Episode 1 - PENGUJIAN TAN DELTA BUSHING (Knowledge Sharing)

Summary

TLDRThis video focuses on the Tan Delta testing method used to evaluate insulation quality in electrical equipment like transformers. It explains how insulation degradation occurs due to factors such as humidity, mechanical damage, and electrical stresses. Tan Delta testing measures both capacitive and resistive components, with increasing resistive current indicating worsening insulation. The video highlights the importance of regular testing, typically every two years, and compares results to established standards. It also discusses procedures for assessing insulation points, such as C1 and C2 configurations, to ensure reliable and safe equipment operation.

Takeaways

- 😀 The video discusses the concept of insulation degradation and the methods used to test it, including Delta testing.

- 😀 Delta testing is essential for identifying insulation degradation, which can be caused by factors such as polarization effects, humidity, mechanical damage, and corrosion.

- 😀 Insulation degradation leads to resistive currents that can be detected through Delta testing, helping to assess the quality of equipment insulation.

- 😀 The video provides an example of equipment degradation using a transformer and its oil insulation, where contamination causes insulation deterioration.

- 😀 As insulation degrades, the resistive current (Ir) increases, and the Tan Delta value also grows, indicating worsening insulation.

- 😀 Tan Delta testing is crucial for determining insulation quality, and it should be conducted regularly, typically every two years or under conditional circumstances.

- 😀 Key parameters to monitor during Tan Delta testing include capacitance and Tan Delta, which can be used to assess insulation health.

- 😀 The formula for capacitance (C) is calculated using the permittivity of the material (ε), the area (A), and the distance between layers (d), while Tan Delta is the ratio of resistive current to capacitive current.

- 😀 Tan Delta testing can detect issues such as insulation aging, water content, electrode contact problems, and partial discharge.

- 😀 According to standard guidelines (SG-2520), Tan Delta testing should be done every two years, and values exceeding certain thresholds (e.g., 0.7%) indicate the need for insulation replacement.

Q & A

What is the main purpose of the Tan Delta test?

-The main purpose of the Tan Delta test is to assess the quality of insulation in electrical equipment, identifying degradation due to factors such as polarization effects, mechanical damage, humidity, corrosion, and more.

What are the causes of insulation degradation in electrical equipment?

-Insulation degradation can be caused by polarization effects, such as heat, humidity, mechanical damage, chemical corrosion, corona discharge, voltage surges, and other factors.

How does insulation degradation affect electrical systems?

-Insulation degradation leads to the formation of resistive currents that pass through the insulation, which can be detected by the Tan Delta and Power Factor tests.

What is the significance of the Ir value in Tan Delta testing?

-The Ir value represents the resistive current in the insulation, and an increase in Ir indicates worsening insulation. As insulation degrades, the Ir value and the Tan Delta measurement increase.

Why is regular Tan Delta testing necessary for electrical equipment?

-Regular Tan Delta testing is necessary to monitor the condition of insulation and detect any degradation that could lead to equipment failure. It is typically conducted annually to ensure the safety and reliability of electrical systems.

What parameters are observed during Tan Delta testing?

-The primary parameters observed during Tan Delta testing are capacitance and Tan Delta values, which provide insights into the quality of the insulation.

What is the formula for capacitance in Tan Delta testing?

-The formula for capacitance (C) is: C = ε * A / d, where ε is the permittivity of the material, A is the area, and d is the distance between layers.

How does Tan Delta help in identifying insulation problems like partial discharge?

-Tan Delta testing can help detect issues such as insulation aging, degradation, high moisture content, poor electrode contact, installation defects, and partial discharge within the insulation.

What are the standards for Tan Delta values according to SG-2520?

-According to SG-2520, Tan Delta testing should be performed every two years or in conditional situations. If the Tan Delta value exceeds 1% for specific insulation types, equipment may need to be replaced.

What is the role of Basing in Tan Delta testing, and how is it structured?

-Basing refers to the insulation layer in transformers and other equipment. It consists of layers such as the center conductor, tab electrodes, and layers that provide electrical insulation, and the condition of these layers is monitored during Tan Delta testing.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

#5 K3 Listrik - Pengukuran Tahanan Isolasi

Generation of High A.C. Voltages Cascaded Transformer - High Voltage Engineering

20 Jenis peralatan distribusi listrik

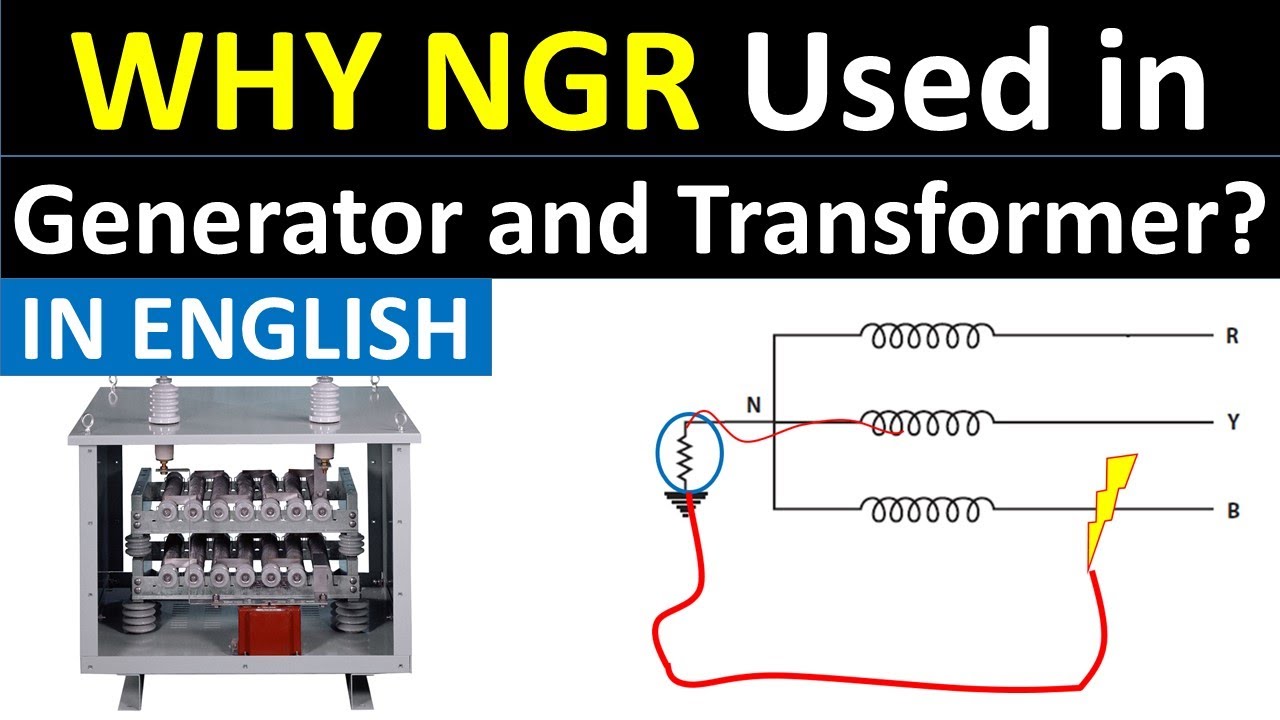

[English] Why NGR? : Neutral Grounding resistor Part-1

Cegah Kebakaran Rumah Dengan Megger Kabel

Potential Transformer (PT) | control Transformer; use

5.0 / 5 (0 votes)