The farming robots that will feed the world | Hard Reset

Summary

TLDRThe video script introduces a revolutionary robot farmer developed by Dogtooth, a company co-founded by Duncan, who has a background in machine learning and computer vision. The robot, designed to address labor shortages in the agricultural sector, is capable of delicately picking soft fruit like strawberries, a task previously only performed by humans. The U.K., facing a significant labor shortage for fruit picking, resulting in substantial fruit waste and economic loss, stands to benefit greatly from this technology. The robot's sophisticated arm, custom-designed for the task, uses stereo cameras and computer vision to navigate the farm environment, identify, and harvest the fruit. The technology not only picks fruit but also inspects it for quality, sorting it into waste or retail containers. While the current generation of robots works slower than humans, they are designed for endurance, capable of operating through multiple shifts without fatigue. The robots are also mobile, with some being shipped to Tasmania for seasonal work, highlighting the potential for global agricultural support. The script discusses the broader implications of robotic automation on labor markets and the environment, suggesting that if managed correctly, this technology could create more desirable jobs for humans while reducing the carbon footprint of food production.

Takeaways

- 🤖 **Robotic Innovation in Farming**: The development of robots capable of delicate tasks like picking soft fruit is a significant advancement in agricultural automation.

- 🇬🇧 **UK's Agricultural Challenge**: There is a shortage of human labor for fruit picking in the UK, leading to significant waste and economic loss.

- 🍓 **Precision Picking**: Robotic systems are designed to be smart and dexterous to pick strawberries without damaging them, which is crucial for fruit quality.

- 🚜 **Beyond Tractors**: While farms already use automated technologies like GPS-guided tractors, the new robots represent a leap to handling more complex and delicate tasks.

- 🤓 **Interdisciplinary Founders**: The co-founders of Dogtooth come from diverse backgrounds, including machine learning and computer vision, which is instrumental in creating the robots.

- 🧼 **Custom Design Necessity**: Due to the unique demands of farming, most components of the robots, including the arms, had to be custom designed and built from scratch.

- 📈 **Data-Driven Agriculture**: The robots harvest not only fruit but also data, which can be used to improve yield prediction and farming practices.

- 🌱 **Seasonal Workforce Supplement**: The aim is not to replace human workers but to assist in tasks that are difficult to staff, such as seasonal fruit picking.

- 🌍 **Global Workforce**: These robots are designed to be mobile and work in different environments worldwide, even spending parts of the year in Australia.

- 🔄 **Environmental Impact**: By enabling local production of crops, the use of robots could reduce the carbon footprint associated with transporting produce over long distances.

- ⚙️ **Future of Work**: The integration of robotics in labor raises questions about the future of human jobs, emphasizing the need to find a balance between automation and human employment.

Q & A

What is the primary function of the robot farmer developed by Dogtooth?

-The primary function of the robot farmer is to pick soft fruit like strawberries, which is a task that requires a high level of dexterity and precision.

Why is it challenging to find human labor for harvesting strawberries in the U.K.?

-It is challenging to find human labor for harvesting strawberries in the U.K. due to a labor shortage, which has led to significant fruit wastage and financial loss for the farming industry.

How does the robot's arm work in terms of positioning and movement?

-The robot's arm can move to any position in 3D space and approach the target from any angle, allowing it to handle delicate tasks such as picking strawberries without damaging them.

What is the significance of the cameras and LED lights in the robot's pickerhead?

-The cameras in the pickerhead allow the robot to see the fruit in 3D, enabling it to identify and pick the correct berry. The LED lights enable the robot to operate and pick fruit even in low-light conditions, such as at night.

How does the robot determine whether a picked berry should be considered waste or ready for retail?

-After picking a berry, the robot suspends it in an inspection chamber with cameras and consistent lighting to view the berry from all angles. It can detect up to 17 different types of defects, which helps it decide whether to discard the berry or place it in a punnet for retail.

What is the current speed of the robots compared to human pickers?

-The current generation of robots is about a quarter of the speed of an average human picker. However, they can operate for multiple shifts, allowing them to pick as much fruit as a person can in a day.

How do the robots avoid bruising the strawberries during the picking process?

-The robots avoid bruising the strawberries by picking from the stem rather than grabbing the berry itself. This technique also helps prevent the spread of fungus or other pests.

What is the potential impact of robotic automation on the labor market in farming?

-Robotic automation could help address labor shortages and increase efficiency in farming. However, it also poses a threat of displacing human workers, potentially leading to a significant labor disruption if not managed correctly.

How does the robot's design allow it to work in different environments, such as flat farms and steep hillsides?

-The robot is designed to be super rugged with super rugged tracks, enabling it to operate in various terrains, from flat farms to steep hillsides, even in challenging weather conditions.

What is the purpose of the robots being designed to work out of shipping containers?

-The robots are designed to work out of shipping containers to facilitate their transportation and use in different geographical locations. This allows for more efficient and environmentally friendly operation, as it is cheaper to ship robots than human workers.

How does the data collected by the robots contribute to improving farming practices?

-The robots collect about 40 gigabytes of data every day, which can be integrated with weather forecasting to create a yield prediction model. This helps in predicting not just what's ready to pick today, but also what will be ready in the future, leading to more precise and efficient farming practices.

What is the broader vision for the application of robotic intelligence beyond farming?

-The intelligence developed for farming robots has the potential to be applied to other dynamic and inconsistent environments like stores, hospitals, or homes. In theory, there's almost no physical job a robot couldn't do, which could lead to a transition in how physical labor is perceived and managed.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Robo-UV: Deepjyoti's Nath entrepreneurial story PL

Siddharth Mall, Playment talking about their innovation at AGBA 2019, 2nd Jury Round

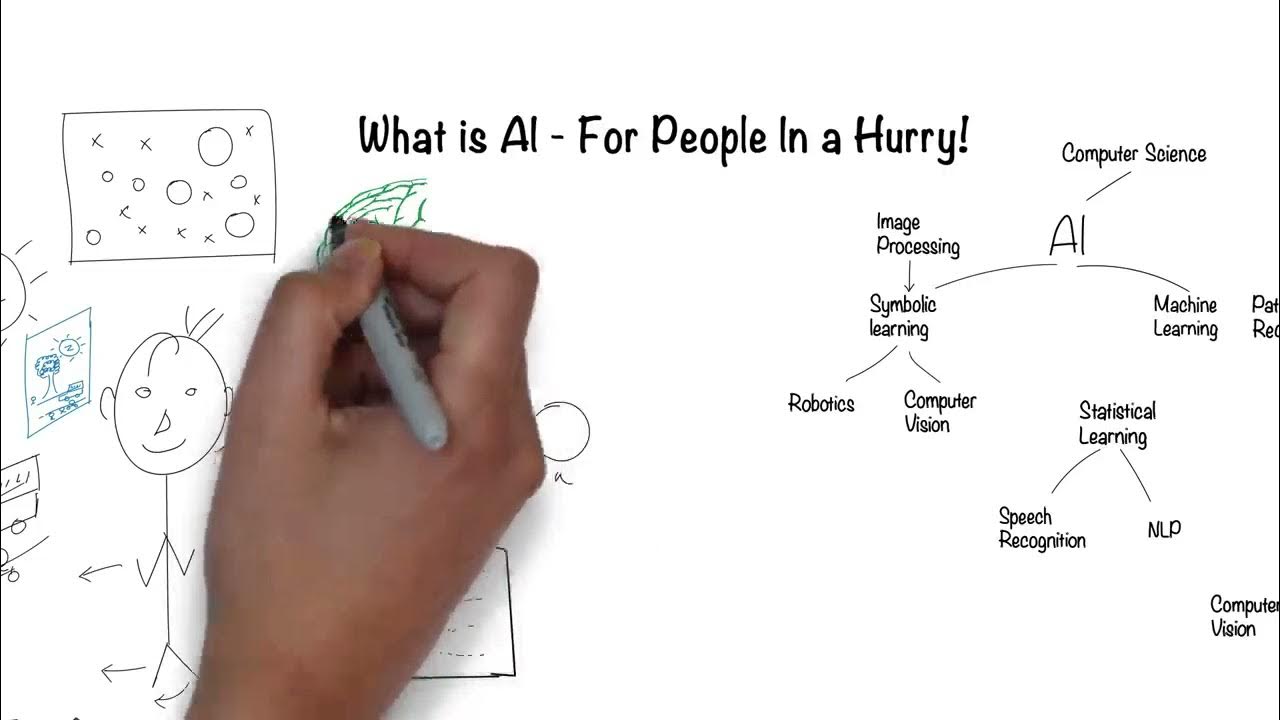

Artificial Intelligence (AI) for People in a Hurry

UNIMATE - ROBOT

Object Detection Using OpenCV Python | Object Detection OpenCV Tutorial | Simplilearn

Amazon in the Classroom

5.0 / 5 (0 votes)