Lab 2 Rock tensile strength: Brazilian test

Summary

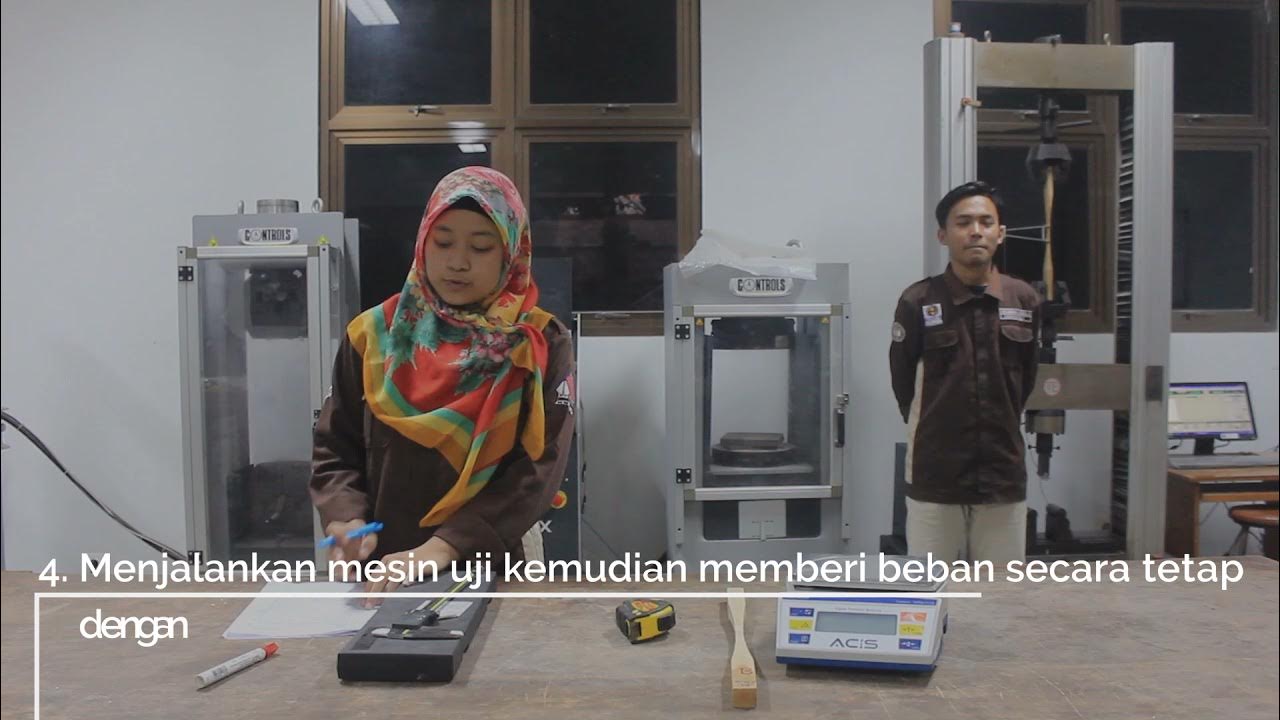

TLDRThis video explains the process of performing a tensile strength test using the Brazilian density strength method. The procedure involves applying force to a cylindrical rock sample, measuring its diameter and length, and observing the fracture point. Key steps include sample measurement, setup of the loading frame, alignment checks, and data analysis. The video highlights how to calculate tensile strength based on the peak load and dimensions of the sample, emphasizing the importance of precision during both the testing and analysis phases.

Takeaways

- 🧪 The focus of this lab (Laboratory 2) is on measuring tensile strength using the Brazilian tensile strength test.

- 📏 The sample used in this test is a cylindrical rock with equal length and diameter, and force is applied along the cylindrical side.

- 💥 The test generates tensile strength, causing a fracture in the rock, and the tensile strength is estimated from the peak load and sample dimensions.

- 📊 Steps in the analysis include sample measurement, loading frame setup, fracturing, and data analysis—similar to Laboratory 1.

- 📐 The diameter is measured in different directions to ensure the sample is as circular as possible, while length measurement is less critical compared to Lab 1.

- 🔄 The alignment of the top and bottom parts of the frame is checked to ensure they are parallel using a level tool.

- ⚙️ The control setup monitors two key parameters: the load and displacement, with displacement measurement being optional in this lab.

- ⏩ Two speeds are used in the setup: one for movement and one for displacement, and the lower frame is raised until it touches the upper frame.

- 🛡️ Protective plastic is placed around the sample in case the rock explodes during the test.

- 📸 After the rock fractures, a force drop is observed, and data is captured for further analysis, including calculating tensile strength based on the peak load.

Q & A

What is the main focus of the laboratory experiment discussed in the transcript?

-The main focus of the laboratory experiment is to measure the tensile strength of a cylindrical rock sample using the Brazilian Tensile Strength test method.

What shape is the rock sample used in the tensile strength test?

-The rock sample used in the tensile strength test is cylindrical, with the diameter and length being the same.

How is the tensile strength generated during the test?

-Tensile strength is generated by applying force along the cylindrical side of the sample, which causes a fracture in the rock.

What are the key measurements needed before starting the tensile strength test?

-The key measurements needed are the diameter and the length of the sample. These measurements help in estimating the tensile strength once the peak load is known.

Why is it important to check the circularity of the sample during the preparation phase?

-It is important to check the circularity of the sample to ensure that the sample is as close to a perfect cylinder as possible. An irregular shape may affect the accuracy of the tensile strength measurement.

How does bedding direction influence the tensile strength test?

-Bedding direction can affect the tensile strength of the sample depending on how the stress is applied during the test. It is important to check for bedding direction before proceeding.

Why is it necessary to level the top and bottom parts of the frame before testing?

-It is necessary to level the top and bottom parts of the frame to ensure that the load is applied evenly across the sample. Misalignment could result in inaccurate measurements.

What are the two main parameters controlled during the tensile strength test?

-The two main parameters controlled during the test are the load and the speed of displacement.

What indicates that the sample has fractured during the test?

-The sample is considered to have fractured when the load applied reaches a peak and then suddenly drops.

How is the tensile strength calculated after the test is completed?

-Tensile strength is calculated using the peak load applied during the test, along with the sample's length and diameter measurements.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

5.0 / 5 (0 votes)