Frederick Taylor | Scientific Management Explained

Summary

TLDRThis video explores Frederick Winslow Taylor's scientific management theory, highlighting its principles like task specialization and time-motion studies to boost efficiency. It examines the theory's application in McDonald's, emphasizing standardization, consistency, and efficiency. The video also discusses the advantages of increased productivity and cost reduction, as well as the downsides of job monotony and dehumanization, ultimately presenting a balanced view of Taylorism's impact on modern business practices.

Takeaways

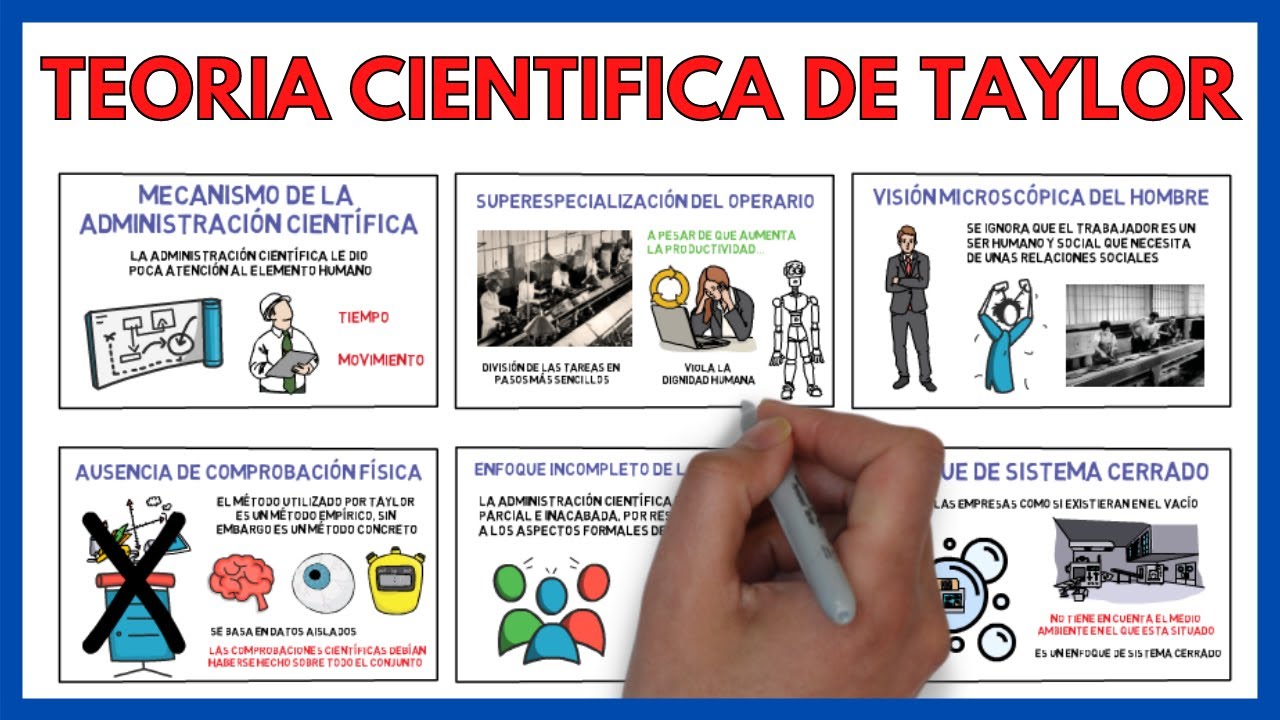

- 🔧 Frederick Winslow Taylor developed the scientific management theory, also known as Taylorism, which aimed to increase efficiency and productivity through scientific methods.

- 💡 Taylor believed that the main motivator for employees was pay and that workers should be given one task to master.

- ⏱️ Time and motion studies were introduced to break down tasks and identify the quickest way to complete them, leading to more efficient workflows.

- 🛠️ Jobs were simplified into smaller, manageable tasks, allowing for increased efficiency without requiring highly skilled workers.

- 💰 Taylor advocated for piece rate pay, where employees are rewarded based on their productivity, to motivate workers and maximize profits.

- 🍔 McDonald's is a prime example of a business that has successfully implemented Taylor's scientific management principles, starting from its inception.

- 🔄 The 'Speedy System' at McDonald's is a direct application of Taylorism, with tasks broken down and standardized to optimize efficiency.

- 🌐 Standardization is a key aspect of McDonald's success, with every franchise adhering to a uniform layout and procedures, reflecting Taylor's emphasis on consistency.

- 🔄 Consistency in product quality across all McDonald's locations is achieved through strict adherence to set procedures, a principle derived from Taylorism.

- 📉 While Taylorism increased productivity and profits, it also led to monotonous jobs, reduced autonomy, and a dehumanizing work environment for employees.

- 📈 The scientific management approach can lead to increased unemployment as businesses require fewer workers due to increased efficiency and output.

Q & A

Who was Frederick Winslow Taylor and what is his main contribution to management theory?

-Frederick Winslow Taylor was an American engineer and management consultant who is best known for developing the scientific management theory, also known as Taylorism.

What are the core beliefs of Taylor's scientific management theory?

-Taylor's theory is based on the belief that the main motivator for employees is pay and that science can be used to increase efficiency and productivity. He advocated for workers to be given one task to master and emphasized that systems, rather than individuals, should be the priority for a productive workforce.

What is the concept of 'one best way' in Taylor's theory?

-The 'one best way' concept in Taylor's theory suggests that businesses should use scientific methods to identify the most efficient way to perform a task and then standardize that method across the entire workforce.

How did Taylor propose to increase worker productivity?

-Taylor proposed increasing worker productivity by breaking down jobs into smaller, more manageable tasks, conducting time and motion studies to find the quickest way to complete tasks, and then motivating employees through pay incentives based on their productivity.

What is the piece rate pay system mentioned in the script?

-Piece rate pay is a system where employees are paid based on the number of items they produce. It was a key part of Taylor's theory to motivate workers to be more productive by directly linking their pay to their output.

How did McDonald's implement Taylor's scientific management principles?

-McDonald's implemented Taylor's principles by developing the 'Speedy System,' which involved meticulous design of kitchens and workspaces for efficiency, breaking down tasks into small jobs, and standardizing procedures across all franchises to ensure consistency and quality.

What is the role of standardization in McDonald's success according to the script?

-Standardization plays a crucial role in McDonald's success by ensuring that every franchise has a consistent look, layout, and quality of food, which helps in maintaining the brand's identity and customer expectations.

How does the scientific management approach affect the skill requirement of jobs at McDonald's?

-The scientific management approach has turned complex tasks, such as being a chef, into lower-skill processes by breaking them down into simple, repetitive tasks. This increases efficiency but may reduce the need for highly skilled workers.

What are the advantages and disadvantages of Taylor's scientific management theory as discussed in the script?

-The advantages include increased productivity, cost reduction through fewer employees, consistent product quality, and potential for higher pay for productive workers. Disadvantages include monotonous jobs, lack of worker autonomy, potential for increased unemployment due to increased productivity, and a dehumanizing work environment.

How does Taylor's theory create a 'survival of the fittest' environment in the workplace?

-Taylor's theory creates a 'survival of the fittest' environment by rewarding high productivity with higher pay and potentially firing or pressuring less productive workers to leave, making employee worth solely based on productivity.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Taylorism ABC World Report

Estudos Organizacionais - Abordagem Científica da Administração - Introdução às Teorias... (LIBRAS)

TEORIA CIENTIFICA de la ADMINISTRACION de FREDERICK WINSLOW TAYLOR ✅ | Economía de la Empresa 141#

Padres de la administración: Frederick Taylor

Frederick W Taylor :The Father of Scientific Management

A level Business Revision - Taylorism, Scientific Management & Motivation

5.0 / 5 (0 votes)