Bearings RELIABILITY and Bearings SELECTION in Just Over 10 Minutes!

Summary

TLDRThis video explains how the life of rolling contact bearings follows a Weibull distribution, emphasizing the calculation of bearing life and load ratings based on reliability. The concept of L10 life is discussed, showing how reliability affects bearing life. The Weibull parameters—minimum life, characteristic parameter, and shape factor—are used to adjust for different reliability levels. A detailed example is provided, showing how to calculate the catalog load rating for a bearing, adjusting for factors such as desired life, load, and reliability. The video also touches on the impact of application factors and introduces a future discussion on combined radial and thrust loading.

Takeaways

- 😀 The life distribution of rolling contact bearings is typically not normal but follows a right-skewed Weibull distribution.

- 😀 Bearings often fail before or after the expected 90% reliability life, resulting in a non-symmetrical failure pattern.

- 😀 Weibull distributions can be adjusted for skewness, and the bearing life follows a probability function curve based on reliability.

- 😀 The L10 life value is the number of cycles where only 10% of bearings fail, indicating 90% reliability.

- 😀 In a Weibull distribution, reliability (R) for a given life measure (X) is given by an exponential equation, with specific parameters provided by the manufacturer.

- 😀 The characteristic parameter (theta) represents the 63rd percentile life, while the shape parameter (b) defines how skewed the distribution is.

- 😀 Xnaught is the minimum value of the life variable X, which is statistically derived from manufacturer testing data.

- 😀 The desired bearing life is often expressed as a dimensionless variable (X) in comparison to the manufacturer's rated life (L10).

- 😀 To select a bearing for a specific load and desired reliability, one must adjust for different reliability values using Weibull distribution principles.

- 😀 A deep groove bearing selection example demonstrates how to calculate the catalog load rating (C10) based on desired life, load, and reliability using Weibull parameters.

- 😀 The application factor (Af) is used as a safety factor in bearing selection, ensuring the bearing operates under safe conditions based on the desired reliability.

Q & A

What is the Weibull distribution, and why is it used in bearing life distribution?

-The Weibull distribution is used to model bearing life because it accounts for skewness in failure data. Unlike a normal distribution, which assumes symmetrical failure patterns, the Weibull distribution allows for right-skewed data, which is typical in rolling contact bearings where some samples fail earlier than others, and some last much longer.

What does the L10 bearing life represent, and how is it calculated?

-The L10 bearing life is the number of cycles at which only 10% of the samples have failed, meaning 90% are still operational. It corresponds to the value where the area under the probability function curve from that point onward is 90%.

How does the reliability of a bearing relate to the Weibull distribution?

-In the Weibull distribution, reliability is represented as a function of life, where the reliability (R) for a given life (x) can be calculated using an exponential equation. The value of reliability changes with the shape of the distribution and the life measure, helping to assess the likelihood of bearing failure at different life points.

What do the parameters X₀, θ, and b represent in the Weibull distribution for bearings?

-In the Weibull distribution for bearings, X₀ is the minimum life value where the first sample fails, θ is the characteristic life parameter (63rd percentile of failure), and b is the shape parameter that indicates how much the distribution is skewed. For rolling contact bearings, b is typically close to 1.5.

What is the significance of the dimensionless life measure (x) in bearing selection?

-The dimensionless life measure (x) allows the comparison of different bearing lives by normalizing them with the manufacturer’s L10 life. It helps in adjusting the bearing life for different reliability levels by converting actual life values into dimensionless terms, making calculations more consistent across different designs.

How does the reliability equation help in selecting the correct bearing?

-The reliability equation helps in selecting the correct bearing by allowing the calculation of the required bearing life for a given reliability. By adjusting the life measure (x) for the desired reliability, the equation helps find the load rating (C10) that ensures the bearing will meet the specified life and performance standards.

What does moving from the L10 line to a higher reliability line signify?

-Moving from the L10 line (90% reliability) to a higher reliability line (e.g., 95% or 99%) signifies that the bearing must be able to withstand a greater load or operate for a longer time without failure. This shift represents an increased safety factor to ensure fewer than 10% of the bearings fail within the specified lifespan.

Why is an application factor included in bearing selection, and what does it represent?

-The application factor is included to account for safety in bearing selection. It adjusts the calculated load rating to ensure that the bearing performs reliably under real-world conditions, considering factors like environmental conditions and operational uncertainties.

How can the catalog load rating (C10) be determined for a bearing with a desired reliability higher than the manufacturer's rated reliability?

-To determine the catalog load rating (C10) for a higher reliability than the manufacturer’s rated 90%, you calculate the dimensionless life for the desired reliability (e.g., 99%), then use the Weibull distribution equation to adjust the life and find the corresponding load rating, ensuring the bearing meets the new reliability requirement.

In the example problem, why is the catalog load rating (C10) significantly higher than the applied load?

-In the example, the catalog load rating (C10) is significantly higher than the applied load because the desired bearing life is much longer (420 million cycles vs. 1 million cycles), and a higher reliability (99% vs. 90%) is required. This results in a more robust bearing selection to ensure longevity and reliability under more stringent conditions.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

How do ball and roller bearings work? Types and durability calculation. DIN ISO 281

RELIABILITY Explained! Failure Rate, MTTF, MTBF, Bathtub Curve, Exponential and Weibull Distribution

Fan Bearing Differences: Fluid Dynamic, Ball, Hydro Dynamic, & Sleeve Explained, ft. Noctua

Tips Mudah Menentukan Ukuran Pondasi Cakar Ayam Rumah 2 Lantai

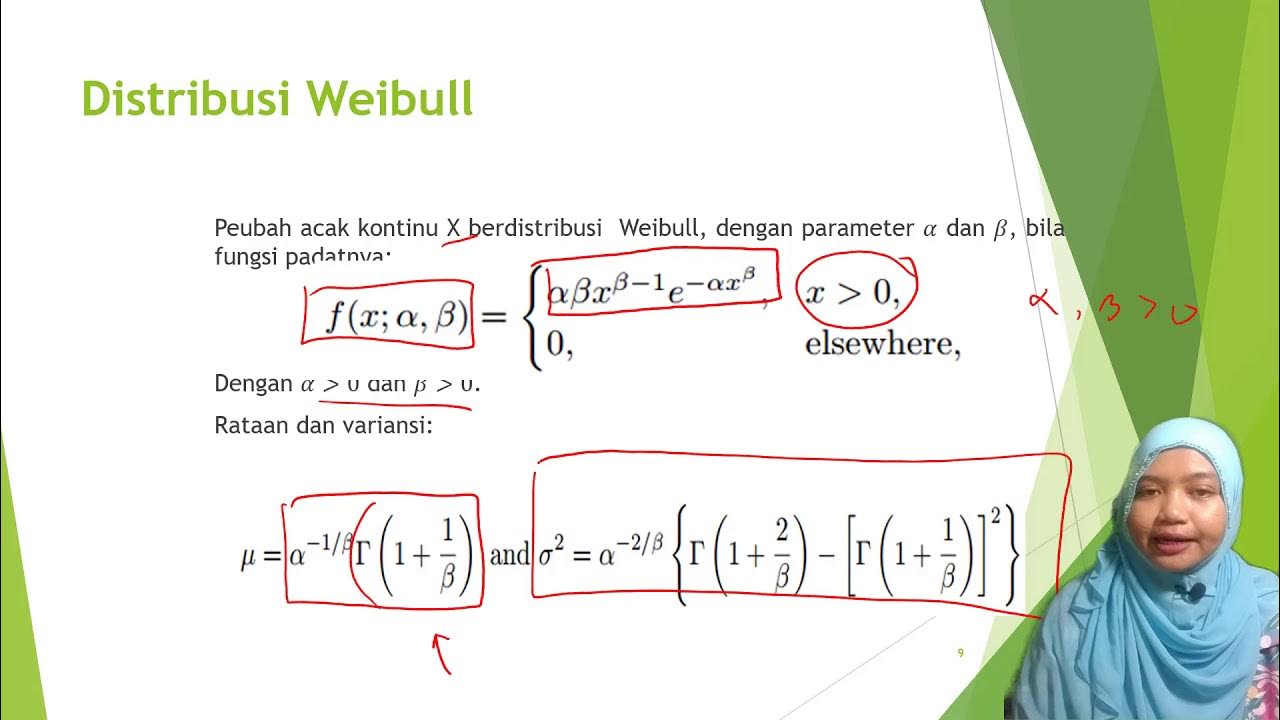

Distribusi Chi-square, Weibull, t dan F

GCSE Maths - What are Bearings? (2026/27 exams)

5.0 / 5 (0 votes)