HACCP GMP Video

Summary

TLDRThe script introduces HASIP (Hazard Analysis Critical Control Point), a food safety system developed for NASA that's now used globally from farm to fork. It identifies and controls four types of food hazards: allergenic, biological, chemical, and physical. HASIP is preventative, integrating safety into every food production step, and requires good manufacturing practices. The script outlines HASIP's seven principles, emphasizing its role in ensuring food safety, enhancing a plant's competitive advantage, and building consumer confidence.

Takeaways

- 🔬 **HASIP Definition**: HASIP stands for Hazard Analysis Critical Control Point, a system developed for NASA to ensure food safety.

- 🌐 **Global Application**: HASIP is used worldwide from farm to fork, indicating its broad application in food safety.

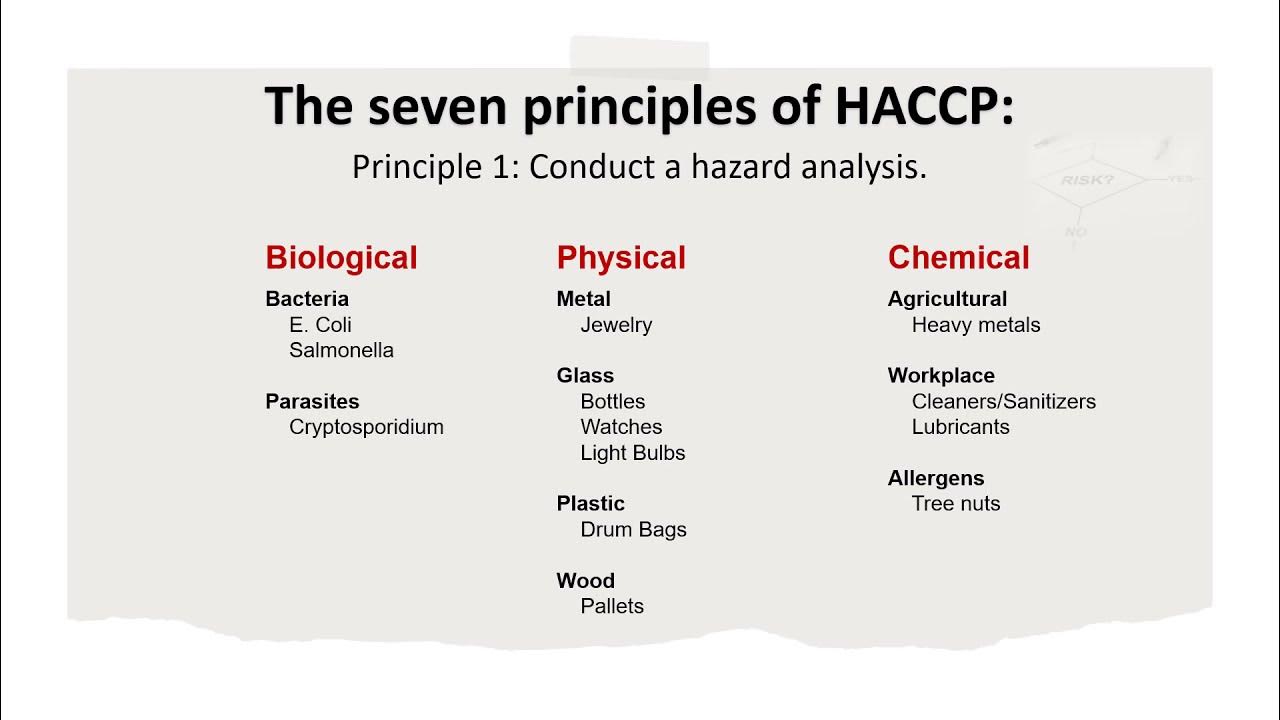

- 🛡️ **Safety from Various Hazards**: HASIP helps control chemical, physical, microbiological, and allergy-related hazards in food processing.

- 🥚 **Allergenic Hazards**: Examples include eggs, shellfish, nuts, soy, wheat, sesame seeds, sulfites, and milk.

- 🦠 **Biological Hazards**: Include illness-causing bacteria like Salmonella or E.coli, viruses, parasites, and molds.

- 🧪 **Chemical Hazards**: Include cleaning compounds, pesticides, preservatives, antibiotics, and incorrectly added food ingredients.

- 🔩 **Physical Hazards**: Include foreign objects like glass, metal, stones, wood splinters, or bone pieces.

- 🔄 **Preventative System**: HASIP is a preventative control system that identifies potential food safety problems and shows how to prevent them.

- 📈 **Prerequisite Programs**: Good Manufacturing Practices (GMPP) are prerequisites for HASIP, ensuring a safe environment for food processing.

- 📋 **Documentation and Records**: HASIP requires detailed documentation and record-keeping for monitoring, deviations, and corrective actions.

- 🌟 **Competitive Advantage**: HASIP increases a processing plant's competitive advantage by ensuring product safety and reliability.

Q & A

What does HASIP stand for?

-HASIP stands for Hazard Analysis Critical Control Point.

For what purpose was HASIP initially developed?

-HASIP was initially developed for the NASA space program to ensure food safety.

How is HASIP used in the food industry?

-HASIP is used from farm to fork, covering animal and crop production, processing, food distribution, and retail food service.

What are the four types of hazards that HASIP helps to control?

-The four types of hazards are allergenic hazards, biological hazards, chemical hazards, and physical hazards.

What is the role of Good Manufacturing Practices (GMP) in relation to HASIP?

-GMP is a prerequisite that addresses hazards associated with the environment where food is processed, and it must be in place before a HASIP system can work effectively.

What are the seven principles of the HASIP system?

-The seven principles are: 1) Conduct a hazard assessment, 2) Determine critical control points (CCPs), 3) Establish critical limits, 4) Establish and implement monitoring procedures, 5) Take prompt corrective action, 6) Establish verification procedures, and 7) Establish documentation and record-keeping procedures.

Why is it important to determine critical control points in the HASIP system?

-Determining critical control points is important because if control is lost at these points, it's likely that human health will be compromised.

What must be met at each critical control point in HASIP?

-Critical limits must be met at each CCP, which are the parameters that ensure the CCP effectively controls the hazard.

How does monitoring play a role in the HASIP system?

-Monitoring involves systematically observing, measuring, and recording the most important factors needed for control to ensure that the critical limits set for each CCP are being met.

What is the purpose of corrective actions in HASIP?

-Corrective actions are taken whenever monitoring indicates that limits are not met, to prevent potential risks to human health.

Why is documentation and record-keeping important in HASIP?

-Documentation and record-keeping are important for showing whether correct processing conditions are being completed and for properly correcting any out-of-control processes.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

HACCP - Making Food Products Safe, Part 1

What is HACCP? | Food Safety Risks & Hazards | SafetyCulture

What is HACCP and what are the seven HACCP principles? HACCP Explained │ Food Safety

Mudah !!! HACCP 5 langkah pendahuluan & 7 Prinsip

HACCP Training for the Food Industry from SafetyVideos.com

HACCP -Making Food Products Safe, Part 2

5.0 / 5 (0 votes)