Let the inventory walk and talk | Mick Mountz | TEDxBoston

Summary

TLDRThis script introduces a revolutionary approach to warehouse inventory management using mobile robots, transforming the pick, pack, and ship process. Traditional methods, where workers walk miles to locate items, are replaced with an operator-centric system where robots bring products to pick stations. This not only boosts productivity and accuracy but also enhances worker satisfaction, turning the warehouse into a massively parallel processing engine capable of dynamic, real-time inventory optimization.

Takeaways

- 🛍️ The script introduces a breakthrough approach for managing inventory in a warehouse setting, specifically for Pick, Pack, and Ship operations.

- 🤖 It discusses the use of hundreds to thousands of mobile robots to facilitate the movement of inventory within the warehouse.

- 📦 The traditional method of order fulfillment involves pick workers walking long distances within the warehouse, which is unproductive and unfulfilling.

- 🛒 The speaker shares a personal anecdote from the dot-com boom, highlighting the inefficiencies and high costs of order fulfillment at Webvan.

- 🚀 The idea for a more efficient system came from a brainstorming exercise that considered extreme scenarios, like zero-cost labor, leading to the concept of mobile shelving and robots.

- 🏗️ The practical implementation of this idea involves robots bringing shelves with inventory items to pick stations located at the warehouse's perimeter.

- 👷♀️ The new system allows pick workers to remain stationary, increasing productivity and making their job more satisfying and less physically demanding.

- 🎯 The technology enables high-fidelity picking by using lasers and barcode scanning, which reduces errors and speeds up the process.

- 📈 The system uses dynamic and adaptive algorithms to organize the warehouse floor, adjusting to the popularity of products and seasonal demands.

- 🌐 The approach turns the warehouse into a massively parallel processing engine, allowing for independent operation of multiple pick stations without a single point of failure.

- 📊 The script emphasizes the scalability of the system, which can handle a varying number of pick stations and adapt to the size of the warehouse.

- 🌟 The final takeaway is the transformative impact of the technology on the pick workers' experience, making their job more engaging and even beneficial to their health.

Q & A

What is the main focus of the breakthrough approach discussed in the script?

-The main focus is a new approach for managing inventory in a warehouse setting, specifically in a Pick, Pack, and Ship environment, involving the use of hundreds or thousands of mobile robots.

What is the traditional challenge faced by pick workers in a warehouse?

-Traditionally, pick workers spend 60 to 70% of their day walking around the warehouse, often covering distances up to 5 to 10 miles, searching for items of inventory, which is unproductive and unfulfilling.

Can you explain the speaker's experience with Webvan and its relevance to the current discussion?

-The speaker worked at Webvan during the dot com boom, a company that aimed to deliver grocery orders online but failed due to high costs associated with picking and packing items. This experience highlighted the need for a more efficient picking solution.

What was the idea that emerged from the brainstorming exercise involving a hypothetical distribution center in China?

-The idea was to have a system where products could 'walk and talk' on their own, essentially using mobile robots to bring items to pick workers, eliminating the need for workers to search for items manually.

How does the new approach change the role of pick workers in a warehouse?

-In the new approach, pick workers stay at pick stations on the perimeter of the warehouse, and mobile robots bring items to them, making their job more productive, accurate, and fulfilling as they no longer need to walk around searching for items.

What is the significance of the Beijing Olympics opening ceremony to the speaker's idea?

-The speaker was inspired by the coordinated movement of thousands of people during the opening ceremony, which demonstrated the power of emergence in systems with peer-to-peer coordination and communication, similar to the operation of mobile robots in a warehouse.

How does the new system improve the efficiency of picking and packing orders?

-The system improves efficiency by removing the non-value added steps of walking and searching for items, allowing pick workers to focus solely on picking and packing, with items brought directly to them by mobile robots.

What is the concept of a 'massively parallel processing engine' in the context of the warehouse?

-The concept refers to the warehouse operating like a supercomputer with multiple processors working independently and simultaneously, allowing for high productivity and resilience, as the absence of one worker does not affect the others.

How does the system adapt to changes in product popularity or seasonal demands?

-The system uses dynamic and adaptive algorithms to track product popularity and adjust the warehouse floor layout accordingly, moving high-demand items closer to pick stations during peak times.

What are the side effects of the new approach on the overall warehouse operations?

-The side effects include increased productivity, better accuracy in order fulfillment, and an improved working environment for pick workers, making the job more interesting and less stressful.

How does the speaker conclude the discussion on the impact of the new approach on workers' experiences?

-The speaker concludes by highlighting testimonials from workers who find the new environment more fulfilling and stress-free, with some even reporting improved health outcomes due to the reduced physical and mental strain.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

What is Warehouse Management? [Intro to Inventory Management, Pick Pack Ship, WMS Software, etc]

Kiva Systems Warehouse Automation at Quiet Logistics

Putaway Feature Walkthrough | ShipHero WMS Guides

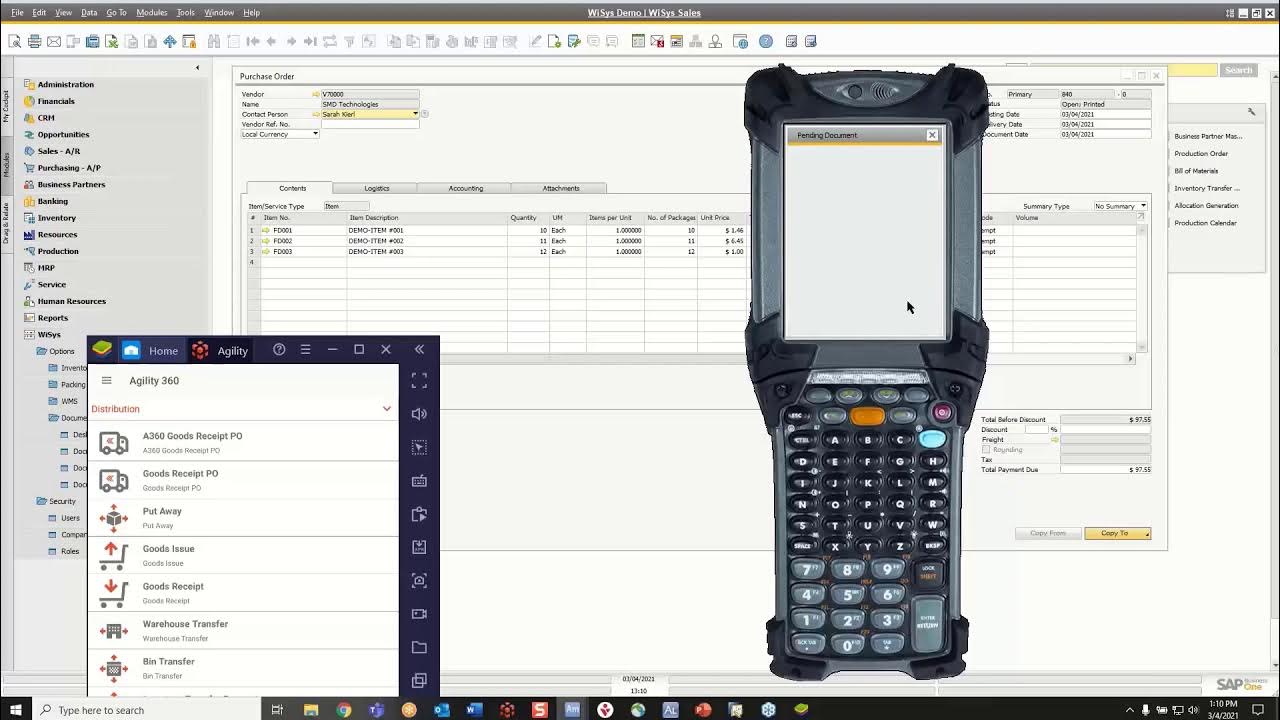

Introduction to WiSys Agility WMS for SAP Business One

How Amazon Is Delivering Packages Faster With The Help Of Generative AI

HO VISTO IL FUTURO!

5.0 / 5 (0 votes)