What is Process Control - A Galco TV Tech Tip | Galco

Summary

TLDRKatie from Galco TV introduces process control, essential for maintaining variables like temperature and pressure in industrial settings. It ensures product quality, automates processes, and reduces the need for personnel. Process control operates within a closed-loop system, using feedback from sensors to adjust deviations. Programmable Logic Controllers (PLCs) are highlighted as key in controlling machines with multiple discrete devices, crucial for automation processes. For inquiries, viewers are directed to Galco's technical help forum or website.

Takeaways

- 🔬 Process control is essential for maintaining variables like temperature, pressure, flow, or level within a desired range in industrial settings.

- 📈 Precise control of process variables is critical as it improves product quality, enables automation, and reduces the need for personnel to monitor complex processes.

- 🔄 Process control is part of a closed-loop system where a process variable is measured against a setpoint, and corrective actions are taken for any deviation.

- 🔙 Closed-loop control is feedback-dependent, using sensors to monitor process variables and providing feedback to the final control element to correct deviations.

- 🛠️ Controllers play a significant role in reducing variability, increasing efficiency, and ensuring safety in industrial processes.

- 🔎 Equipment that requires constant monitoring of a process variable can benefit from a process controller.

- 🔧 Process controllers offer multiple types of control suited to different applications and process variables.

- 🤖 Programmable Logic Controllers (PLCs) are often used in process control systems for controlling machines with several discrete devices.

- 🔄 PLCs are ideal for automation processes involving material handling, state machines, sequencing, and status reports.

- ❓ For questions or further information, viewers are directed to Galco's technical help forum or website.

- 🌐 The technical help forum can be found at forum.galco.com, and more information is available on galco.com.

Q & A

What is process control?

-Process control refers to the methods used to maintain the output of process variables such as temperature, pressure, flow, or level within a desired range.

Why is precise control of process variables critical in industrial settings?

-Precise control of process variables is critical as it improves the quality of products, enables automation, and requires fewer personnel to monitor and control complex processes.

How does a closed-loop system work in process control?

-A closed-loop system in process control measures a process variable, compares it to a setpoint, and takes action to correct any deviation from the setpoint.

What is the role of feedback in closed-loop control systems?

-Feedback in closed-loop control systems is dependent on receiving information from sensors monitoring the process variable and providing feedback to the final control element to correct deviations from the setpoint.

How do controllers help in process control?

-Controllers assist in reducing variability, increasing efficiency, and ensuring safety by monitoring and correcting process variables.

What is a process controller and how does it benefit equipment that requires constant monitoring?

-A process controller is a device that benefits equipment needing constant monitoring of a process variable by providing precise control and automation, thereby reducing the need for manual oversight.

What types of control can process controllers provide, and for what applications are they suited?

-Process controllers can provide multiple types of control suited to different applications and process variables, tailored to specific industrial needs.

What are the primary devices used in a process control system?

-The primary devices used in a process control system are Programmable Logic Controllers, or PLCs.

Why are PLCs often the best option for controlling machines with several discrete devices?

-PLCs are often the best option for controlling machines with several discrete devices like motor starters and limit switches because they can handle complex automation processes such as material handling, state machines sequencing, and status reports.

How can one get more information or ask questions about process control?

-For more information or to ask questions about process control, one can visit the technical help forum at forum.galco.com or the website galco.com.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

What Is Industrial Instrumentation? Start Here! 💡 Ep1

1. Introduction - Process Control Instrumentation -

Process control loop Basics - Instrumentation technician Course - Lesson 1

Regelkringen in productie- en procesinstallaties

AASTU, Chemical Engineering Department, Process Control Lab.#laboratory #engineering #process

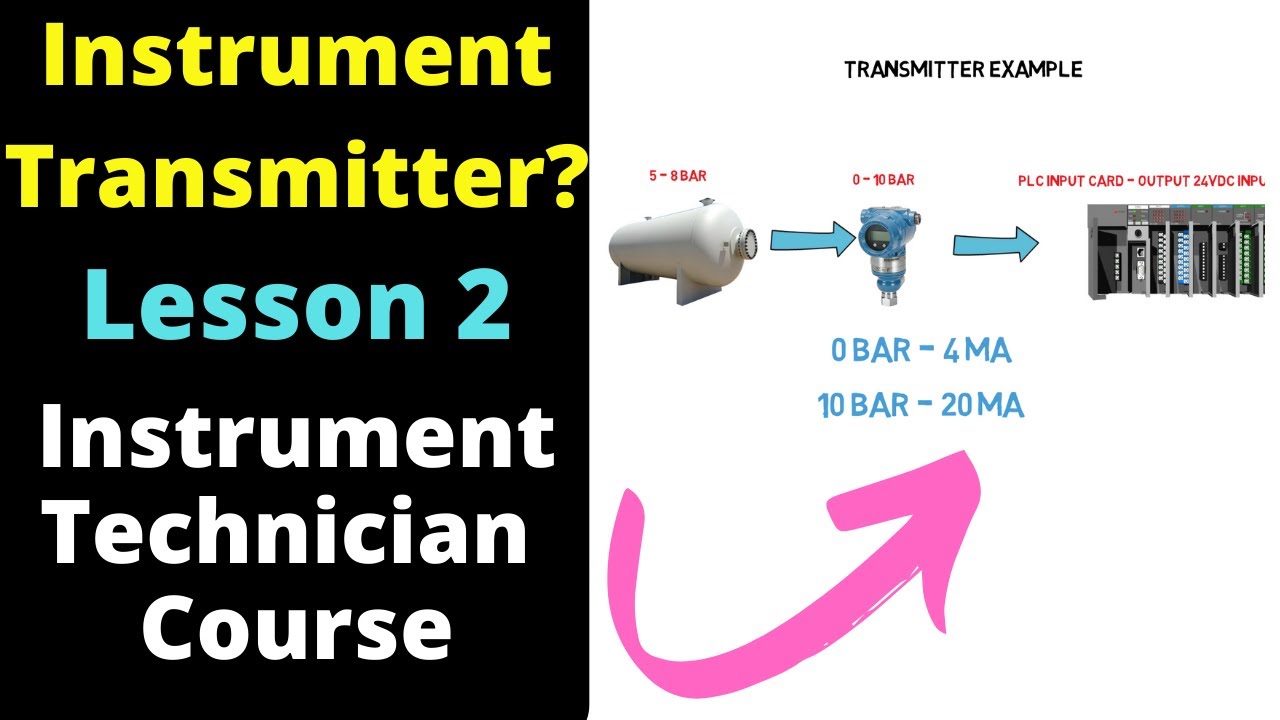

What is a Transmitter -Instrumentation Technician Course - Lesson 2

5.0 / 5 (0 votes)