Understanding Poultry Inspection

Summary

TLDRThis video script takes viewers through the detailed process of chicken processing at a plant, emphasizing the rigorous safety and quality controls. After the feathers are removed, the birds undergo evisceration, with the internal organs extracted and the bird cleaned using high-powered vacuums. A modernized inspection system, known as OR-HY, ensures the quality of each bird with trained USDA inspectors overseeing critical food safety tasks, while company personnel handle cosmetic issues like broken wings. The script highlights the comprehensive measures, including bacterial testing and residue analysis, that ensure every chicken product meets USDA safety standards before reaching consumers.

Takeaways

- 😀 The chicken processing process begins with the removal of feathers, followed by the evisceration line where internal organs are removed and the inside of the bird is cleaned.

- 😀 The evisceration process is highly automated due to the uniformity and health of modern chickens, making it efficient and consistent.

- 😀 After the birds are eviscerated, they go through a modernized OR (Online Reprocessing) system for quality inspection by trained company personnel.

- 😀 Company personnel are responsible for inspecting chickens for quality defects like broken wings or bruises, but these issues do not impact food safety.

- 😀 The modernized OR system moves one USDA inspector to the end of the evisceration line, allowing other inspectors to focus on food safety tasks like testing for salmonella.

- 😀 Traditional inspection involved two USDA inspectors stationed along the evisceration line, working with company helpers to remove defects.

- 😀 The modernized system allows for a more specialized role for USDA inspectors, improving overall efficiency and focus on food safety.

- 😀 After inspection, the birds are thoroughly washed, and any defects that were marked by the company personnel are removed.

- 😀 USDA inspectors perform a final inspection at the end of the line to ensure that all safety and quality checks are met before the chicken moves to the chilling process.

- 😀 In addition to visual inspection, chickens undergo bacterial testing, residue analysis, and pass through a metal detector to ensure food safety.

- 😀 Whether using traditional or modernized inspection systems, the goal is the same: to meet or exceed USDA safety standards before the chicken reaches consumers.

Q & A

What happens to the chickens immediately after the feathers are removed?

-After the feathers are removed, the chickens move to the evisceration line, where the internal organs are removed and the inside is cleaned with a high-powered vacuum.

How does the modernized system of inspection differ from the traditional system?

-In the modernized system, one USDA inspector is stationed at the end of the evisceration line and inspects each bird after it has been cleaned, while in the traditional system, USDA inspectors work alongside company employees at the middle of the evisceration line to check for defects during the process.

What is the role of company personnel in the inspection process?

-Company personnel are responsible for inspecting each bird for defects such as broken wings, feathers, bruises, and other issues that impact the chicken's quality. They work closely with USDA inspectors in both the traditional and modernized systems.

What kind of training do the employees who inspect the chickens receive?

-Employees undergo extensive training, which includes both classroom education and hands-on experience to ensure they are fully equipped to carry out their inspection responsibilities effectively.

What happens after the chicken is inspected by company personnel?

-Once inspected by company personnel, the chickens are thoroughly washed inside and out to remove any possible loose materials. Afterward, any defects previously marked are removed by another plant employee.

How do USDA inspectors ensure the chickens are safe for consumption?

-USDA inspectors examine each bird after all cleaning steps have been completed. They also check for safety issues such as bacterial contamination, including salmonella, and ensure that any safety-related concerns are addressed.

Can a USDA inspector stop the processing line?

-Yes, a USDA inspector stationed at the end of the evisceration line has the authority to shut down any portion of the line if they identify a problem during their inspection.

What happens to the chicken after it has passed USDA inspection?

-After passing USDA inspection, the chicken is rinsed one last time, chilled, and then sent for further processing, such as cutting, deboning, or packaging whole.

What other safety tests are conducted on the chicken during the inspection process?

-Apart from visual inspection, chickens are tested for bacterial contamination, such as salmonella, and may also be tested for chemical residues. Additionally, they are passed through a metal detector.

Do both traditional and modernized inspection systems ensure the same safety standards?

-Yes, whether the plant operates under the traditional or modernized system, both methods apply the same rigorous food safety standards as set by the USDA to ensure the chicken is safe and high-quality before reaching consumers.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

FARMFOOD360° Virtual Food Tour: Milk Processing

Você sabe como funciona a linha de produção de um frigorífico de galinhas congeladas?

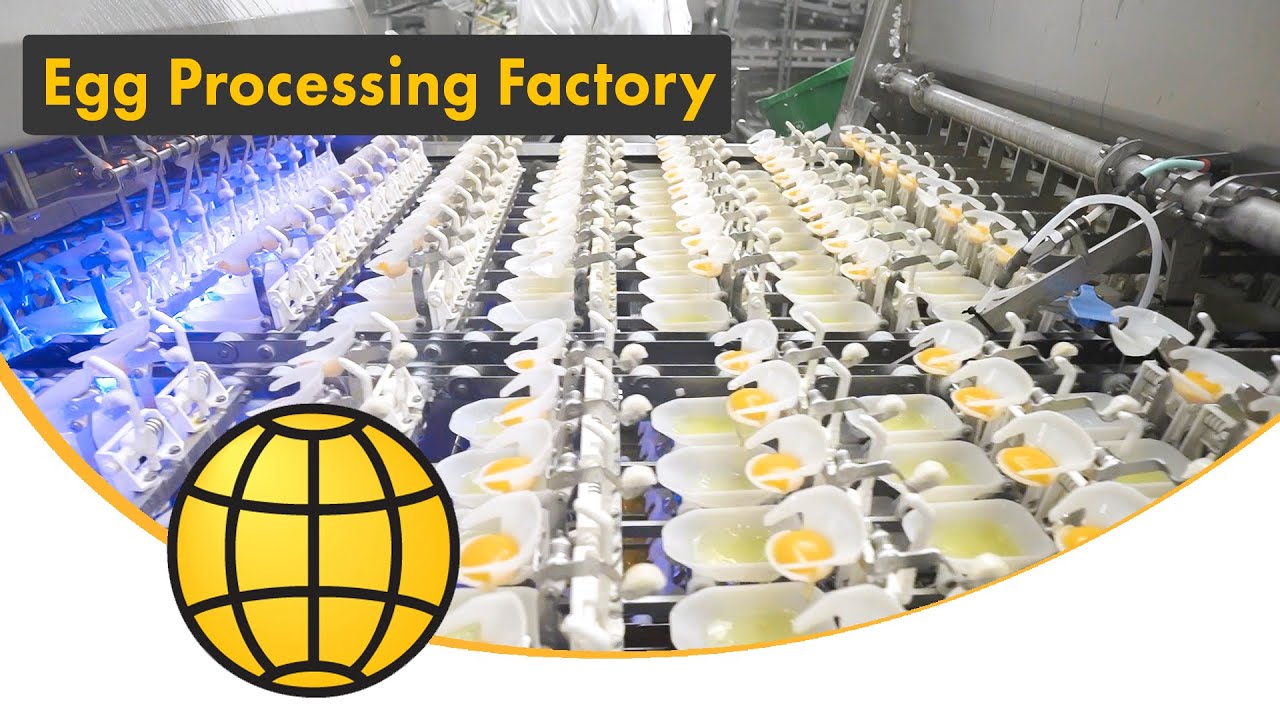

Egg Breaking & Processing Factory - Advanced Egg Processing Machines in Action [BreakerPro] (2024)

Modern Chicken Meat Processing Factory | Chicken Factory

Beginilah Proses Pembuatan Snack Kentang Lay's Di Pabrik Modern!

How Peanut Butter Is Made In Factory | Peanut Butter Factory Process

5.0 / 5 (0 votes)