Remeha Elga Ace - plaatsing & installatie (volledige instructievideo)

Summary

TLDRThis comprehensive video script provides detailed instructions for the installation of an outdoor unit and an indoor unit (LK IS) for a heating system. It covers crucial aspects such as selecting suitable locations, maintaining proper distances from walls, ensuring proper condensation drainage, and implementing vibration dampeners. The script guides through the electrical connections, including power cables, connections between indoor and outdoor units, and thermostats. Additionally, it explains the refrigerant line setup, hydraulic connections, flushing the system, and integrating the indoor unit with the boiler. The script emphasizes crucial steps like positioning filters, cable routing, and parameterization, ensuring a seamless and efficient installation process.

Takeaways

- 🏡 The outdoor unit must be placed in a suitable location, maintaining the minimum distance from walls as specified in the installation manual.

- 💧 Ensure proper drainage for the condensation water from the outdoor unit, e.g., by placing it above a gravel bed.

- 🔊 Use appropriate vibration dampers during installation to prevent noise pollution.

- ⚡ Follow the correct sequence for electrical connections: power cable, work switch, connection between indoor and outdoor units (using only four connectors), and outdoor sensor placement.

- 🔩 Properly solder or crimp the refrigerant line couplings before connecting them to the outdoor unit.

- 📍 Choose a suitable location for the indoor unit (close to the boiler), considering hydraulic connections and access for maintenance.

- 🔧 Mount the indoor unit by first securing the back plate to the wall, then hanging the unit on the plate.

- 🚰 Connect the refrigerant lines to the indoor unit, ensuring proper sealing with gaskets.

- 💨 Evacuate the refrigerant circuit after connecting the lines, following the commissioning video instructions.

- 🔌 Connect the indoor unit to the outdoor unit, boiler, thermostat, and power supply, following the correct wiring sequence and using cable binders for tidy cable management.

Q & A

What is the importance of proper placement of the outdoor unit?

-The outdoor unit must be placed in a suitable location, considering the minimum distance required from walls as specified in the installation manual. This ensures proper airflow and prevents obstructions.

How should the condensation water from the outdoor unit be handled?

-The condensation water from the outdoor unit should not be allowed to accumulate on the ground. It is recommended to place the unit above a gravel bed or other drainage solution to ensure proper drainage of the condensation water.

Why is it important to use vibration dampers during installation?

-Vibration dampers should be used during installation to prevent noise pollution and minimize disturbance caused by the operation of the outdoor unit.

What are the steps involved in making electrical connections for the outdoor unit?

-First, the power cable is run, and the work switch is mounted. Next, the electrical connection between the indoor unit (LK) and the outdoor unit is made, using only four connectors (the two left connectors are not connected). Finally, the outdoor temperature sensor is connected to the LK.

What should be considered when selecting the location for the indoor unit (LK)?

-When choosing the location for the indoor unit (LK), attention should be paid to the proximity to the boiler and the hydraulic connections, ensuring proper placement and accessibility.

What is the purpose of the blind caps on the LK, and what should be checked?

-The blind caps on the LK should be removed, and it should be checked if the system is properly sealed, ensuring no leaks.

Why is it recommended to install a dirt filter during the hydraulic connections?

-A dirt filter should be installed during the hydraulic connections to prevent any dirt or debris from the central heating system from entering the LK, ensuring proper functioning and preventing potential damage.

What are the steps involved in making electrical connections between the LK and the outdoor unit?

-First, the power cable is connected to the LK. Then, the LK and the central heating boiler are connected via the OpenTherm connector. The outdoor temperature sensor is connected to the Temp connector, and finally, the thermostat is connected to the LK via the EIB connector.

What should be done if a new thermostat needs to be installed?

-If a new thermostat needs to be installed, it should be done during the electrical connections phase, following the same procedure of connecting it to the LK via the EIB connector.

Where can additional information about the parameterization and commissioning of the LK be found?

-The script mentions that additional videos covering the parameterization and commissioning of the LK should be consulted for more detailed information.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

PERANGKAT UTAMA ODU & IDU PADA VSAT - SISTEM KOMUNIKASI SATELIT - SMK KPM - tugas AIJ/ASJ - XII TKJ

Smart Wifi Mini Door Bell with Ringer and Mobile App

अपने घर में AC लगवाते हुए इन बातों का ध्यान जरूर रखें Split AC Installation Tips in Hindi Emm Vlogs

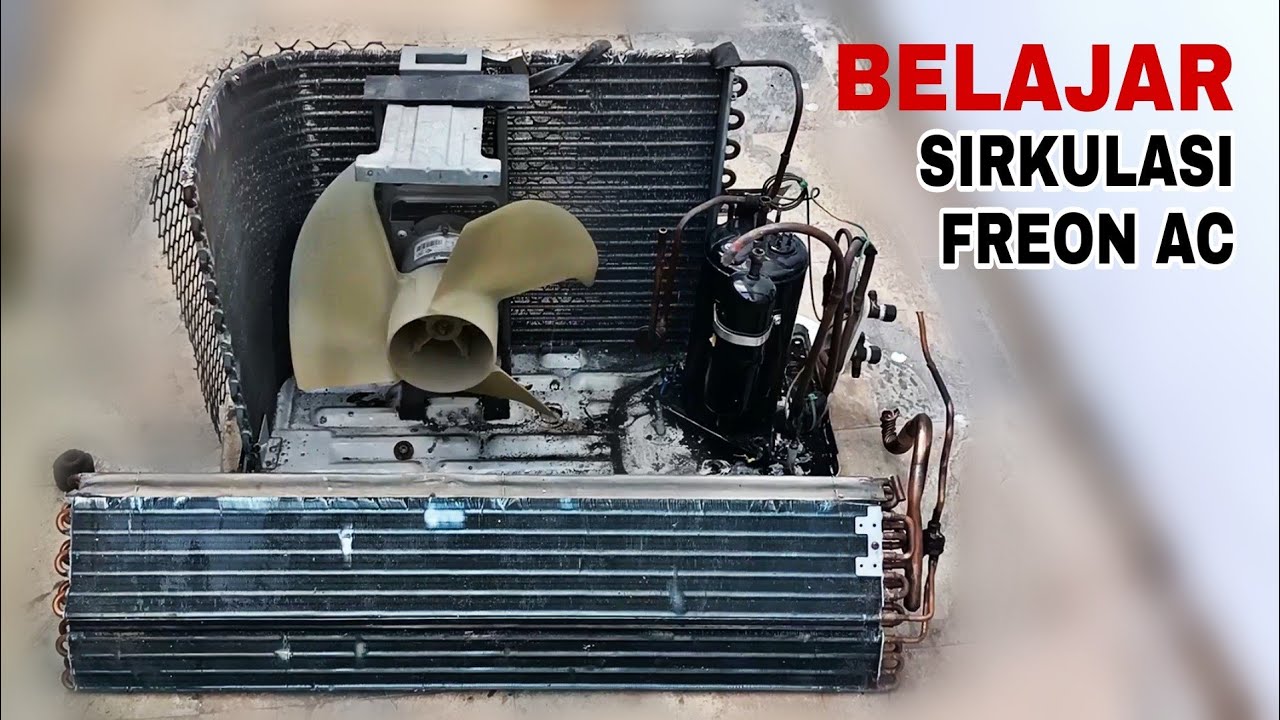

Belajar sirkulasi freon AC untuk pemula agar bisa servis atau perbaiki AC

Heating and Cooling VRF System

Volkswagen Jetta 2014 - Apple Carplay, Android Auto магнитола, камера заднего вида, кодировка

5.0 / 5 (0 votes)