MENYIMPAN BARANG HANYA DALAM WAKTU 24 JAM SAJA (CROSSDOCKING)

Summary

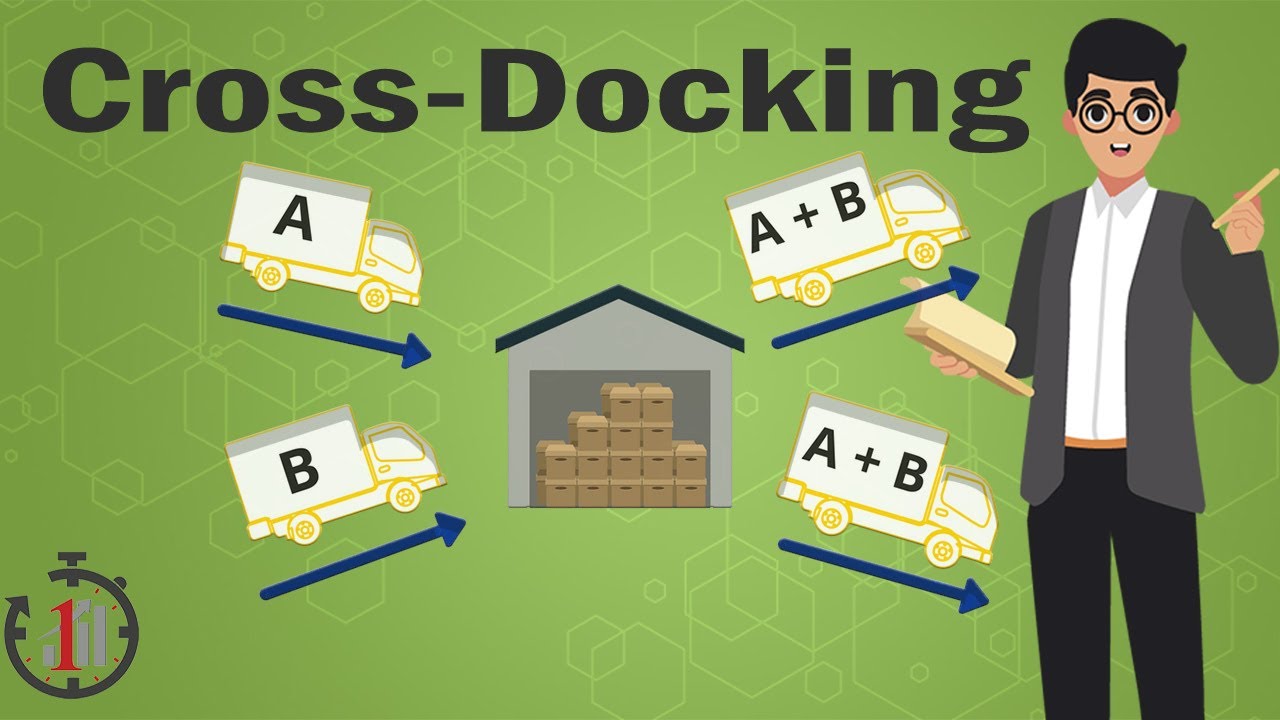

TLDRIn this video, the speaker discusses the concept of Cross Docking as an alternative to traditional warehousing. He explains how it can reduce storage costs and enhance competitiveness by minimizing inventory time. The video compares two types of Cross Docking systems: one where goods are directly received and sent to stores with minimal handling, and another that involves repacking or consolidation of items before delivery. The speaker emphasizes the importance of quality control and timely delivery for both types and concludes that Cross Docking offers an efficient, flexible solution for managing inventory and logistics.

Takeaways

- 😀 Cross docking is a logistics process that minimizes storage time, with goods ideally transferred within 24 hours.

- 😀 Cross docking helps companies reduce **storage costs** and improve their **competitive edge** by cutting holding costs.

- 😀 Zero inventory is an ideal but challenging goal for companies, as it involves managing uncertainties in both demand and supply.

- 😀 The **Just-in-Time (JIT)** system emphasizes having the right amount of inventory when needed, reducing waste and storage costs.

- 😀 Cross docking helps avoid unnecessary storage by directly redistributing goods to stores or customers without significant delays.

- 😀 Cross docking Type 1 involves receiving goods and directly sending them to designated stores with minimal handling.

- 😀 Cross docking Type 2 involves additional consolidation and repackaging before goods are sent to different stores, ensuring better quality control but requiring more work.

- 😀 Companies implementing cross docking must ensure quality control during the receiving and shipping stages to maintain product standards.

- 😀 Cross docking can be a more efficient alternative to traditional inventory management, offering reduced complexity and costs when done properly.

- 😀 Implementing a cross docking system can streamline logistics, helping businesses respond faster to market demand without needing large inventories.

- 😀 The speaker suggests starting small and simple when implementing cross docking, gradually expanding the process as needed.

Q & A

What is cross docking in logistics?

-Cross docking is a logistics strategy where goods are received, sorted, and dispatched within a short period, often within 24 hours, without being stored for long periods. This process reduces inventory holding costs and improves supply chain efficiency.

How does cross docking differ from traditional inventory management?

-Unlike traditional inventory management where goods are stored in a warehouse for extended periods, cross docking minimizes storage time by quickly moving goods from the receiving area to the shipping area, thus reducing storage costs and handling time.

What is the main benefit of implementing cross docking?

-The main benefit of cross docking is the reduction in storage costs and faster delivery times, which leads to improved competitiveness in the market. It allows businesses to quickly meet customer demands without holding excessive inventory.

What is 'Just In Time' (JIT) inventory, and how is it related to cross docking?

-'Just In Time' (JIT) inventory is an approach where goods are only ordered and delivered as needed, minimizing inventory holding. Cross docking supports JIT by ensuring that products are received and immediately dispatched without delay, ensuring timely delivery.

What is the difference between the two types of cross docking?

-The first type of cross docking involves direct unloading of goods into dedicated pallets or boxes for specific stores, requiring minimal handling. The second type involves repacking and consolidating items for different stores, which adds more steps but allows for better control over product quality before shipping.

What are the challenges of Type 2 cross docking?

-Type 2 cross docking involves additional tasks such as repackaging and consolidation of goods for different stores. This requires more labor and time compared to Type 1, making it slightly more complex, but it provides better control over inventory and product quality.

How can businesses benefit from the 'Zero Inventory' model?

-The 'Zero Inventory' model aims to eliminate the need for holding inventory by relying on systems like cross docking, where goods are moved directly from suppliers to customers with minimal storage. This model reduces risk, lowers storage costs, and increases cash flow efficiency.

What role does quality control play in cross docking?

-Quality control is critical in cross docking, especially in Type 2 cross docking where goods are repackaged and redistributed. Ensuring the correct quantity, quality, and timely delivery is essential, and quality checks are performed both during receiving and shipping.

How does cross docking contribute to a company’s competitiveness?

-By reducing inventory holding costs and improving delivery times, cross docking enhances a company's ability to meet customer demands quickly and efficiently, which boosts its competitive edge in the market.

Is cross docking suitable for all types of businesses?

-Cross docking is particularly beneficial for businesses that require fast and efficient movement of goods without long-term storage. However, it may not be suitable for all businesses, especially those that deal with perishable items or highly variable inventory needs.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

5.0 / 5 (0 votes)