Heat Transfer - Chapter 8 - Internal Convection - Hydrodynamic Considerations

Summary

TLDRThis video lecture delves into the concept of internal convection, focusing on hydrodynamic considerations and their impact on heat transfer. The lecture compares external convection, where boundary layers form over a heated surface, with internal convection, where boundary layers develop between two parallel surfaces or within pipes. Key topics include fully developed flow, mean temperature in confined fluid systems, Reynolds numbers, and the hydrodynamic entry region. The video also explores the difference in flow characteristics for laminar versus turbulent conditions and provides methods for calculating the hydrodynamic entry length, offering a practical understanding of fluid dynamics in heat transfer scenarios.

Takeaways

- 😀 Internal convection involves the interaction of fluid mechanics with heat transfer in confined spaces like pipes or channels.

- 😀 Unlike external convection, which uses bulk fluid temperature (T infinity), internal convection uses the mean temperature of the fluid as it flows through the channel.

- 😀 Hydrodynamic considerations are crucial in internal convection, particularly in the development of velocity and thermal boundary layers.

- 😀 In fully developed flow, velocity profiles stabilize, and temperature differences are calculated based on T surface minus T mean rather than T surface minus T infinity.

- 😀 The entrance region of a pipe or channel is characterized by developing boundary layers that change the heat transfer characteristics until the flow becomes fully developed.

- 😀 Reynolds number is used to determine flow characteristics like laminar or turbulent flow. For pipe flow, a critical Reynolds number of 2300 indicates the transition from laminar to turbulent flow.

- 😀 The hydrodynamic entry length describes how far into a pipe or channel the flow needs to travel before becoming fully developed. For laminar flow, this is roughly 0.05 times the Reynolds number multiplied by the pipe diameter.

- 😀 For turbulent flow, the hydrodynamic entry length is not dependent on the Reynolds number and typically ranges from 10 to 60 pipe diameters.

- 😀 If the pipe is long enough and the hydrodynamic entry length is small, we can assume the flow is fully developed, simplifying calculations.

- 😀 The next lecture will discuss thermal boundary layers and the thermal entry region, which builds upon the concepts of hydrodynamic entry and fully developed flow.

Q & A

What is the key difference between external and internal convection?

-The main difference is that in external convection, heat is transferred from a surface to the surrounding fluid, with the fluid flowing around the surface. In internal convection, the fluid flows within a confined space like a pipe or channel, and the heat transfer occurs between the surface and the bulk of the fluid within this confined system, where the flow and temperature profiles evolve as the fluid moves along the channel.

What does the term 'fully developed flow' refer to?

-Fully developed flow refers to a state in a pipe or channel where the velocity profile of the fluid no longer changes with further movement along the flow direction. This happens when the velocity and temperature profiles have stabilized, and boundary layers have fully developed and merged.

Why do we use the mean temperature in internal convection instead of T infinity?

-In internal convection, since the system is bounded and the fluid is confined in a channel, the temperature of the fluid changes along the flow direction. Instead of using T infinity (the temperature of the infinite surrounding fluid), we use the mean temperature, which is an average temperature of the fluid within the channel.

What happens in the 'hydrodynamic entrance region' of a pipe or channel?

-In the hydrodynamic entrance region, the fluid flow is still developing. The velocity profile is not yet fully established, and boundary layers are forming on the walls of the pipe or channel. The heat transfer characteristics in this region are different from those in the fully developed flow region.

How is the Reynolds number used in internal convection, and how does it differ from external flow?

-The Reynolds number in internal convection is used to characterize the flow as laminar or turbulent. It is based on the mean velocity, fluid density, pipe diameter, and fluid viscosity. Unlike external flow, the Reynolds number in internal flow remains constant along the length of the pipe since the flow is bounded and the diameter of the pipe is fixed.

What is the significance of the critical Reynolds number of 2300 in pipe flow?

-The critical Reynolds number of 2300 is used to distinguish between laminar and turbulent flow in a pipe. Flow with a Reynolds number below 2300 is laminar, while flow above this value is turbulent. This critical value helps in predicting the flow regime and designing systems for heat transfer and fluid flow.

How do you calculate the hydrodynamic entry length for laminar and turbulent flow?

-For laminar flow, the hydrodynamic entry length is approximately 0.05 times the Reynolds number, multiplied by the pipe diameter. For turbulent flow, the entry length is typically between 10 and 60 times the pipe diameter. This entry length defines how far into the pipe the flow will be developing before it becomes fully developed.

What happens to the flow characteristics as the hydrodynamic entry length becomes a small percentage of the total pipe length?

-As the hydrodynamic entry length becomes a small percentage of the total pipe length, it is assumed that the flow has already reached the fully developed stage throughout most of the pipe. This simplifies calculations and makes the flow profile more predictable for the purposes of heat transfer analysis.

What is the relationship between mass flow rate and mean fluid velocity?

-The mass flow rate (m dot) is the product of the fluid density, mean fluid velocity, and the cross-sectional area of the pipe or channel. The mean velocity can be calculated by rearranging the mass flow rate equation: mean velocity = m dot / (fluid density * cross-sectional area).

How does the mean temperature change along the flow direction in a heated system?

-In a heated system, the mean temperature of the fluid increases along the flow direction due to heat transfer from the walls of the pipe or channel. As the fluid moves through the system, the temperature profile changes, and the mean temperature represents the average of these changes along the flow direction.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Earth's Internal Heat

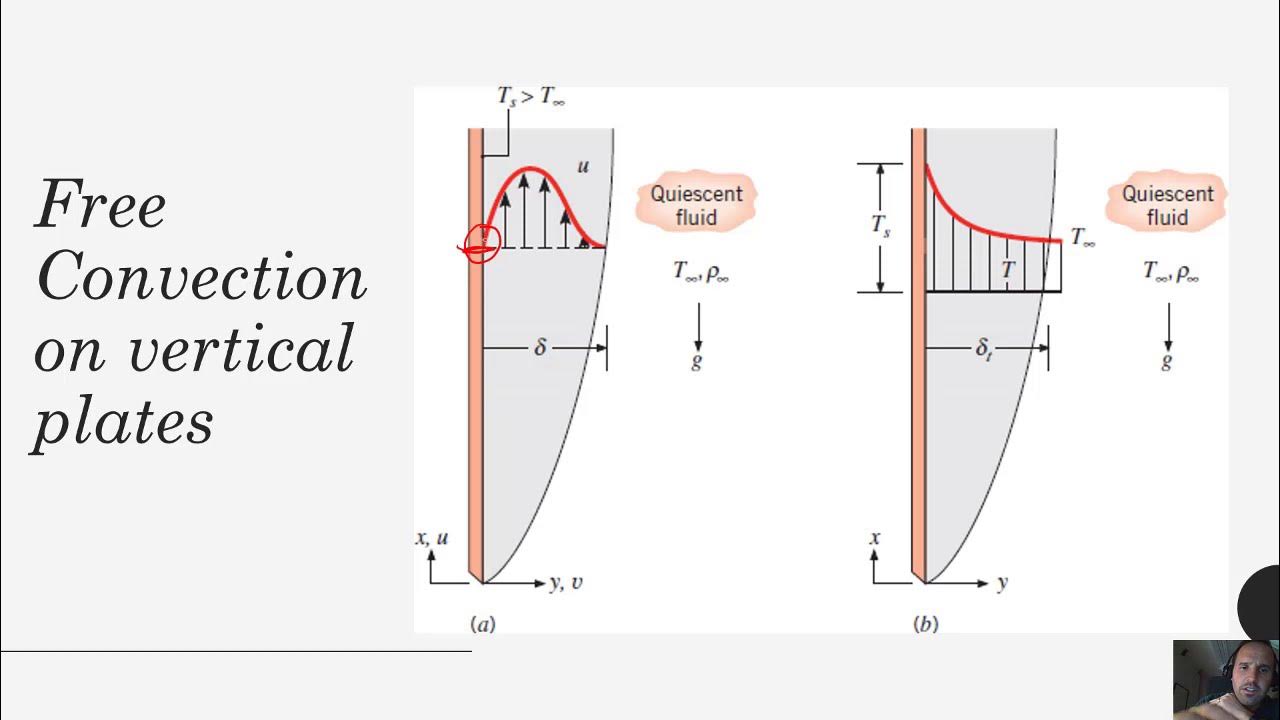

Heat Transfer - Chapter 9 - Conceptual Introduction to Natural (Free) Convection)

Analysis of Temperature Distribution profile of pin fin | Practical No.8 | GTU | 3151909

WHY IS THE EARTH'S INTERIOR HOT? | Sources of Internal Heat | Earth Science

HEAT EXCHANGER BASICS | CLASSIFICATION | MODE OF HEAT TRANSFER | PIPING MANTRA |

Thermal Conductivity, Stefan Boltzmann Law, Heat Transfer, Conduction, Convecton, Radiation, Physics

5.0 / 5 (0 votes)