How Does an Electric Dryer Work? — Appliance Repair Tips

Summary

TLDRThis video explains how dryers work through the combined action of airflow, heat, and drum rotation. It details the process of air intake, heating, and circulation inside the drum to dry clothes efficiently. Proper airflow and ventilation are emphasized as crucial to the dryer's performance, and potential problems like overheating, tripped fuses, and airflow blockages are discussed. The video also covers maintenance tips, such as cleaning the lint screen and vent, and highlights common issues like worn drum supports and broken belts, with solutions provided through Repair Clinic’s resources.

Takeaways

- 🌀 All dryers function using airflow, heat, and drum rotation, which work together to dry clothes efficiently.

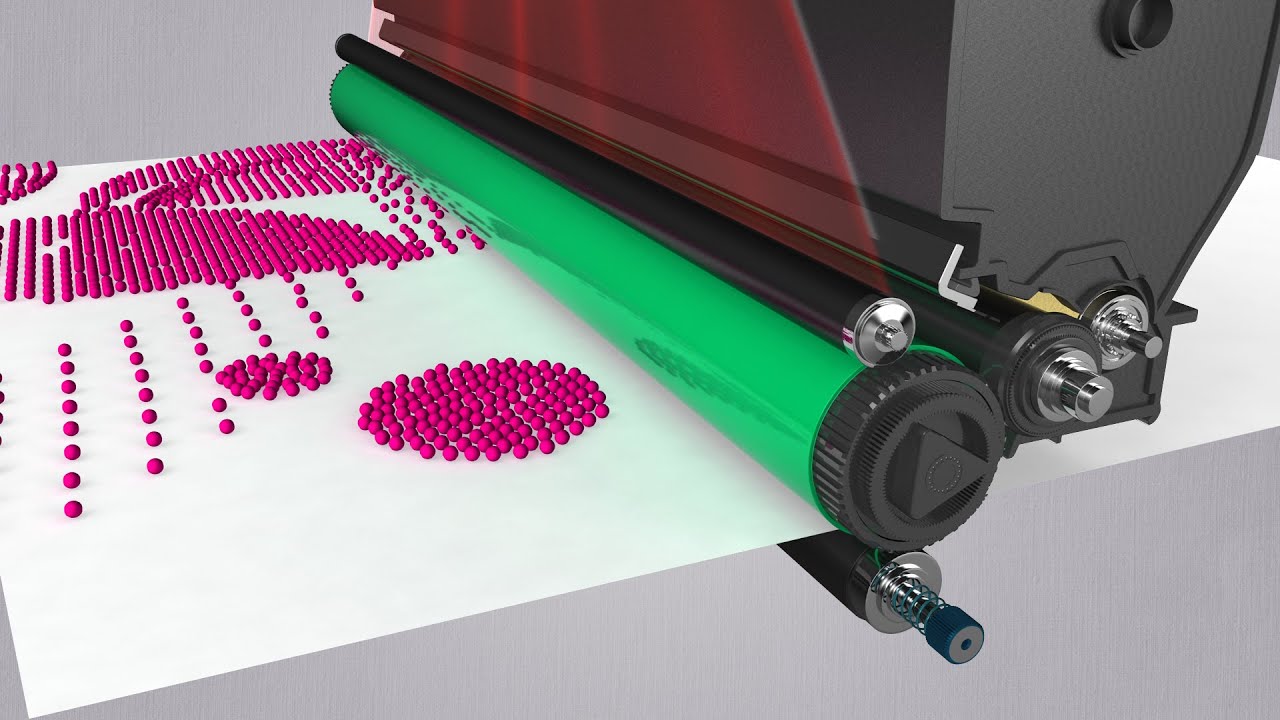

- 💨 Dryers use a blower wheel to draw air from the front or rear of the appliance, heating the air and circulating it through the clothes as the drum rotates.

- 🔥 Electric dryers heat the air using a heating element, and airflow is critical to proper operation.

- 🚪 Proper airflow requires the dryer to be placed in an open, well-ventilated area, with enough space behind it to allow air to flow freely.

- ⚠️ Poor airflow can cause the high-limit thermostat to overheat, shutting off the heating element and lengthening drying time.

- 🔌 Two types of venting material can be used: rigid venting (effective up to 40 ft) and semi-rigid venting (up to 20 ft), with bends reducing efficiency.

- 🔄 The heating element activates when it receives 240 volts of alternating current through two voltage legs, and thermostats regulate the heating process.

- 🧰 If the dryer isn’t heating properly, common causes include a malfunctioning thermal fuse, heating element, high-limit thermostat, or thermal cut-off fuse.

- 🧹 Regular cleaning of the lint screen and exhaust vent is crucial for maintaining airflow and preventing fire hazards.

- 🔧 Repair Clinic offers resources like part testing, disassembly, and replacement guides to help with troubleshooting and fixing dryer issues.

Q & A

What are the three main factors that contribute to the operation of a dryer?

-The three main factors are airflow, heat, and drum rotation.

How does airflow impact the dryer’s performance?

-Airflow helps circulate the heated air through the clothes. Poor airflow can prevent proper drying, cause the heating element to overheat, and damage thermostats or fuses.

What is the role of the blower wheel in a dryer?

-The blower wheel draws air into the dryer from either the front or rear, which is then heated and circulated through the clothes during the drying process.

Why is it important to ensure that the dryer has sufficient space around it?

-Sufficient space is needed to allow proper airflow. The back of the dryer should be several inches away from the wall to prevent overheating and poor air circulation.

What can happen if the airflow is restricted due to a clogged vent or lint buildup?

-Restricted airflow can cause the dryer to overheat, leading to potential damage to the high-limit thermostat or thermal fuses. This may result in the dryer not heating or not running at all.

How often should the lint screen be cleaned, and why is it important?

-The lint screen should be cleaned after every load to maintain proper airflow, reduce the risk of overheating, and ensure the dryer operates efficiently.

What types of venting materials are recommended for dryers, and what are their length limits?

-Rigid venting is recommended and is efficient up to 40 feet, while semi-rigid venting is efficient up to 20 feet. Bends in the venting reduce these length limits.

What should be done if the dryer is not heating properly?

-You should test components like the heating element, thermal fuse, high-limit thermostat, and thermal cutoff fuse individually to determine if any of them are faulty.

What is the function of the cycling thermostat in a dryer?

-The cycling thermostat monitors the air temperature inside the dryer and switches off the heating element when the desired temperature is reached.

What might cause the dryer drum to stop rotating even though the motor is running?

-The drive belt may have broken, or one of the support components such as rollers, glides, or pulleys could have failed, causing the drum to stop rotating.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тариф5.0 / 5 (0 votes)