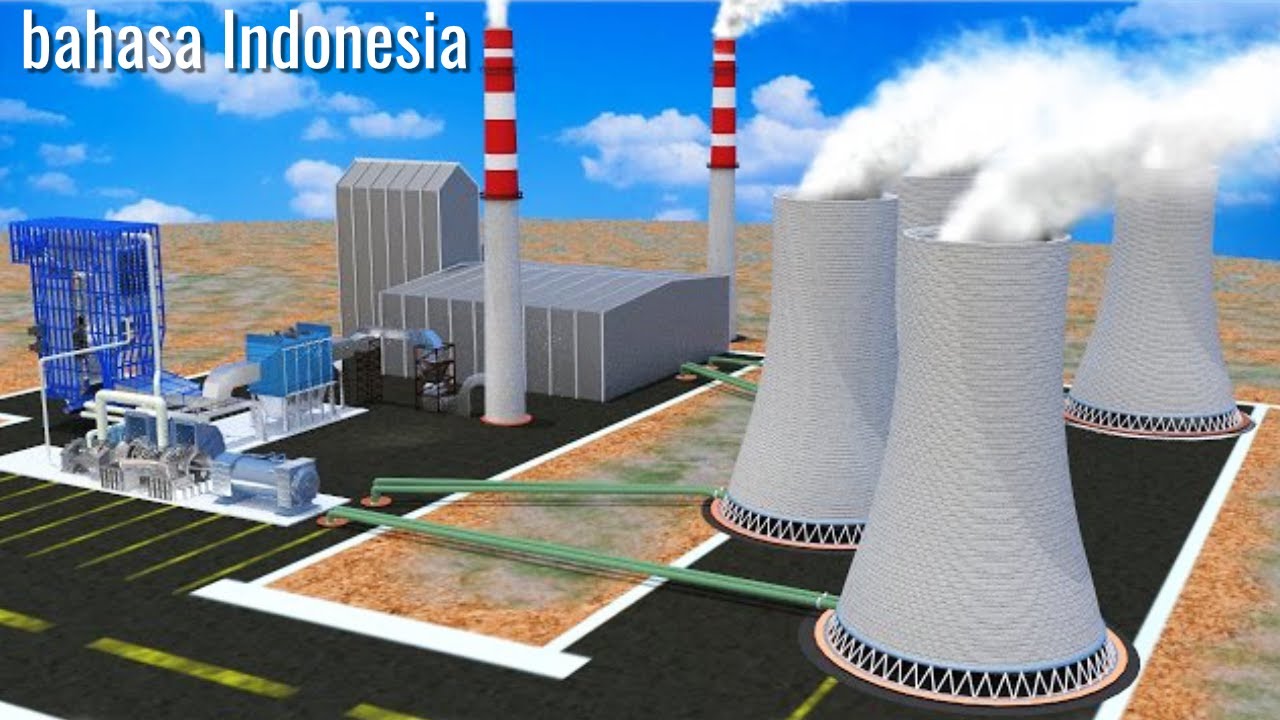

How do you generate electricity using coal - animated video

Summary

TLDRThis video explains how First Energy generates electricity at its coal-fired power plants in the Northeast U.S., which serve over 4 million customers. It describes the process of converting coal into electricity through pulverizing, heating, and generating steam that powers turbines. Environmental protection systems are highlighted, including scrubbers to remove pollutants like sulfur dioxide, recycling fly ash, and converting byproducts into gypsum for drywall. The video also discusses how electricity is transmitted from the plant to homes and businesses via transformers and substations.

Takeaways

- ⚡ First Energy operates 20 power plants in the Northeast U.S., producing 70 million megawatt-hours of electricity annually for over 4 million customers.

- 🔥 Over half of First Energy’s electricity is generated from coal, which is higher than the national average of 60%.

- 🏭 The power plant highlighted in the script produces over 2,000 megawatts, enough to supply electricity to 1.5 million homes and businesses.

- 🚂 Coal is delivered to the plant mainly by barge, rail, and truck, with the plant consuming 21,000 tons of coal daily.

- 🌬️ Pulverized coal is mixed with warm air and burned in a boiler to create steam, which drives turbines to generate electricity.

- 💨 After generating electricity, steam is cooled and condensed in a condenser using water from cooling towers, allowing the process to repeat.

- 💡 Environmental control systems, including scrubbers and selective catalytic reduction (SCR), are used to reduce pollutants like sulfur dioxide and nitrogen oxides.

- 🧱 Byproducts like calcium sulfite are converted into gypsum, which is used to make drywall, and fly ash is recycled into products like concrete and roofing materials.

- 🔋 Transformers outside the plant increase the voltage to 345,000 volts for long-distance transmission, with substations reducing voltage for distribution to homes and businesses.

- ♻️ First Energy recycles half a million tons of gypsum annually, contributing to the construction of wallboards for 70,000 new homes.

Q & A

How many power plants does First Energy operate in the Northeast United States?

-First Energy operates 20 power plants in the Northeast United States.

What is the approximate annual electricity production of First Energy's power plants?

-First Energy's power plants produce nearly 70 million megawatt hours of electricity each year.

What percentage of First Energy's electricity is produced by using coal?

-Over half of First Energy's electricity is produced by using coal.

How much electricity does one power plant similar to those operated by First Energy produce at full capacity?

-One power plant can produce more than 2000 megawatts of electricity at full capacity.

What is the approximate amount of coal used by the plant each day?

-The plant uses about 21,000 tons of coal each day.

How does the plant transport coal into the facility?

-Coal is transported into the plant via a four-mile long conveyor that can carry up to 900 tons of coal per hour.

What is the role of pulverizers in the coal power generation process?

-Pulverizers grind coal into a fine powder, which is then blown into the boiler with warm air.

What is the temperature of the steam generated in the boiler?

-The temperature of the steam generated in the boiler is about 1,000 degrees Fahrenheit.

How does the plant convert thermal energy into mechanical energy?

-The plant converts thermal energy into mechanical energy at the turbine, where high-pressure steam turns a series of turbines.

What is the electrical charge created by the generator at the plant?

-The generator continuously creates an electrical charge of 34,481 amps at 18,000 volts of electricity.

How does the plant handle the byproduct calcium sulfite created during the scrubbing process?

-First Energy turns the byproduct calcium sulfite into a valuable building material called gypsum, which is used to make wallboard or drywall.

What is the role of selective catalytic reduction (SCR) technology in reducing nitrogen oxide emissions?

-SCR technology reduces nitrogen oxide emissions by converting them into water vapor and pure nitrogen through a reaction with ammonia.

How does the plant increase the voltage of electricity for long-distance transmission?

-Transformers located just outside the plant boost the power from 18,000 volts to 345,000 volts for long-distance transmission.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

How do coal-fired power stations work?

Bagaimana cara kerja pembangkit listrik tenaga termal/uap?

Guru Listrik Online : Sistem Pembangkitan, Transmisi dan Distribusi Listrik

Sering Digunakan Tapi Gak Tau Prosesnya? Begini Cara Kerja Pembangkit Listrik Tenaga Air, Bayu & Uap

PLTU

How does a Thermal power plant work?

5.0 / 5 (0 votes)