Esfuerzo Cortante: Ejemplos y Ejercicios Resueltos ✅ [Pernos y Placas] Mecánica de Materiales Fácil

Summary

TLDRThis educational video script discusses shear stress, a crucial concept in material resistance and engineering calculations for structures. It explains shear stress as the force that tends to cause a body to cut or slide relative to another part. The script illustrates this with examples, such as a load applied to two connected plates causing material to shear. It further explains the formula for shear stress, which is force per area, and applies it to practical examples like calculating the shear stress on bolts joining steel plates under a load. The video also includes exercises to help viewers practice calculating shear stress in different scenarios.

Takeaways

- 🔧 Shear force is a concept in material resistance that is crucial for engineering calculations involving structures.

- ⚙️ Shear force occurs when forces are applied to a body with the tendency to cause one part to slide or cut relative to another.

- 📐 The principle of shear force is demonstrated by a simple example of two plates with a load applied, causing the material to tend to cut.

- 📉 The formula for shear stress is force per unit area, similar to the formula for stress but applied in a different plane.

- 🔩 When calculating shear stress, it's important to consider how the load is distributed among multiple bolts or connectors.

- 📊 The example of three bolts used to join steel plates under a 12,000-pound load illustrates how shear stress is calculated per bolt.

- 🔢 In the example, each bolt carries one-third of the total load, which is 4,000 pounds, and is used to calculate shear stress.

- 📐 The area over which the force is applied is crucial in the calculation of shear stress, often involving the diameter squared of the bolt.

- 🔄 Different configurations of plates and bolts require adjustments in the calculation of shear stress, such as dividing the load by two in certain setups.

- 📝 Practice exercises are provided to apply the concept of shear stress calculation, including scenarios with varying numbers of plates and bolts.

- 🚫 The maximum force that can be applied without exceeding the shear stress limit is calculated by considering the given shear stress and bolt diameter.

Q & A

What is shear stress?

-Shear stress is the internal force within a material that resists forces tending to cause one part of the material to slide alongside the other. It is calculated as the force applied per unit area.

How is shear stress applied in engineering?

-Shear stress is used in engineering calculations for structures, particularly to determine the strength of materials under forces that could cause them to break or slide.

What is the formula for calculating shear stress?

-The formula for calculating shear stress is Shear Stress = Force / Area, where Force is the force causing the shear and Area is the area over which the force is applied.

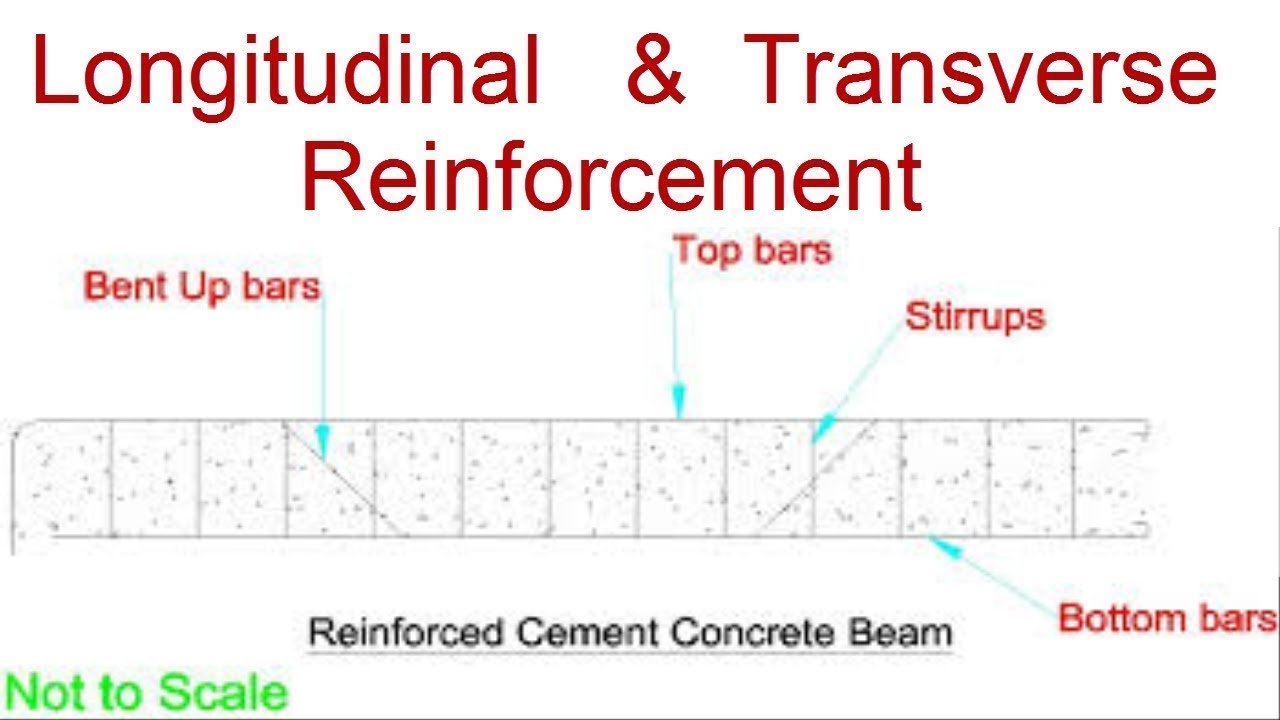

What is the significance of the image with two plates and a load in the script?

-The image with two plates and a load illustrates the concept of shear stress. The load applied to the plates tends to cause one plate to slide over the other, demonstrating the principle of shear stress.

Why is it important to calculate the shear stress on bolts?

-Calculating the shear stress on bolts is important to ensure that the bolts can withstand the forces applied to them without failing, thus maintaining the structural integrity of the assembly.

In the example with three bolts and a 12,000-pound load, how is the load distributed among the bolts?

-In the example, the 12,000-pound load is evenly distributed among the three bolts, with each bolt experiencing a shear stress of 4,000 pounds.

What is the significance of the diameter of the bolt in shear stress calculations?

-The diameter of the bolt is significant because it determines the area over which the force is distributed, which in turn affects the shear stress experienced by the bolt.

How does the configuration of the plates affect the shear stress on the bolts?

-The configuration of the plates affects the shear stress on the bolts by altering the distribution of the applied force. For example, in a setup with plates above and below, the force is divided between two planes.

What is the result of the shear stress calculation for the bolt in the second example with 6,000 pounds of force?

-The result of the shear stress calculation for the bolt in the second example is 6,790 pounds per square inch, after considering that the force is divided between two planes.

How does the number of bolts affect the shear stress each bolt experiences?

-The number of bolts affects the shear stress each bolt experiences by dividing the total force among the bolts. More bolts mean each bolt experiences less shear stress.

What is the purpose of the exercises mentioned in the script?

-The exercises are designed to practice calculating shear stress in different scenarios to understand how to apply the concept and ensure the correct selection of materials and dimensions for engineering applications.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード5.0 / 5 (0 votes)