Epoxy resins | Mechanism of Synthesis | Applications | Synthesis of epoxy resins

Summary

TLDRThe transcript explores the properties, characteristics, and applications of versatile polymers, focusing on their mechanical, chemical, and insulating properties. It covers their use in industries like aerospace, electronics, and construction, highlighting their high-temperature resistance, stability, and low cost. The video illustrates how these materials are integral in various engineering fields, from medical devices to decorative flooring.

Takeaways

- 😀 The polymer discussed is highly versatile and can be modified to suit various applications.

- 😀 It demonstrates strong mechanical properties, allowing it to maintain its shape under stress.

- 😀 The polymer offers excellent insulation properties, making it ideal for electrical and electronic applications.

- 😀 It is cost-effective, making it a practical choice for widespread use across different industries.

- 😀 This polymer has strong resistance to high temperatures, ranging from -5°C to 150°C, making it suitable for extreme environments.

- 😀 Its cross-linking enhances its mechanical strength, chemical stability, and durability under stress.

- 😀 The polymer contains hydroxyl groups, improving its chemical resistance and making it versatile in chemical applications.

- 😀 It has applications in diverse sectors such as aerospace, automotive, medical, and construction industries.

- 😀 The polymer is used for coatings, such as anti-corrosion and anti-oxidation coatings for pipes and appliances.

- 😀 The material is utilized in high-voltage insulators, and in electronic packaging due to its stability and insulating properties.

- 😀 It is also used in manufacturing lightweight parts for racing cars, bikes, musical instruments, and decorative flooring.

Q & A

What are the key properties of polymers discussed in the script?

-The key properties of polymers discussed include their versatility, low shrinkage, excellent insulation, high mechanical strength due to cross-linking, chemical resistance, and the ability to maintain their shape under long-term stress.

Why are certain polymers considered versatile and useful in a variety of applications?

-Certain polymers are versatile because they can perform well under different environmental conditions, offering flexibility, resistance to chemicals and heat, and strong mechanical properties that make them suitable for diverse uses such as coatings, insulation, and automotive parts.

How do the mechanical properties of polymers improve with cross-linking?

-Cross-linking increases the strength of the polymer by bonding the individual polymer chains together. This enhances its mechanical properties, making it more durable and resistant to physical stress, resulting in stronger, more stable materials.

What are the applications of polymers in the field of aerospace engineering?

-In aerospace engineering, polymers are used in aircraft for their light weight, high mechanical stability, and resistance to high temperatures and environmental factors. These properties are crucial for ensuring the safety and performance of aerospace components.

How are polymers used in electrical insulation?

-Polymers are used in electrical insulation, especially in high-voltage applications, due to their excellent insulating properties. These polymers prevent electrical leakage, ensuring the safety and functionality of electrical equipment and wiring.

What makes polymers suitable for use in medical and dental applications?

-Polymers are suitable for medical and dental applications due to their chemical resistance, stability, and ability to maintain shape under stress. They are used in dental materials, surgical equipment, and coatings, where strength and biocompatibility are important.

What role do polymers play in the construction industry?

-Polymers play a significant role in the construction industry, particularly in coatings for flooring and decorative elements. Their durability, resistance to wear and tear, and aesthetic versatility make them ideal for construction materials.

Why are polymers used in the production of lightweight automobile parts?

-Polymers are used in automobile parts due to their light weight, strength, and ability to withstand mechanical stress. This helps improve fuel efficiency, reduce vehicle weight, and ensure high performance in automotive designs.

How are polymers utilized in electronic packaging?

-Polymers are used in electronic packaging because of their excellent thermal stability, electrical insulation properties, and protection against environmental factors. They help ensure that electronic components are safely housed and protected from damage.

What are the benefits of using polymers in sports equipment?

-Polymers are used in sports equipment for their lightweight nature, mechanical stability, and resistance to impact. These properties are essential in producing durable, high-performance equipment such as racing cars, golf clubs, and other sports gear.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Kuliah 2 IBK Sifat Mekanis Bahan part 1

Propriedades de utilização

Sifat Fisika dan Kimia Minyak dan Lemak

Important Industrial Polymers | Properties and Applications of PVC | Bakelite | PVAc

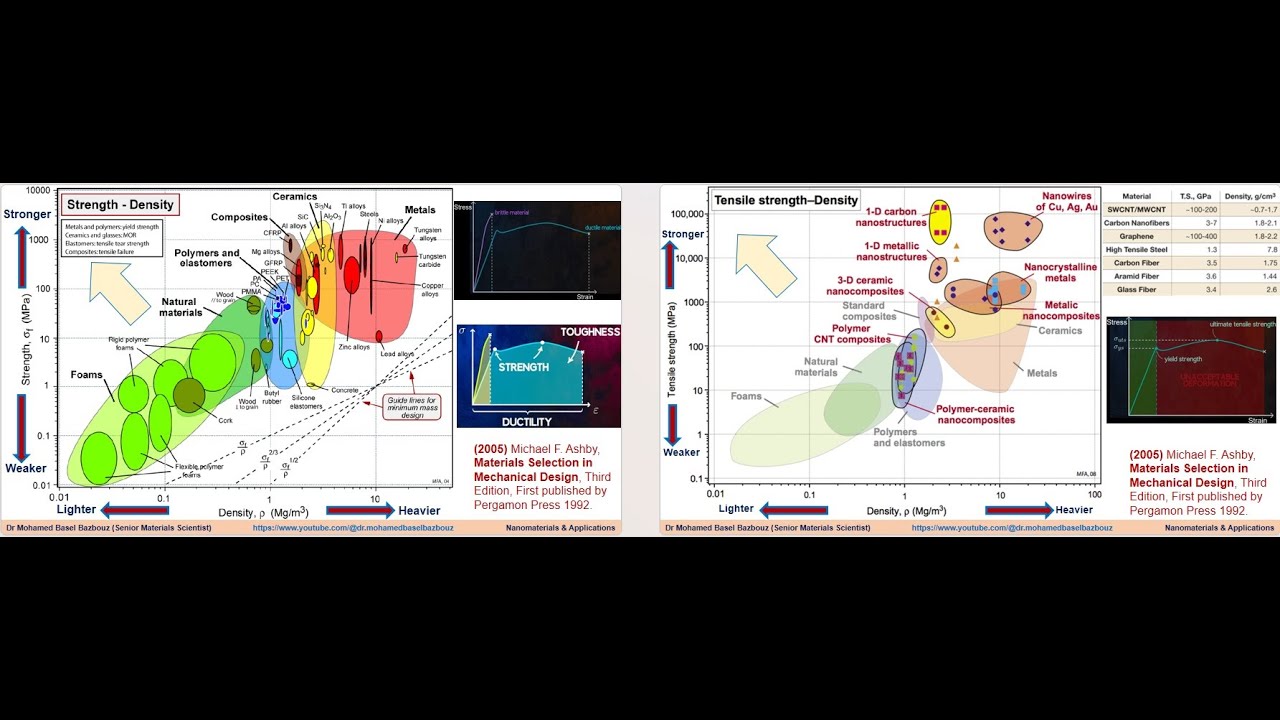

Ashby plots of Strength versus density for materials and nanomaterials المتانة والوزن النوعي

Engineering Materials - Metallurgy

5.0 / 5 (0 votes)