $20,000 due to a child being injured by a broken glass in their product.

- 😀 These examples highlight the serious consequences of food safety negligence in the food industry.

- 😀 The goal is for participants to understand and apply PRP as the foundation for ensuring food safety within their own roles at Indeso.

Q & A

What is the purpose of the training session?

-The training session aims to help participants understand the basic requirements for implementing a Food Safety Management System (FSMS) and to encourage a responsive and caring approach towards food safety in order to meet PRP (Prerequisite Program) standards at Indeso.

What is PRP, and why is it important for food safety?

-PRP stands for Prerequisite Program, which is a fundamental set of safety measures that are necessary before implementing the FSMS. It ensures the foundational practices for maintaining food safety across the production process.

What does the abbreviation GPRK stand for?

-GPRK stands for 'Gerakan Peduli Responsif Keamanan Pangan,' which translates to a movement for being responsive and caring about food safety. It is a simplified term used in place of PRP.

What examples of food safety violations were discussed in the training?

-Examples include contamination of soft candy and processed nuts with foreign objects like wires and screws, packaged vegetables containing a frog, complaints of nails in yogurt, and a major food poisoning incident in Japan due to *Staphylococcus aureus* bacteria in milk.

What happened in Japan in 2000 regarding food safety?

-In 2000, Japan faced a major food safety issue when contaminated milk, carrying *Staphylococcus aureus* bacteria, caused food poisoning, affecting more than 14,000 people.

What legal consequence did a jelly candy company in the U.S. face in 2004?

-In 2004, a jelly candy company in the U.S. was fined $20,000 after a child was injured by consuming a candy containing broken glass.

What is the expected outcome when consumers purchase food products?

-Consumers expect the food they purchase to be safe, free from any harmful foreign objects, and to meet health and safety standards.

What is the overall goal of implementing PRP within a company like Indeso?

-The goal of implementing PRP is to establish a reliable food safety management system that ensures the safety and quality of the products, preventing incidents that could harm consumers and damage the company's reputation.

How does PRP contribute to food safety in production processes?

-PRP serves as the foundation for a food safety management system, establishing basic safety practices that must be followed in all production stages to minimize risks of contamination and ensure product safety.

Why is food safety critical in the food manufacturing and distribution industry?

-Food safety is critical because any lapses in safety can lead to contamination, injuries, foodborne illnesses, and legal consequences, all of which can harm consumers and damage the company's credibility and trustworthiness.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

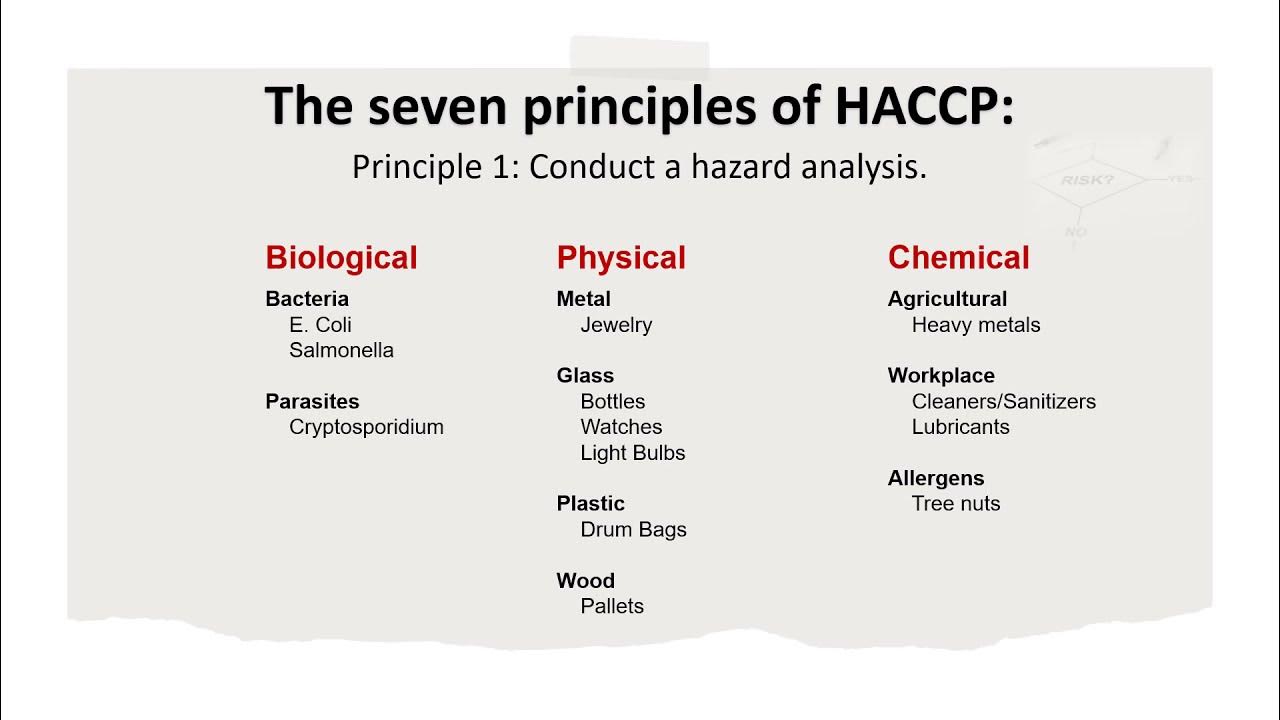

What is HACCP and what are the seven HACCP principles? HACCP Explained │ Food Safety

Let's Learn Food Science - Water Activity

APPLICATION OF WATER ACTIVITY

Pendahuluan Analisis Makanan dan Kosmetik

Programas de Autocontrole

STS - S&T Nation Building - Major development programs and personalities in S&T in the Philippines.

5.0 / 5 (0 votes)