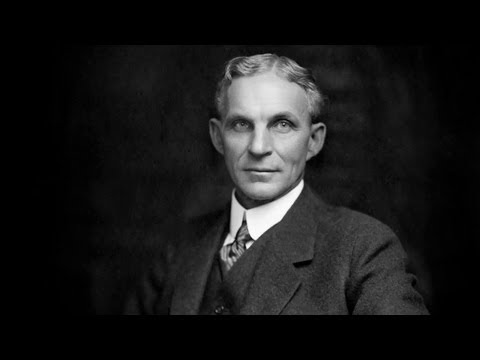

How Ford Built America - The Man Behind The Automobile

Summary

TLDRThis video explores the life and innovations of Henry Ford, a pivotal figure in American industrial history. Born in a farming community, Ford's early fascination with technology led him to Detroit's burgeoning industrial scene. His work with steam engines and later, the gas engine, laid the groundwork for his automotive empire. Ford's introduction of the assembly line revolutionized car production, making the Model T accessible to the masses and transforming the American automotive industry. The video also touches on Ford's strategic business moves, including price reductions and the use of vanadium steel, which contributed to the Model T's dominance in the early 20th century.

Takeaways

- 🔧 Henry Ford was a pivotal figure in American industrialization, revolutionizing the automotive industry.

- 🚜 Born on a farm, Ford developed a strong aversion to manual labor and a passion for technology, leading him to leave his village for Detroit's burgeoning industrial scene.

- ⚙️ Early exposure to steam engines and machinery sparked Ford's interest in innovation, which he pursued by repairing watches and later, more complex steam engines.

- 🏭 Detroit's rapid industrial growth provided Ford with ample opportunities to work with advanced technology and machinery, shaping his future endeavors.

- 🚗 Ford's initial foray into automotive engineering was marked by the creation of the Quadricycle, a rudimentary vehicle that laid the groundwork for his future innovations.

- 🔩 The Detroit Automobile Company, Ford's first venture, faced challenges with supply chain logistics and production efficiency, leading to its eventual dissolution.

- 🔄 Ford's visit to a Chicago slaughterhouse inspired the concept of the assembly line, which he adapted to revolutionize car manufacturing.

- 📈 The introduction of the Model T, built with vanadium steel, marked a significant leap in automotive quality and affordability, propelling Ford to the forefront of the industry.

- 💹 Ford's strategy of reducing car prices while increasing production volumes allowed him to dominate the market, making automobiles accessible to the average American.

- ✒️ In his autobiography, Ford not only documented his experiences but also provided business insights that remain relevant, showcasing his impact beyond the automotive industry.

Q & A

Who is Henry Ford and why is he significant?

-Henry Ford was one of the most influential American industrialists, known for transforming American life through his company. He is significant for his innovations in manufacturing, particularly the development of the assembly line, which revolutionized industrial production.

What was Henry Ford's initial career path before his involvement in the automotive industry?

-Henry Ford was initially expected to be a farmer, but he developed a strong dislike for farming due to its slow and manual nature. His interest in technology led him to work with steam engines and eventually move to Detroit to work as a mechanic.

How did Detroit's industrial growth influence Henry Ford's career?

-Detroit's rapid industrial growth, fueled by the canal connecting the Hudson River to the Great Lakes, provided Henry Ford with ample opportunities to work with machinery and technology. This environment nurtured his skills and interests, which later contributed to his success in the automotive industry.

What was the significance of the gas engine in Henry Ford's career?

-The gas engine was a significant innovation for Henry Ford because it was lighter and more efficient than steam engines, which were the norm at the time. Its internal combustion process allowed for quicker starts, which was a major advantage over steam engines that required lengthy warm-up times.

Why did Henry Ford work for the Edison Illuminating Company?

-Henry Ford worked for the Edison Illuminating Company to gain knowledge of electricity, which was crucial for understanding the operation of gas engines. His role allowed him to experiment with gas engines during his free time, which was essential for his later innovations.

What was the Quadricycle and why was it a significant step in Ford's journey?

-The Quadricycle was Henry Ford's first attempt at creating a horseless carriage. It was a simple vehicle with an ethanol-powered engine and four bicycle wheels. Despite its rudimentary design and lack of a reverse gear or cooling system, it was a significant step as it marked Ford's entry into automobile manufacturing.

How did Henry Ford's first company, the Detroit Automobile Company, perform?

-The Detroit Automobile Company struggled due to the complexity of producing automobiles at scale and the reliance on external parts suppliers. The company produced only twenty delivery wagons in its first two years, leading to Ford's departure from the company.

What was the turning point for Henry Ford in terms of vehicle design and production?

-The turning point for Henry Ford was his realization that to make automobiles accessible to the average person, he needed to focus on a single, reliable design and streamline the production process. This led to the development of the Model T and the implementation of the assembly line.

How did the assembly line impact the production of Ford's automobiles?

-The assembly line revolutionized automobile production by breaking down the manufacturing process into smaller, specialized tasks. This allowed for a significant increase in efficiency and a reduction in production time, which in turn enabled Ford to produce cars at a much larger scale and lower cost.

What role did vanadium steel play in the success of the Model T?

-Vanadium steel played a crucial role in the success of the Model T as it was more than twice as strong as regular steel and lighter, making the Model T much stronger than its competitors. This superior quality was a key factor in the Model T's popularity and market dominance.

How did Henry Ford's business strategies contribute to the widespread adoption of automobiles in America?

-Henry Ford's business strategies, such as reducing the price of the Model T to increase market share and perfecting the moving assembly line to increase production, made automobiles more affordable and accessible to the average American. These strategies contributed to the widespread adoption of automobiles and the establishment of Ford as a dominant player in the automotive industry.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Fordism 1920s USA

Henry Ford: The Complicated Captain of Industry

HENRY FORD | Chapter 1 | AMERICAN EXPERIENCE | PBS

History of the assembly line part A | What is an assembly line | Business History

LA SEGUNDA REVOLUCIÓN INDUSTRIAL (1850-1914)💡🚘✈️

Frederick Douglass: Crash Course Black American History #17

5.0 / 5 (0 votes)