Mechanical Troubleshooting

Summary

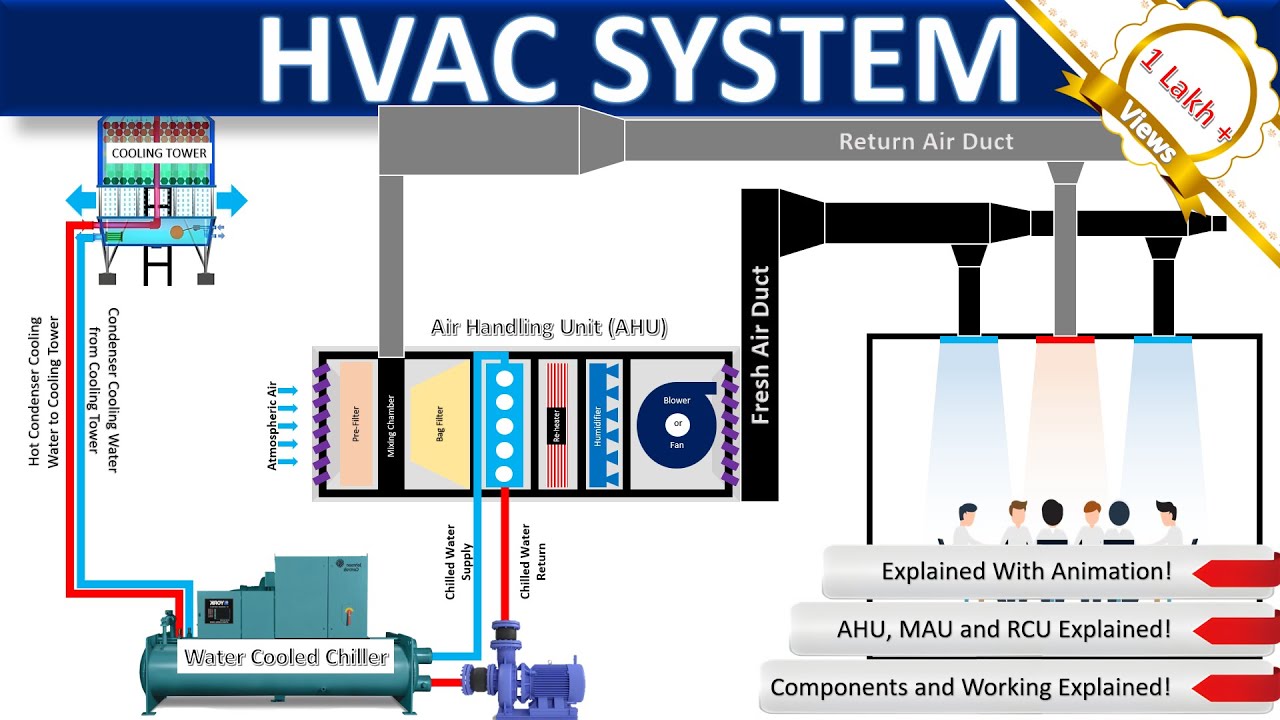

TLDRThis video series offers practical guidance for HVAC technicians, focusing on troubleshooting air conditioning systems. The script covers common issues such as restricted airflow, compressor failures, and refrigerant imbalances, with detailed procedures for diagnosing and resolving them. It emphasizes the importance of visual inspections, temperature and pressure checks, and preventive maintenance like cleaning coils and fans. Through real-world examples, the video highlights how technicians can avoid common mistakes and ensures that they develop the skills needed to handle complex HVAC problems. It also encourages continuous learning and staying updated with new technologies in the field.

Takeaways

- 😀 Identifying problems in air conditioning systems can involve both electrical and mechanical issues, and one can often lead to the other.

- 😀 Restricted air filters can cause refrigerant issues, like liquid refrigerant flowing back into the compressor, leading to oil dilution and motor failure.

- 😀 The technician should begin by inspecting the air filter and address any issues like severe blockages caused by nearby objects (e.g., a paper shredder).

- 😀 When a system freezes up, it’s essential to defrost it by running the indoor fan while the compressor is off to allow the system to thaw.

- 😀 Preventive maintenance measures, such as checking and cleaning pitted contactors and condenser fan motors, can prevent future issues and improve system reliability.

- 😀 Suction line temperatures and compressor condition can help identify refrigerant flow issues, such as the presence of liquid refrigerant in the suction line.

- 😀 Technicians should perform touch tests (e.g., feeling the suction line) before using gauges to check refrigerant levels, as improper gauge use can alter system charges.

- 😀 An overcharge of refrigerant is unlikely if the suction line is too cold, as liquid refrigerant would cause it to draw heat and feel much colder than vapor.

- 😀 Technicians need to approach refrigerant-related issues with caution, especially in systems with a critical refrigerant charge, to avoid making the problem worse during service.

- 😀 After completing repairs and maintenance, technicians should perform final system checks, including a leak check and testing to ensure proper refrigerant flow and compressor function.

Q & A

What is the primary focus of the video series?

-The primary focus of the video series is to provide students with practical service-oriented knowledge for troubleshooting and servicing air conditioning systems. It emphasizes real-life troubleshooting scenarios and service procedures.

What are the two main problem areas that air conditioning technicians face in the field?

-The two main problem areas are electrical and mechanical issues. These problems can sometimes overlap, with an electrical problem presenting as a mechanical issue or vice versa.

How can a restricted air filter affect an air conditioning system?

-A restricted air filter can prevent refrigerant from boiling off properly in the evaporator, causing liquid refrigerant to return to the compressor. This can lead to oil dilution in the compressor and may eventually cause a motor burn or compressor failure.

What was the technician's first step in diagnosing the issue in the service call example?

-The technician's first step was to check the indoor fan motor, which was running, and then inspect the air filter. He found that the air filter was severely restricted.

What caused the restricted air filter in the service call example?

-The restricted air filter was caused by its proximity to a paper shredder, which contributed to the accumulation of debris, restricting airflow.

Why is it important to perform preventive maintenance on components like contactors and the condenser fan motor?

-Preventive maintenance on components like contactors helps avoid problems such as the contacts welding shut, which can cause the compressor to run continuously and fail. Checking the condenser fan motor ensures it is operating smoothly and prevents further system failures.

How does a technician check for an overcharge of refrigerant in a system?

-A technician can check for an overcharge of refrigerant by examining the suction line temperature. If the suction line is excessively cold, it may indicate liquid refrigerant is returning to the compressor, which is not typical for an overcharged system.

What does the sweating of the compressor indicate in the video example?

-The sweating of the compressor indicates that liquid refrigerant is flowing back into the compressor, which can happen when there is improper refrigerant flow or when the system is overcharged.

What role does experience play in troubleshooting air conditioning systems?

-Experience allows the technician to make informed decisions based on hands-on observations, such as the feel of the suction line or compressor, helping to diagnose issues accurately without relying solely on instruments.

What steps did the technician take to address the frozen system in the service call example?

-The technician defrosted the system by setting the thermostat to allow the indoor fan to run while the compressor was off. After the system thawed, he cleaned the air filter, suspected dirty coils, and performed maintenance on the condenser fan motor.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

HVAC Overview for Beginners | What is HVAC?

Praktek Sistem AC II Cara Mengganti Refrigerant (Freon) II Cara Mengisi Oli Pada Sistem AC

HVAC Systems : Understanding Components and Functionality | Mr. Smart Explains!

Static, Velocity, and Total Pressure Explained

How Air Flows Through the HVAC System of an automobile?

Explaining Superheat and Subcooling to Your Apprentice!

5.0 / 5 (0 votes)