Forklift-Free Focus for Terex with MasterMover Electric Tugs

Summary

TLDRTX is a global company committed to improving safety and efficiency in their operations. By implementing safety road maps, such as the Material Movement Road Map, TX has significantly reduced forklift truck usage and enhanced flexibility in production. The introduction of the electric tug, specifically the PS3000 Plus, has improved operational efficiency and safety by allowing operators to move large loads with ease and better visibility. The partnership with Master Mover has been instrumental in reducing downtime and increasing productivity, making it a highly recommended solution for heavy industry manufacturers.

Takeaways

- 😀 TX is a global company with a strong portfolio of specialized machinery brands and a vision to improve team members' lives while maintaining safety as a top priority.

- 😀 TX aims to be the safest and best place to work in their industry, with a focus on zero harm and a robust safety culture.

- 😀 One of TX's key safety initiatives is the Material Movement Roadmap, which focuses on reducing forklift truck movement and segregating these from team members.

- 😀 TX is exploring ways to completely remove forklift trucks from production areas, particularly on the shop floor.

- 😀 The company has made significant improvements in flexibility by adopting the electric tug system, enhancing their production process.

- 😀 Previously, bringing in products and moving large loads required stopping production, but the new system has eliminated downtime, improving efficiency.

- 😀 The electric tug system allows for just-in-time product movement, reducing unnecessary waiting and contributing to greater productivity.

- 😀 The PS3000 Plus remote control feature gives operators unrivaled visibility while moving large loads, enabling them to assess situations from multiple angles.

- 😀 Operators can now move large loads while walking around them, minimizing blind spots and enhancing safety compared to traditional forklift operations.

- 😀 The Master Mover solution has greatly improved safety and efficiency in operations, with a fantastic relationship between TX and Master Mover.

- 😀 TX highly recommends Master Mover's electric tug solutions for other heavy industry manufacturers looking to improve safety and operational efficiency.

Q & A

What is the primary goal of TX's safety culture?

-TX's primary goal is to improve the lives of its team members while striving to be the safest and best place to work in the industry.

What is the material movement roadmap, and why is it important for TX?

-The material movement roadmap is a key part of TX’s safety culture, focusing on reducing forklift truck movement and segregating them from team members. It aims to improve safety and efficiency within production areas.

How does TX plan to reduce the use of forklift trucks in production areas?

-TX aims to completely remove forklift trucks from production areas by utilizing more efficient and safer alternatives, such as the electric tug.

What was the main issue with using forklifts before adopting electric tugs?

-Before using electric tugs, TX had to stop production to bring in forklifts and reverse them into the sheds, leading to wasted time and reduced production efficiency.

What is the benefit of using the electric tug for TX's operations?

-The electric tug has drastically improved flexibility by allowing TX to move products just in time and without having to wait, significantly reducing downtime and increasing efficiency.

How does the remote control feature of the PS3000+ enhance safety during operations?

-The remote control feature provides the operator with unparalleled visibility while moving large loads, allowing them to walk around and assess the situation from all angles, reducing blind spots and improving overall safety.

What is the advantage of walking around while controlling the electric tug?

-Walking around while controlling the electric tug enables the operator to be in full control and assess any potential risks or obstacles, ensuring safer operations compared to being confined to a forklift.

What improvements has TX seen in terms of efficiency and downtime since adopting the electric tug?

-TX has seen significant improvements in flexibility and reduced downtime, as they no longer need to stop production to move large items, resulting in smoother and more efficient operations.

What is TX's relationship with Master Mover, and how has it benefited them?

-TX has a strong relationship with Master Mover, which has provided electric tug solutions to improve safety and operational efficiency. This partnership is expected to grow stronger and continue driving positive changes for TX.

Why does TX recommend Master Mover's electric tug solutions to other heavy industry manufacturers?

-TX recommends Master Mover's electric tug solutions because they have proven to drive safer and more efficient operations, simplifying processes and reducing the risks associated with traditional forklifts.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

Know what a Medical Virtual Assistant from the Global Medical VA’s Managing Director, George Cortes

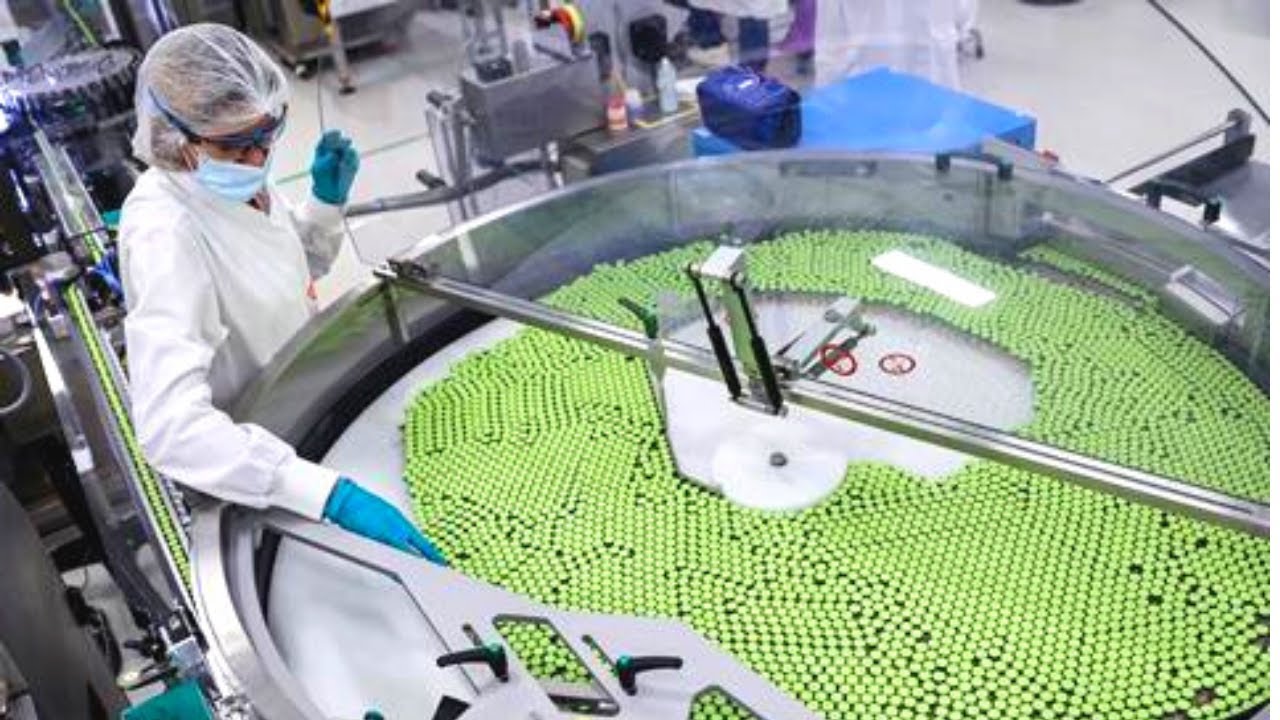

Inside AstraZeneca Modern Pharmaceutical Production Plant | Modern Factory

Case Study: BioBridge Global Connects Digital Manufacturing and Quality Management

Dave Clark unpacks the current state of supply chain and AI at Manifest 2025

Carpentry Contractors Prefab Wall & Floor Panel Framing

Framatome’s industrial Computational Fluid Dynamics (CFD) solution

5.0 / 5 (0 votes)