Lecture 18 : Systemic Approach to Biomed Innovations by Prof. B. Ravi Part 2

Summary

TLDRThis transcript outlines a comprehensive 16-step process for medical device innovation, emphasizing the importance of a multidisciplinary team, clinical immersion, and problem definition. It covers concept feasibility, design, prototyping, quality management, testing, and certification. The speaker also discusses intellectual property rights, business models, funding stages, and the necessity of continuous improvement post-market deployment.

Takeaways

- 🔬 **Multidisciplinary Teams**: A medical device innovation team should include experts in Bio (like doctors or biomedical engineers), creative designers (like industrial or product designers), electronics (including electrical, computer science, software, IT), and mechanical (manufacturing, materials).

- 🏥 **Clinical Immersion**: Understanding the real needs and pain points of medical professionals requires observing hospital procedures and engaging in meaningful dialogues, ensuring respect for patient privacy and obtaining necessary permissions.

- 🤔 **Root Cause Analysis**: Asking 'Why' multiple times helps in identifying the root cause of a problem, which can lead to more effective solutions than merely addressing symptoms or creating cheaper versions of existing devices.

- 📝 **Clear Problem Definition**: A well-defined problem statement should be concise, specific, and not solution-oriented, focusing on the desired outcome, clinical need, and target domain.

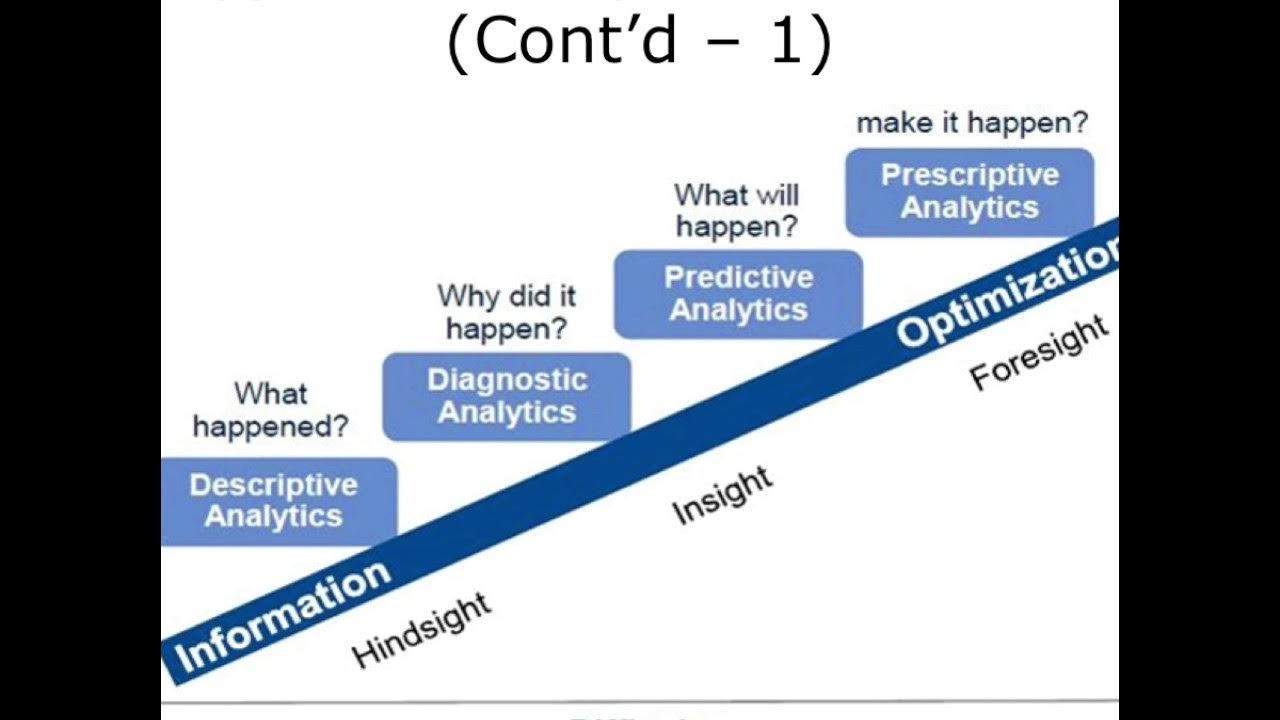

- 🚀 **Concept and Feasibility**: Concepts should be evaluated against market demand, value proposition, capability to execute, and the commitment of the innovator and stakeholders.

- ⚙️ **Detailed Design and Prototyping**: The design phase involves considering the structure, components, materials, geometry, and manufacturing process, followed by creating physical and functional prototypes.

- 🔬 **Quality Management**: Implementing a quality management system ensures standard operating procedures, documentation, and traceability, which are crucial for medical device development.

- 🧪 **Lab and Animal Testing**: Before human trials, devices undergo rigorous lab testing for biocompatibility, mechanical integrity, and electromagnetic compatibility, and may also be tested on animals under strict regulations.

- 🩺 **Human Clinical Trials**: Trials on human subjects are conducted with informed consent, focusing on safety, efficacy, sensitivity, and specificity, with strict inclusion and exclusion criteria.

- 🏢 **Certification and Licensing**: The process of obtaining certification and licensing involves submitting comprehensive documentation and undergoing inspections to ensure the device's safety and efficacy.

- 💼 **Business Model and Funding**: A successful business model in the medical device industry requires a clear understanding of the offering, customers, supply chain, and funding strategies at different stages of the company's growth.

- 🔁 **Continuous Improvement**: Post-deployment, gathering customer feedback is essential for the continuous improvement and innovation of the product, ensuring it meets market needs and evolves over time.

Q & A

What are the four critical disciplines needed in a medical device innovation team?

-The four critical disciplines needed are: 1) Biology (a doctor or biomedical engineer with knowledge of human anatomy), 2) Design (an industrial or product designer with a creative mindset), 3) Electronics (expertise in electronics, electrical, computer science, or software), and 4) Mechanical (knowledge in mechanical engineering, manufacturing, materials, etc.).

Why is clinical immersion important in the development of medical devices?

-Clinical immersion is crucial to understand the real problems that doctors face, identify existing solutions, and determine the actual pain points. It involves visiting hospitals, observing procedures, and talking to doctors to gain insights that cannot be obtained otherwise.

What should be considered when observing hospital procedures during clinical immersion?

-During observation, one should consider the devices used, the time taken for diagnosis or treatment, the skill level of doctors, patient variations, complications, and overall comfort levels. It's also important to respect patient privacy and obtain necessary permissions.

Why is asking 'why' multiple times important in defining a problem in medical device innovation?

-Asking 'why' multiple times helps to delve deeper into the root cause of a problem, potentially leading to more innovative and effective solutions rather than just creating a cheaper version of an existing device or addressing a superficial issue.

What are the three criteria a problem definition in the medical domain should satisfy?

-A problem definition should be clear, not vague, should not point to a specific solution but define the problem, and should lead to the root cause after multiple 'why' questions.

What are the four filters to evaluate a concept's feasibility in medical device innovation?

-The four filters are: 1) Significant local market requirement, 2) A value proposition that offers a substantial improvement, 3) Capability to execute the idea with available resources and skills, and 4) Full-time commitment from the innovator and stakeholders.

How does the detailed design process in medical device development consider functionality and materials?

-The detailed design process evaluates the overall structure, components, materials, and geometry based on the required functionality and features. Different components may require different materials due to their specific functions, such as biocompatibility for implants or low friction for moving parts.

What role do CAD and FEA software play in the development of medical devices?

-CAD software is used for visualization, modeling, and designing the device's geometry. It also allows for motion and assembly sequencing analysis. FEA software simulates loads on components to analyze stresses and strains, which is crucial for optimizing the design.

Why is it necessary to create a physical prototype in the development of medical devices?

-A physical prototype is necessary to check the form, fit, and partial functionality of the device. It helps identify any design flaws or manufacturing issues before full-scale production begins.

What are the key aspects of quality management in medical device innovation?

-Quality management involves maintaining standard operating procedures, documentation, and records to ensure traceability and accountability. It is essential for identifying issues, maintaining safety standards, and meeting regulatory requirements.

What are the different stages of testing that a medical device undergoes before reaching the market?

-Medical devices undergo lab testing for biocompatibility, mechanical testing, and electromagnetic compatibility. If necessary, animal trials are conducted, followed by human clinical trials to ensure safety and efficacy.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)