Recrystallization

Summary

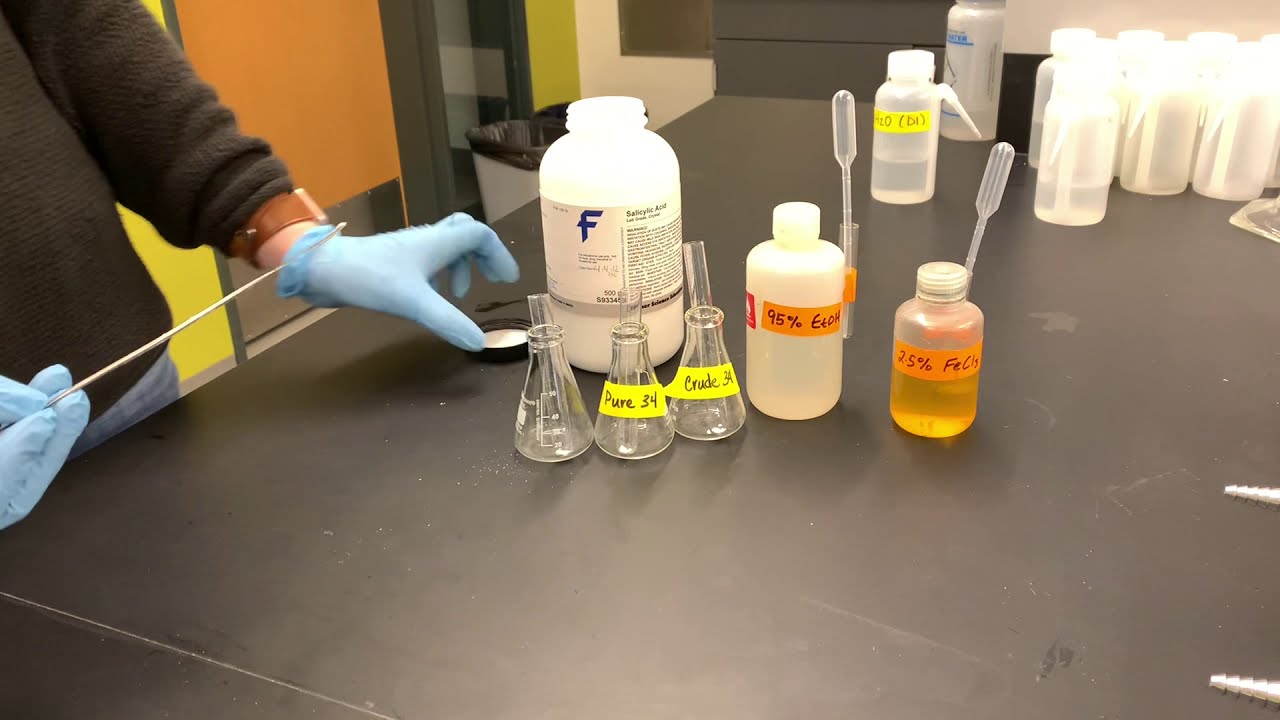

TLDRThis video demonstrates the process of recrystallizing an organic compound. The necessary equipment includes a flask with the compound, a hot plate, recrystallizing solvent, boiling chips, and a filtration setup. The process involves dissolving the compound in a heated solvent, adding activated charcoal to remove impurities, filtering, and cooling the solution to form crystals. The crystals are then collected using vacuum filtration and washed with cold solvent. Finally, the crystals are dried by pulling air through them, completing the recrystallization process.

Takeaways

- 🧪 The video demonstrates the recrystallization process of an organic compound.

- 🔥 Essential equipment includes a pipette, flasks, hot plate, boiling chips, and a filtration assembly.

- 💡 The recrystallizing solvent is heated until it is just barely boiling, ensuring it's near the solvent's boiling point.

- 🌀 Small portions of solvent are added to dissolve the compound, aiming to create a saturated solution with minimal excess.

- 🖤 Activated charcoal can be used to remove color impurities after slight cooling of the solution.

- 🔄 Insoluble impurities and charcoal are filtered out using fluted filter paper and a warm flask.

- ❄️ After filtering, the solution is allowed to cool to room temperature and then placed in an ice bath to enhance crystallization.

- 💧 Crystals are collected using vacuum filtration with a Buechner funnel and cold recrystallizing solvent.

- 🧊 The crystals are washed with cold solvent to remove any remaining supernatant liquid.

- 💨 The drying process starts by pulling air through the crystals, followed by letting them dry completely in open air.

Q & A

What equipment is required for the recrystallization process demonstrated in the video?

-The required equipment includes a Pasteur pipette, a flask containing the compound to be recrystallized, a hot plate, a flask with recrystallizing solvent, boiling chips, a stemless funnel, fluted filter paper, and another flask for receiving the filtrate.

Why is it important to adjust the hot plate to just barely boil the recrystallizing solvent?

-It is important to adjust the hot plate so the recrystallizing solvent is just barely at a boil to prevent rapid boiling, which can cause solvent loss and potential degradation of the compound. The goal is to keep everything near the solvent's boiling point to effectively dissolve the material.

What is the purpose of adding small portions of solvent to the compound during the recrystallization process?

-Small portions of solvent are added to the compound to create a saturated solution, ensuring that the compound dissolves. The goal is to add just enough solvent for saturation and then a little excess to prevent undissolved impurities.

What should you do if the solution has a slightly yellow cast?

-If the solution has a yellow cast, activated charcoal is added to the solution to remove the color. The solution is then swirled and warmed again on the hot plate before filtering out the impurities.

What is the purpose of using activated charcoal in the recrystallization process?

-Activated charcoal is used to remove color impurities from the solution, which may be present due to impurities in the compound or solvent.

Why is it important to keep the filtration apparatus warm during the hot filtration step?

-The filtration apparatus is kept warm to prevent premature crystallization in the filter or funnel, which can trap the desired compound along with the impurities.

How do you complete the recrystallization process after room temperature cooling?

-After cooling the solution to room temperature and observing crystal formation, the flask is placed in an ice water bath to further complete the crystallization process by enhancing crystal growth.

What is the role of vacuum filtration in the recrystallization process?

-Vacuum filtration is used to collect the recrystallized crystals. It involves using a Büchner funnel, filter paper, and a vacuum source to separate the crystals from the remaining solvent and impurities.

Why is cold recrystallizing solvent used to wash the crystals during filtration?

-Cold recrystallizing solvent is used to wash the crystals during filtration to prevent them from dissolving again, while removing any remaining impurities or supernatant liquid adhering to the crystals.

How are the crystals dried after filtration?

-The crystals are dried by pulling air through them using the vacuum for a few minutes, and then they are transferred to a watch glass and left in open air to dry completely.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード5.0 / 5 (0 votes)