PART-1: Technical Evaluation of Centrifugal Pump Mechanical Datasheet with respect to API 610

Summary

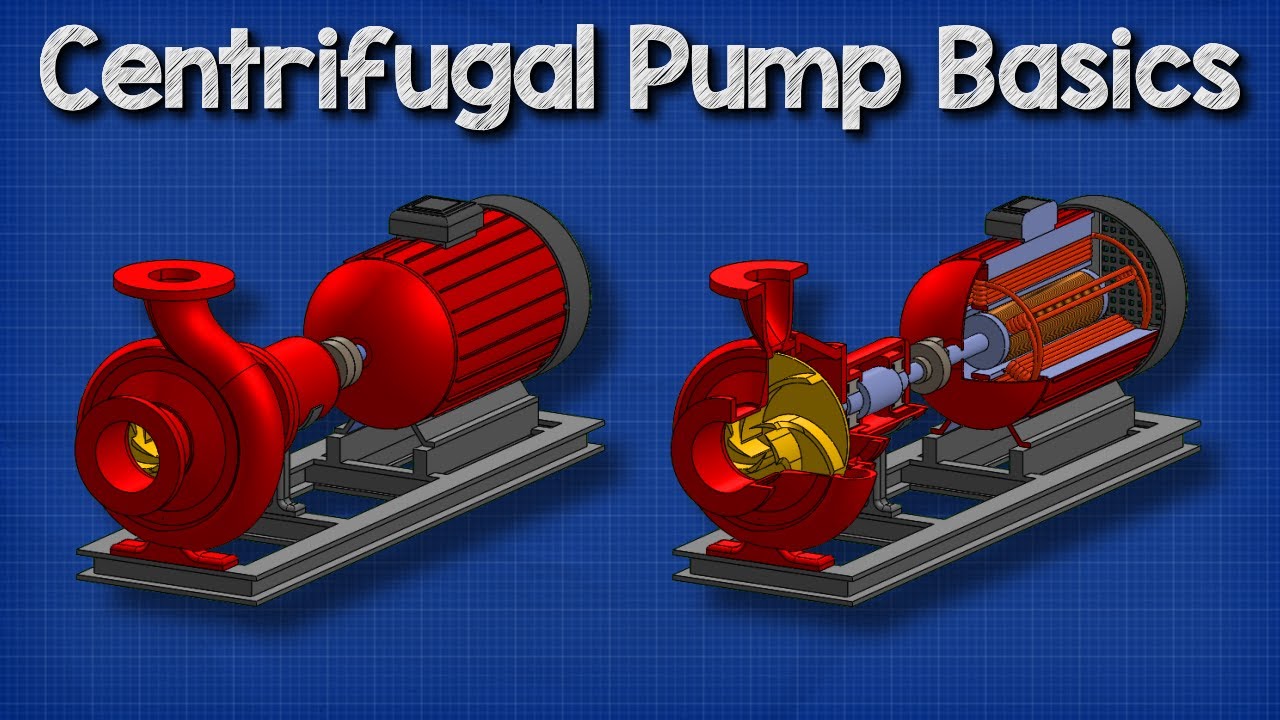

TLDRThis YouTube video script offers an in-depth look at the technical evaluation of centrifugal pumps, focusing on API Standard 610. It covers essential aspects such as pump design life, operating conditions, and mechanical data sheets. The script guides viewers through the process of evaluating pump performance, ensuring a minimum service life of 20 years and uninterrupted operation. It also discusses the importance of checking the margin of safety for cavitation, pump shut-off head, and specific speed to ensure optimal pump performance and prevent issues like high vibration and cavitation.

Takeaways

- 📘 The video discusses the technical evaluation of centrifugal pumps, focusing on mechanical data sheets in accordance with API Standard 610.

- 🔍 API Standard 610 is the key guideline for the basic design of centrifugal pumps used in the petroleum, petrochemical, and natural gas industry.

- 🛠️ The video emphasizes the importance of being familiar with other applicable standards such as API 674, 675, 676, 681, and 685 for different types of pumps.

- 🔬 It is mandatory for centrifugal pumps covered by API 610 to be designed and constructed for a minimum service life of 20 years, excluding normal wear parts.

- ⏱️ The equipment should have at least three years of uninterrupted operation, as per API 610 standards.

- 🛒 Purchasers are responsible for specifying operating conditions, liquid properties, site conditions, and utility conditions for the centrifugal pump.

- 📋 The purchaser represents the owner or agent issuing orders and specifications to the vendor, and must ensure all necessary information is detailed in the process data sheets.

- 💡 The video explains how to check if a pump is capable of at least a 5% head increase at rated conditions, which is a requirement as per API 610.

- 🌡️ The margin of safety for cavitation is crucial and should be greater than 0.6 meters, comparing the system characteristics (MPSHA) with the pump characteristics (MPSHR).

- 📊 The concept of shut-off head is introduced, which should not exceed the downstream design pressure to prevent operational issues.

- 🔄 The pump's function specific speed is an important consideration for optimal performance, with a commonly accepted limit of 11,000 US units to avoid high vibration.

Q & A

What is the main focus of the video script?

-The main focus of the video script is the technical evaluation of centrifugal pump mechanical data sheets with respect to API Standard 610, which governs the basic design of centrifugal pumps used in the petroleum, petrochemical, and natural gas industry.

What are the other applicable standards mentioned in the script for pump packages?

-The other applicable standards mentioned are API Standard 674 for positive displacement pumps (specifically reciprocating pumps), API Standard 675 for control volume pumps, API Standard 676 for rotary pumps, API Standard 681 for liquid ring vacuum pumps, and API Standard 685 for centrifugal pumps.

What is the minimum service life expected for a centrifugal pump designed according to API 610?

-According to API 610, a centrifugal pump should be designed and constructed for a minimum service life of 20 years, excluding normal wear parts as identified in Table 20 of the standard.

What is the significance of the purchaser specifying the operating conditions for a centrifugal pump?

-The purchaser specifying the operating conditions is significant because it ensures that the pump is designed and supplied to meet the specific requirements of the application, including liquid properties, site conditions, and utility conditions.

What is the importance of the pump being capable of at least a 5% head increase at rated conditions as per API 610?

-The ability to achieve at least a 5% head increase at rated conditions ensures that the pump has the flexibility to operate under varying conditions without compromising performance, which is a requirement for pumps designed according to API 610.

How is the 5% head increase checked on a pump curve?

-The 5% head increase is checked by calculating the ratio of the head at maximum impeller diameter to the head at rated impeller diameter minus one, and then multiplying by 100 to get a percentage. This value should be greater than 5% to meet the API 610 requirement.

Why is the Net Positive Suction Head Required (NPSHR) specified by the vendor important on the mechanical data sheet?

-The NPSHR is important because it represents the pump characteristics and is used to prevent cavitation. It must be specified by the vendor on the mechanical data sheet based on water at a temperature of less than 55 degrees Celsius at the rated flow and rated speed.

What is the significance of checking the margin of safety for cavitation?

-Checking the margin of safety for cavitation is crucial to ensure that the pump operates without cavitation, which can cause damage and reduced efficiency. The margin is the difference between the Net Positive Suction Head Available (NPSHA) and the NPSHR, and it should be greater than a specified minimum, often 0.6 meters or more.

What is the purpose of calculating the pump's shutoff head during the technical evaluation?

-Calculating the pump's shutoff head helps to determine the practical feasibility of the pump and to ensure that it will not exceed the downstream design pressure, which could lead to operational issues or equipment damage.

Why is the pump function specific speed important in the technical evaluation?

-The pump function specific speed is important as it is an indicator of the pump's performance characteristics. A high specific speed can suggest susceptibility to high vibration, and it is generally recommended to keep the specific speed below certain limits, such as 11,000 US units, for optimal pump performance.

What does the preferred operating region of a pump represent according to API 610?

-The preferred operating region, as stated in API 610, represents the range of flow rates where the pump operates most efficiently and reliably, typically between 70% to 120% of the pump's best efficiency flow rate.

Why is it necessary to ensure that the rated flow is within 80% to 110% of the best efficiency flow rate?

-Ensuring that the rated flow is within this range guarantees that the pump operates within its most efficient and reliable performance region, which is a requirement for pumps designed as per API 610.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

Bombas Centrífugas - Tipos

Centrifugal Pump Basics I Definition I Working I Velocity Triangle I Work Done I Head I Efficiency

Pump Performance Curve Explained | Master the Pump Curve for Optimal Results | Pump Curve

About Atkin Chambers for Pupillage Applicants

Lifebuoys. What You Need To Know?

5.0 / 5 (0 votes)