Making Phenol by decarboxylation of salicylic acid

Summary

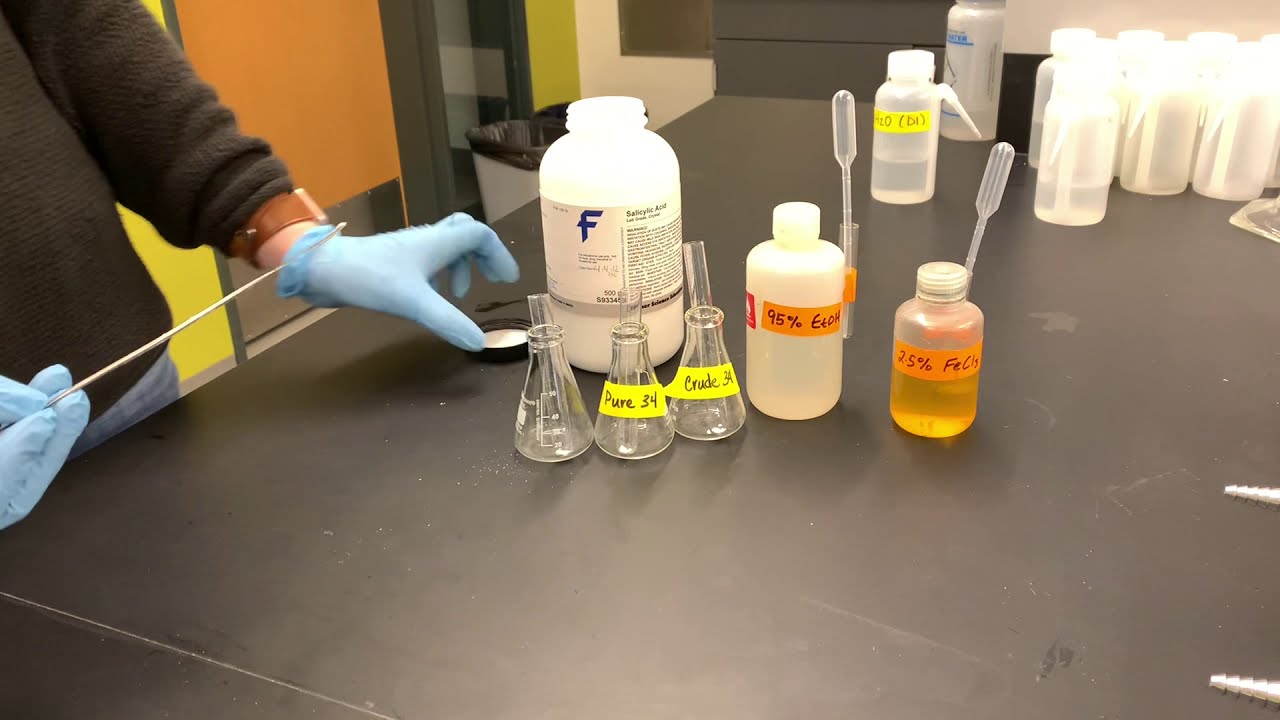

TLDRIn this video, the process of synthesizing phenol from salicylic acid is demonstrated. The experiment begins by heating salicylic acid in a distillation setup, where it undergoes a decarboxylation reaction to break down into phenol and carbon dioxide. The video showcases the steps of heating, distillation, and cooling, while addressing safety precautions due to the toxic nature of phenol. After the first distillation, the crude phenol is purified through a second round of distillation. The final yield is 49.5 grams of pure phenol, with 20.2 grams of dirty phenol remaining. The experiment emphasizes the importance of proper technique and safety in chemical processes.

Takeaways

- 😀 Phenol is toxic and can cause chemical burns, so safety precautions are essential during its preparation.

- 😀 Salicylic acid (138.1 grams) is the key chemical used to produce phenol through a decarboxylation reaction.

- 😀 The preparation process involves heating salicylic acid in a two-neck round bottom flask, which is part of a simple distillation setup.

- 😀 The reaction requires high heat, with the temperature needing to rise above 200°C for salicylic acid to break down into phenol and carbon dioxide.

- 😀 The distillation process faced cooling challenges as phenol solidifies at low temperatures; air cooling worked better than using warm water for condensation.

- 😀 Early stages of the process showed salicylic acid forming snowflake-like crystals at 76°C, which later melted to form phenol.

- 😀 The crude phenol produced initially contains impurities like water and residual salicylic acid, necessitating a second distillation.

- 😀 In the second distillation, phenol was collected between 170°C and 195°C, with anything below 170°C discarded as it was not pure phenol.

- 😀 The final product after distillation was clean phenol, which solidified after cooling and was stored safely in a specialized bottle.

- 😀 The yield of pure phenol was 49.5 grams (52.6%), with an additional 20.2 grams of impure or 'dirty' phenol collected for potential future use.

- 😀 The process was marked by a learning experience where the distillation was optimized by using air cooling and adjusting temperatures to avoid clogging.

Q & A

Why is phenol considered toxic and dangerous to handle?

-Phenol is toxic because it can cause chemical burns and has harmful effects on the skin, eyes, and respiratory system. It is corrosive and can lead to serious health issues if improperly handled.

What is salicylic acid, and where is it commonly used?

-Salicylic acid, also known as 2-hydroxybenzoic acid, is a chemical compound commonly used in acne creams due to its ability to exfoliate the skin. It is also used in the preparation of phenol in this script.

Why was a two-neck round bottom flask chosen for this experiment?

-A two-neck round bottom flask was chosen because the experiment required a more secure setup, allowing for better control over the process, such as using a heating mantle and connecting the condenser for distillation.

What was the purpose of using hot water in the condenser, and why did the experimenter later switch to air cooling?

-Hot water was initially used in the condenser to try to keep phenol in a liquid state since it has a melting point of 41°C. However, it didn't work well as the phenol kept solidifying. The experimenter switched to air cooling, which proved more effective in preventing the condenser from clogging.

What chemical reaction occurs when salicylic acid is heated to high temperatures?

-When salicylic acid is heated to around 200°C, it undergoes a decarboxylation reaction, breaking down into phenol and carbon dioxide.

What was the role of the heat gun in this experiment?

-The heat gun was used to carefully melt the phenol, allowing for a controlled transition from solid to liquid form. It was also used to observe the inside of the flask, creating a window to monitor the process.

Why is it important to carefully control the temperature during distillation?

-Temperature control is crucial to avoid overpressure in the apparatus and to ensure that the phenol distills at the right temperature range (170°C to 195°C). If the temperature rises too high, unsafe conditions like overpressure or loss of product could occur.

What are the main safety precautions followed in this experiment?

-Key safety precautions included wearing a respirator to protect from toxic fumes, using a heat gun to avoid direct contact with hot surfaces, and ensuring the apparatus was set up to prevent overpressure, which could cause hazardous glass breakage.

How was the purity of the phenol determined in this experiment?

-The purity of the phenol was determined by performing a second distillation, collecting phenol that boiled within the correct temperature range (170°C to 195°C). The resulting product was confirmed as clean phenol based on its appearance and boiling point.

What was the final yield of pure phenol in this experiment?

-The final yield of pure phenol was 49.5 grams, which represents 52.6% of the theoretical yield. In addition, 20.2 grams of dirty phenol were also collected.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード5.0 / 5 (0 votes)