Lezione 4A - CREAZIONE VSM - Parte 1 di 4 - Lean Thinking e Toyota Producition System - Zero sprechi

Summary

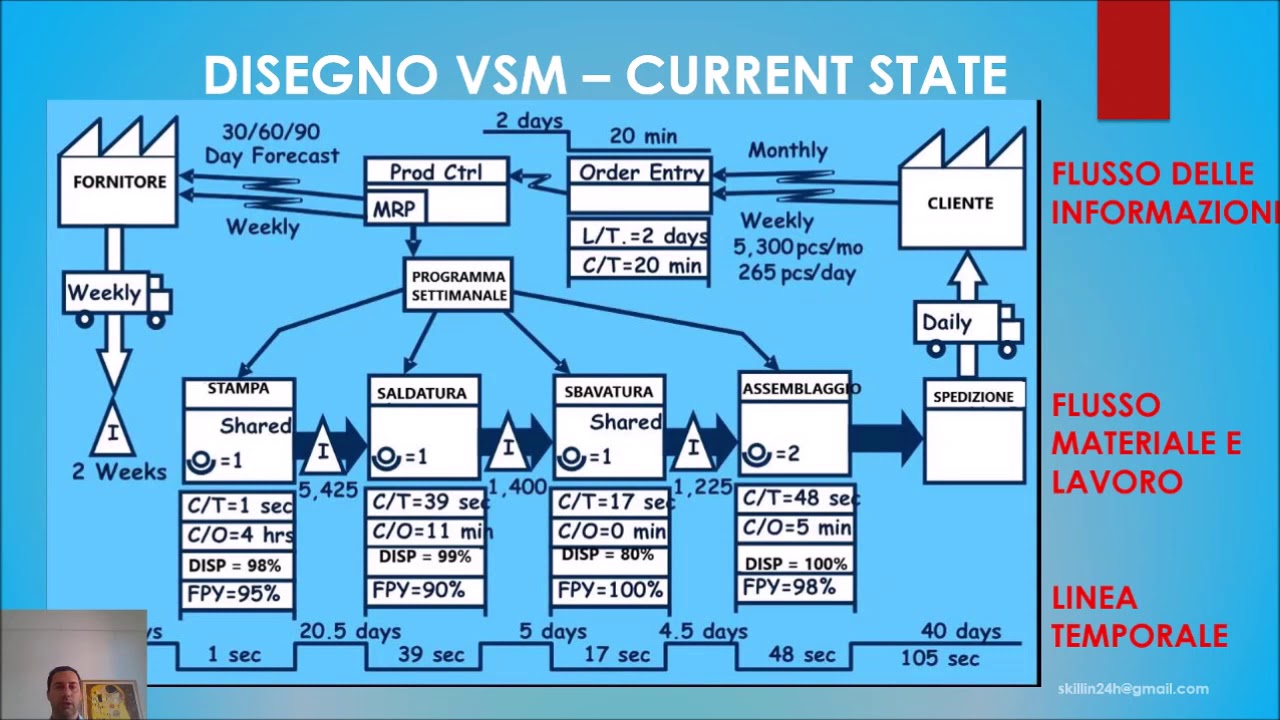

TLDRThis script outlines an in-depth course on business strategy and organization, focusing on the Toyota Production System's value stream mapping. It details a three-step process: preparation, study, and implementation, taking approximately four weeks. The study phase involves a three-day full-time workshop with a team to create a current state map and a desired future state map. The goal is to identify and eliminate waste, requiring a diverse team with a mix of experience and fresh perspectives. The script emphasizes the importance of data collection, including production times, inventory, and quality, to create an effective value stream map.

Takeaways

- 📈 The lecture focuses on the Toyota Production System and the creation of a business stream map.

- 🔍 The value stream map is a detailed representation of the activities required to transform a customer request into a product or service.

- 🛠️ The process involves three stages: preparation, study, and implementation, with the study phase being the most concrete and conducted over three full-time days in the company.

- 👥 A diverse team of 5-10 members, including a leader, is essential for the project's success, with members having different backgrounds and perspectives.

- 🏢 The team should include individuals who are familiar with the process and those who can view the business with fresh eyes.

- 📚 Basic training on lean tools is necessary for the team, especially for capturing data and identifying waste.

- 🔎 Data collection includes observing the business process, interviewing personnel, and gathering information on material flow, cycle time, setup time, and performance metrics.

- ⏱️ The study phase involves creating a current state map to understand the business's current operations and identifying areas for improvement.

- 📊 The team must respect the timeline of the three-day study phase, which is crucial for the effectiveness of the process.

- 🚀 The implementation phase follows the study phase, where a plan is designed based on the insights gained during the study phase.

- 🗂️ Documentation and information flow within the company are also important aspects to consider during the data collection process.

Q & A

What is the main focus of the course described in the transcript?

-The main focus of the course is on business stream creation within the context of organizational strategy, with a detailed exploration of the Toyota Production System and value stream mapping.

Why is the course edition described as 'particularly long'?

-The course edition is described as 'particularly long' because it covers an in-depth treatment of designing and creating a business stream, which involves extensive episodes or videos.

What is the significance of the Toyota Production System in the course?

-The Toyota Production System is significant as it provides the methodological framework for understanding value from the customer's perspective and for mapping the value stream within a business.

What are the three phases involved in creating a value stream map?

-The three phases involved in creating a value stream map are the preparatory phase, the study phase, and the implementation phase.

How long is the preparatory phase for creating a value stream map?

-The preparatory phase for creating a value stream map is approximately four weeks long.

What is the duration of the study phase in the value stream mapping process?

-The study phase is conducted over three full-time days in the company with a team of intervention.

What is the purpose of the second day in the study phase of value stream mapping?

-The purpose of the second day in the study phase is to create the current state map, which is a detailed representation of how the business operates at that moment.

What is the role of the training provided during the value stream mapping process?

-The training provided during the value stream mapping process is to help identify and understand waste within the business processes, which is essential for subsequent implementation and improvement.

What is the ideal team composition for conducting a value stream mapping exercise?

-The ideal team composition for conducting a value stream mapping exercise consists of five to ten members, including a leader responsible for implementation and problem-solving.

Why is it important for team members to have diverse backgrounds and experiences in value stream mapping?

-Diverse backgrounds and experiences among team members are important because they bring different perspectives and insights, which can help uncover hidden waste and lead to more effective process improvements.

What types of data are collected during the value stream mapping process?

-During the value stream mapping process, data collected includes lead times, cycle times, setup times, inventory levels, production schedules, quality metrics, and any other relevant information that can help identify waste and inefficiencies.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is Lean manufacturing? 5 functions of Lean Manufacturing | Lean Production

Operations Management Chpt. 7 Palmer

MANAJEMEN OPERASIONAL (STRATEGI PROSES)

Lezione 4C - CREAZIONE VSM - Parte 3 di 4 - Lean Thinking e Toyota Producition System - Zero sprechi

Value Chain Management explained in 11 minutes

【テレ東・豊島晋作の聞く技術】上司より話の長い人が出世できない理由/「何故を5回繰り返せ」トヨタウェイから学んだ本質/心を掴むには人のストーリーを理解せよ【MANAGEMENT SKILL SET】

5.0 / 5 (0 votes)