How to build a car: Inside Hyundai's Czech plant | Drive.com.au

Summary

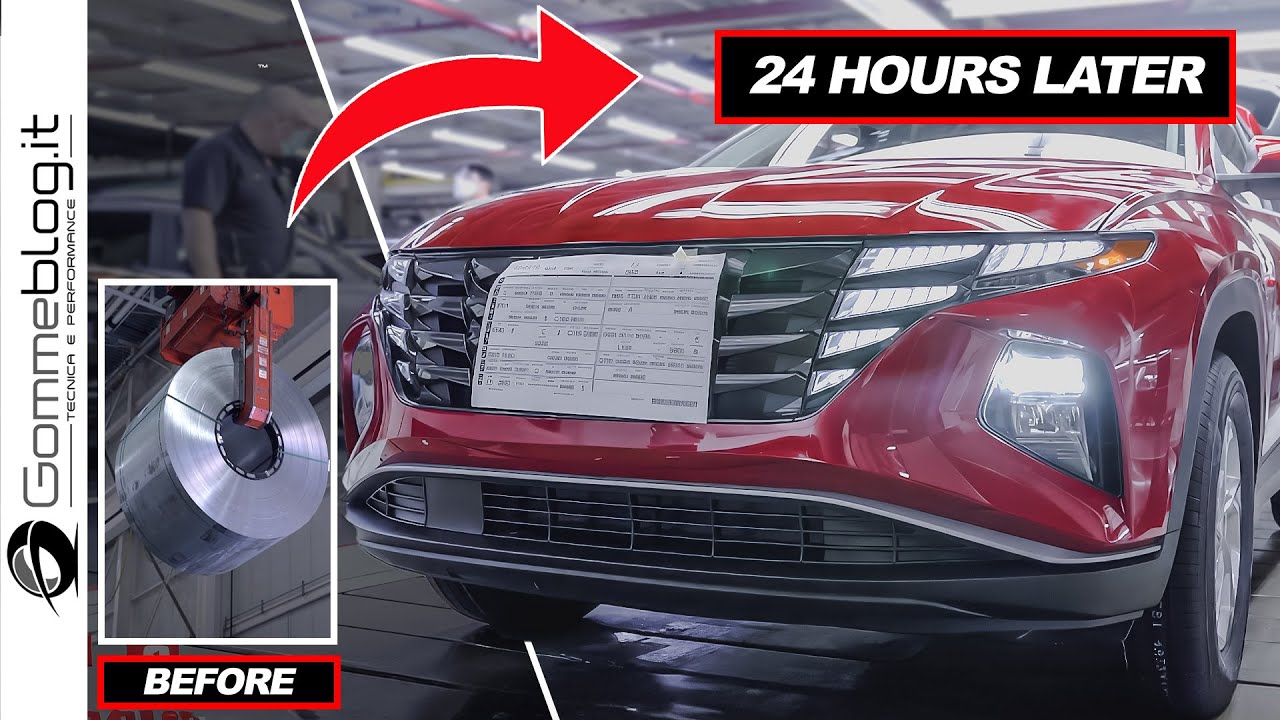

TLDRThe video takes viewers on an exclusive tour of Hyundai's state-of-the-art car manufacturing plant in Ustraa, where a new car is built every 54 seconds. It highlights the immense pressure and precision involved in the stamping process, as well as the robotics and assembly line that bring the car to life. The Hyundai Tucson SUV is a major focus, representing 70% of production. The video also follows the car’s journey, from factory assembly to shipping to Australia. The process showcases the skill, technology, and teamwork behind every vehicle that rolls off the line.

Takeaways

- 😀 The Hyundai Ustraa plant produces a new car every 54 seconds, employing around 3,400 people.

- 😀 The Hyundai Tucson SUV represents around 70% of the plant's production.

- 😀 The stamping plant involves immense forces, with each stamp using over 3,000 tons of pressure.

- 😀 The plant produces three different car models: the Tucson, the I30, and the ix20.

- 😀 Robots are used to weld car panels together in a highly choreographed and efficient manner.

- 😀 It takes a little over 20 hours to build a Tucson, with most of the time spent in the paint shop.

- 😀 The final assembly area is where key components like the engine, transmission, and brakes are installed.

- 😀 The production line is fast-paced, with workers operating under significant time pressure to ensure cars are built quickly and efficiently.

- 😀 The plant produces cars in different variants, including petrol, diesel, two-wheel-drive, and all-wheel-drive models.

- 😀 After production, cars are shipped to Australia via a long journey across the sea, taking several weeks to arrive.

- 😀 After the cars arrive in Australia, they are tested and prepared for the road before being handed over to customers.

Q & A

What is the significance of the Hyundai plant at Ustraa?

-The Hyundai plant at Ustraa is a state-of-the-art car manufacturing facility that produces a new car every 54 seconds and employs around 3,400 people. It plays a key role in supplying cars to numerous countries, including Australia.

What is the primary vehicle produced at the Hyundai Ustraa plant?

-The Hyundai Tucson SUV represents around 70% of the plant's production, making it the primary vehicle produced at the plant.

How does the stamping process work in car production at the plant?

-The stamping process involves changing the dies to accommodate different car models, such as the Tucson, I30, and ix20. The dies are massive, using more than 3,000 tons of pressure, and they create panels like doors, roofs, and bodywork for the cars.

How are robots used in the car manufacturing process at Ustraa?

-Robots are employed to weld together the stamped panels into the basic form of the car. The robots work in a highly coordinated manner, assembling parts like doors in a synchronized, technical ballet.

How long does it take to build a Hyundai Tucson at the Ustraa plant?

-It takes a little over 20 hours to build a Hyundai Tucson at the Ustraa plant, with most of the time spent in the paint shop.

What happens in the final assembly area of the Hyundai plant?

-In the final assembly area, the key components such as the engine, transmission, brakes, and suspension are bolted onto the car, transforming it from a bare metal structure into a complete vehicle.

What is the 'shazzy marriage' section in the production line?

-The 'shazzy marriage' section is where the powertrain, including the engine and gearbox, is bolted into the car's body along with other critical components like brakes and suspension hardware.

How are different types of cars produced on the same production line?

-The production line at Ustraa is flexible enough to accommodate three different car models—Tucson, I30, and ix20—as well as petrol, diesel, two-wheel drive, and all-wheel drive variants. The line adapts to produce a wide variety of cars simultaneously.

What happens after the cars are finished at the Ustraa plant?

-Once the cars are complete, they are shipped out of the factory by train, then travel across the sea to destinations like Australia. This process takes several weeks, and the cars are shielded from the elements by protective plastic.

What happens after the Hyundai cars arrive in Australia?

-After the cars arrive in Australia, a final check is performed, and the cars are prepared for their first drive, which is a crucial step before they are released to customers.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Entré a la fábrica de autos más rápida de América: ¡un coche por minuto! 🚗😱

What's REALLY Happening Inside Hyundai's TUCSON Manufacturing Plant

Salah Satu Bengkel Proper di Bandung !!!

How to build a £2million Bugatti Chiron

MOMENT LANGKA!!! LIHAT LANGSUNG PRODUKSI TOYOTA YARIS CROSS DI PABRIKNYA!!! WAJIB TONTON! | GridOto

LAPTOP SI UNYIL 19 JANUARI 2016 - NYAMAN SAAT JALAN JALAN 3-1

5.0 / 5 (0 votes)