O que é Cross Docking? Como funciona? Como montar uma operação logística para e-commerce.

Summary

TLDRIn this video, Thiago Neves introduces cross-docking, a cost-effective and efficient logistics strategy that simplifies distribution by quickly moving goods from suppliers to customers without storage. He explains how cross-docking reduces operational costs, accelerates delivery times, and improves customer satisfaction. Thiago also covers the different types of cross-docking: continuous, hybrid, and distribution, highlighting their unique benefits. He emphasizes the importance of planning, training, and strong communication for a smooth operation, and shares the key advantages such as reduced theft, improved control, and lower capital expenditure.

Takeaways

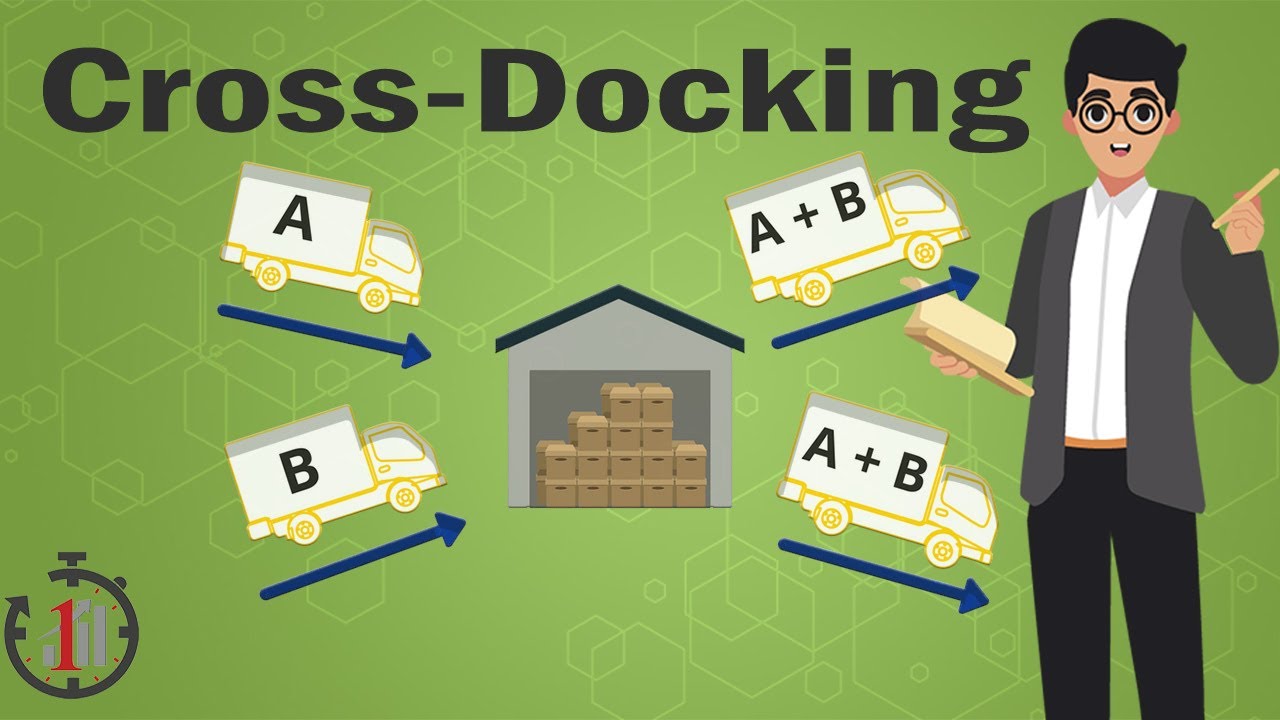

- 😀 Cross-docking is a logistics process where goods are received, sorted, and redistributed quickly, without long-term storage.

- 😀 Cross-docking reduces operational costs by eliminating the need for long-term storage and minimizing handling time.

- 😀 It helps streamline distribution by fragmenting large shipments into smaller deliveries for final customers.

- 😀 This method is fast, with average operation time ranging from 12 hours to 3 days, helping to keep costs low and efficiency high.

- 😀 Key aspects of cross-docking include speed, low cost, and agility, requiring strict adherence to deadlines and smooth communication.

- 😀 A successful cross-docking operation relies on well-planned logistics, trained personnel, and effective communication with both internal teams and external partners.

- 😀 Investment in logistics management software, such as Transportation Management Systems (TMS) and Warehouse Management Systems (WMS), is critical for tracking inventory and improving process efficiency.

- 😀 Cross-docking involves collaboration with third-party transport companies, who handle the physical movement and distribution of goods.

- 😀 There are three common types of cross-docking: continuous movement, hybrid movement, and distribution movement, each with unique logistical and delivery needs.

- 😀 The main benefits of cross-docking include lower customer costs, faster delivery times, better control over product handling, and higher customer satisfaction due to more reliable timelines.

- 😀 Cross-docking also reduces the risk of theft and product loss since goods are not stored for long periods and are handled by multiple responsible parties throughout the process.

Q & A

What is cross-docking in logistics?

-Cross-docking is a logistics practice where goods are directly transferred from the supplier to the distributor or customer with minimal storage time. The items are received, sorted, and immediately dispatched to their final destination.

What are the main characteristics of cross-docking?

-The main characteristics of cross-docking include: it is not a storage method, but a distribution point; goods are quickly fragmented and redistributed; and it operates with minimal delays, typically within 12 hours to 3 days.

How does cross-docking help reduce costs?

-Cross-docking reduces costs by eliminating the need for extensive warehousing and storage facilities. It consolidates the handling process, reducing labor and storage costs while speeding up the delivery to customers.

What are the different types of cross-docking models?

-The three main types of cross-docking are: 1) Continuous Movement, where products are directly transferred from suppliers to customers; 2) Consolidated/Hybrid Movement, where some goods are stored briefly and others are combined into new orders; and 3) Distribution Movement, where large shipments are distributed by dedicated vehicles to multiple locations.

Why is timing critical in cross-docking operations?

-Timing is crucial because the efficiency of cross-docking relies on rapid handling and movement of goods. Delays can disrupt the entire distribution process, leading to operational inefficiencies, customer dissatisfaction, and increased costs.

What role do software systems play in cross-docking?

-Software systems like Transport Management Systems (TMS) and Warehouse Management Systems (WMS) are essential in cross-docking operations. They help track goods, manage inventory, optimize routes, and ensure seamless communication and coordination between suppliers, distributors, and customers.

How does communication impact the success of cross-docking?

-Effective communication is key in cross-docking. Clear and timely communication between all stakeholders—such as suppliers, distributors, and internal teams—helps avoid errors, delays, and misunderstandings, ensuring smooth operations and timely deliveries.

What are the advantages of cross-docking for companies?

-The advantages of cross-docking include reduced operational costs, faster delivery times, better control over inventory and delivery processes, lower capital requirements, and a reduction in theft or product loss during transit.

How does cross-docking enhance customer satisfaction?

-Cross-docking enhances customer satisfaction by speeding up delivery times, ensuring more accurate and timely deliveries, and reducing errors in product shipments. This leads to higher reliability and customer trust.

What are some common challenges in implementing cross-docking?

-Common challenges include the need for precise coordination, strict adherence to schedules, potential issues with inventory management, and the requirement for proper training of staff. Additionally, relying on third-party transport and logistics providers can introduce complexity in maintaining consistency and quality.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

What is Cross-Docking in Supply Chain Management?

MENYIMPAN BARANG HANYA DALAM WAKTU 24 JAM SAJA (CROSSDOCKING)

A Canção da Cadeia Logística! #logistica #qualificacao #logistics #logistika #scm #caminhão #estrada

WALMART's SUPPLY CHAIN CASE STUDY | SCM | SUPPLY CHAIN ANALYTICS | EDI | DRONE | MBA CASE STUDY

Manajemen Logistik

SIKLUS KEGIATAN LOGISTIK DAN PERGUDANGAN

5.0 / 5 (0 votes)