TWO SIMPLE AND RELIABLE BOTTLE CUTTERS!!!!!!

Summary

TLDRIn this tutorial, the host demonstrates how to craft two reliable, yet simple bottle openers using 20mm wide and 140mm long plywood strips. The process involves breaking a 18mm office knife blade, marking spots for screws, and creating notches for a tape measure. Precision cutting is emphasized, with the guide being bent to prevent injury. The second opener is assembled with two nuts and M6 bolts, highlighting a hands-free operation. Both openers are tested for smooth and even cutting, proving their effectiveness with just a single blade.

Takeaways

- 🛠️ The video demonstrates how to make two types of simple yet reliable bottle openers using wooden planks.

- 📏 The dimensions of the wooden planks used are 20 mm in width and 140 mm in length.

- 🔪 A utility knife blade of 18 mm is used for the cutting mechanism.

- 📐 Marking is done for the placement of screws and cutting slots at specific distances from the blade.

- ✂️ The slots are made for inserting a tape measure, with different widths marked for different cutting depths.

- 🔩 Screws are used for attaching the guiding mechanism, ensuring the opener's functionality.

- 🗡️ The knife blade is broken to create a sharp edge for cutting.

- 🔨 A metal awl is used for making holes to prevent wider cuts than the slots, which would affect the opener's precision.

- 🔧 The guiding mechanism is crucial for the opener's operation and includes a safety tip to prevent injury.

- 🔩 The second bottle opener is assembled with two nuts and bolts, allowing for easy adjustment without tools.

- 🎉 The video concludes with the successful creation of two functional bottle openers made from a single blade, suggesting viewers subscribe and like the video if they find it useful.

Q & A

What is the main topic of the video?

-The video is about demonstrating how to make two types of simple yet reliable bottle openers using wooden planks.

What materials are required to make the bottle openers as shown in the video?

-The materials required include wooden planks of 20 mm width, 40 mm thickness, and 140 mm length, one utility knife blade of 18 mm, and screws.

How many screws are needed for the second bottle opener according to the video?

-The second bottle opener requires 20 screws and two M6 bolts of arbitrary length.

What is the purpose of making notches on the wooden plank?

-The notches are made to accommodate the screws and to guide the utility knife blade for cutting the wood in a straight line.

What is the significance of the diagonal positioning of the guide on the bottle opener?

-The diagonal positioning of the guide ensures that the bottle opener cuts the bottle cap smoothly without slipping.

How does the video suggest attaching the utility knife blade to the wooden plank?

-The video suggests attaching the utility knife blade approximately 1.5 centimeters from the start and marking the spots for screws slightly further away from the blade.

What is the purpose of the grooves for the tape mentioned in the video?

-The grooves for the tape are used to guide the cutting process, ensuring a straight and even cut on the bottle caps.

How many different groove sizes are demonstrated in the video?

-The video demonstrates grooves for 3 mm, 5 mm, 7 mm, and 10 mm bottle caps.

What is the recommended method for cutting the wood according to the video?

-The recommended method is to use the back of the knife, hitting the metal part, to ensure the cuts are narrower than the pre-made notches for a better fit.

What is the final step shown in the video for assembling the second bottle opener?

-The final step is to insert the blade and secure it by tightening the screws and bolts, ensuring the bottle opener is firmly assembled.

What is the viewer's call to action at the end of the video?

-The viewer is encouraged to like the video, subscribe to the channel, and share the video if they found it useful.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

CARA MEMBUAT TEMPAT PENSIL DARI BOTOL DAN KORAN/MAJALAH BEKAS

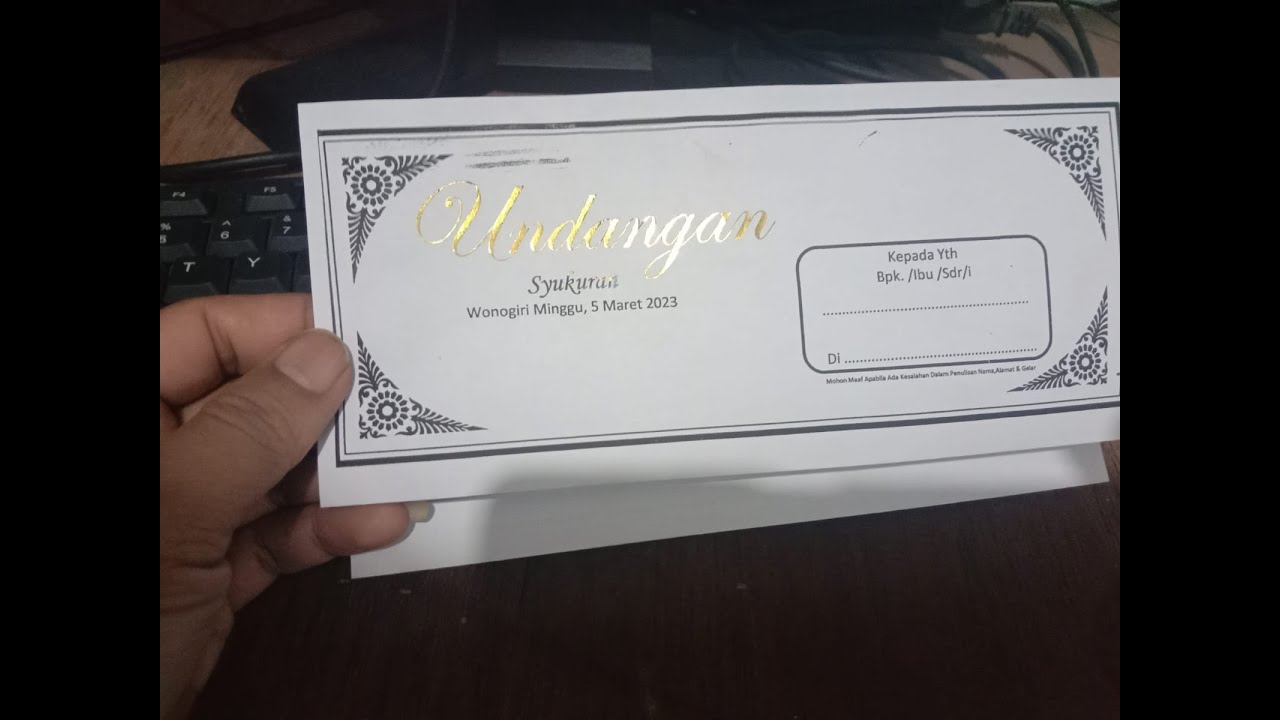

cara membuat undangan tasyakuran|microsoft word

Origami Lucky Star - How to fold

Cara Membuat Mainan Dari Botol Bekas !! Ide Kreatif, Bottle Craft

How to Make a Table Decoration Flower Vase - Craft from Ice Cream Sticks

Tempat Pensil Dari Botol Bekas / Contoh Kegiatan P5 Kurikulum Mereka

5.0 / 5 (0 votes)