12 Aspek CPOB (2012) SMK Farmasi

Summary

TLDRThis video discusses Good Manufacturing Practices (GMP) in pharmaceutical production, particularly in Indonesia, as outlined by BPOM. It highlights the 12 key aspects of Good Manufacturing Practices (CPOB) that ensure drug quality, such as quality management, sanitation, and production control. The video emphasizes that pharmaceutical industries and institutions, like hospitals, must apply CPOB to maintain high standards. It is aimed at vocational students in pharmacy, providing an introduction to CPOB as a vital framework for the safe and effective manufacturing of medicines.

Takeaways

- 😀 Good Manufacturing Practice (GMP) ensures that drugs are produced consistently according to established quality standards.

- 😀 GMP is crucial for the pharmaceutical industry, covering all stages of drug production and quality control.

- 😀 The main objective of GMP is to guarantee that medicines meet the necessary requirements and intended use.

- 😀 The guidelines for GMP are outlined in the 2012 BPOM Regulation (No. HK.00.03.1.3.3.12.1.2.8.195).

- 😀 There are 12 essential aspects of GMP that include quality management, personnel, facilities, and equipment.

- 😀 GMP emphasizes the importance of sanitation and hygiene throughout the production process.

- 😀 Proper documentation is a critical part of ensuring the effectiveness and safety of drug production.

- 😀 Self-inspection and quality audits are necessary for maintaining compliance with GMP standards.

- 😀 Pharmaceutical companies must adhere to GMP regulations to maintain product quality and safety.

- 😀 Institutions involved in the production of radiopharmaceuticals and hospital pharmacies must also implement GMP standards.

- 😀 GMP is periodically updated to reflect new standards and industry needs, ensuring ongoing improvement in pharmaceutical production.

Q & A

What is the purpose of Good Manufacturing Practice (GMP) for drugs?

-The purpose of GMP is to ensure that drugs are consistently produced and controlled to meet the established standards and are suitable for their intended use.

What does the abbreviation 'CPoB' stand for?

-CPoB stands for 'Cara Pembuatan Obat yang Baik', which translates to Good Manufacturing Practice (GMP) for drugs in English.

What are the key aspects of Good Manufacturing Practice (GMP) as outlined in the video?

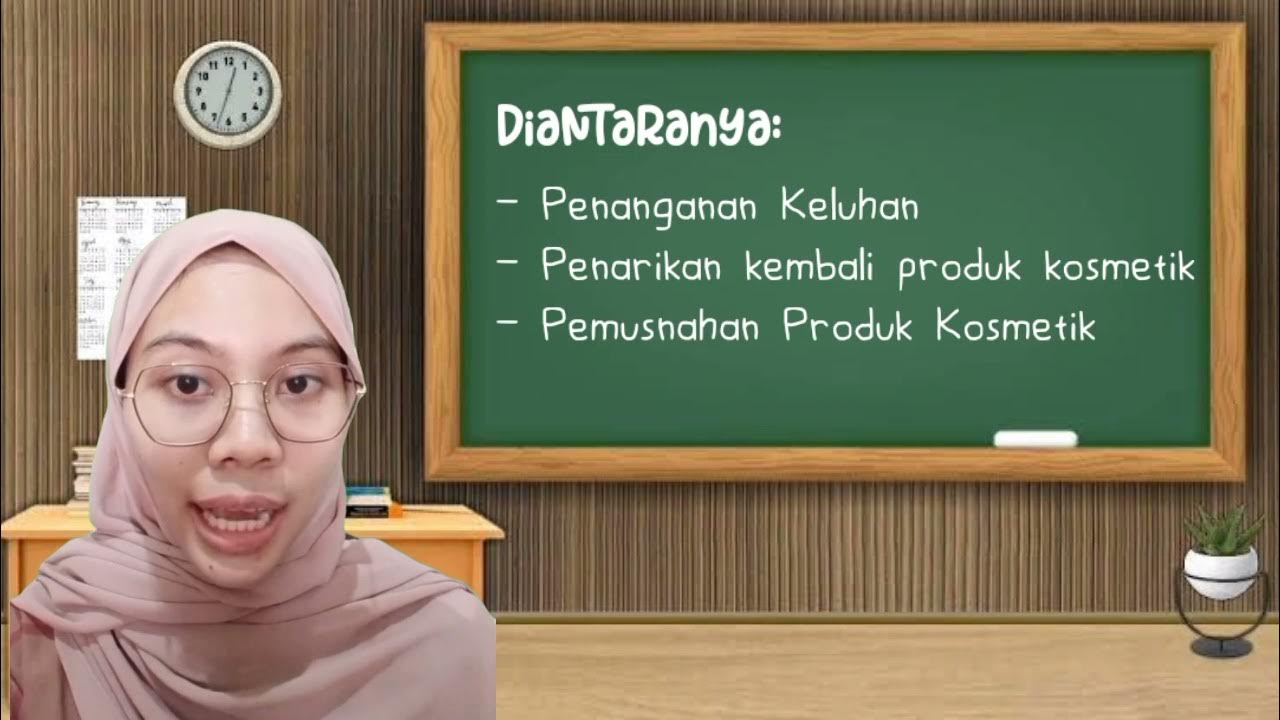

-The 12 key aspects of GMP include: quality management, personnel, buildings and facilities, equipment, sanitation and hygiene, production, quality control, self-inspection, supplier approval, complaint handling, documentation, and qualification/validation.

Who must comply with Good Manufacturing Practice (GMP) standards?

-In addition to pharmaceutical industries, institutions involved in the production of radiopharmaceuticals and pharmaceutical installations in hospitals must also comply with GMP standards.

What does 'BPOM' stand for and what is its role?

-BPOM stands for 'Badan Pengawas Obat dan Makanan' (Food and Drug Supervisory Agency). It is the regulatory authority in Indonesia responsible for enforcing drug regulations, including the establishment of GMP guidelines.

How often are GMP guidelines updated?

-The GMP guidelines are regularly updated, as seen in the video where it is mentioned that the 2012 GMP guidelines may be revised over time to adapt to the latest industry developments.

What is the significance of documentation in GMP?

-Documentation is crucial in GMP because it ensures that all processes and procedures are recorded and traceable. This helps maintain consistency and accountability in drug manufacturing.

What is the role of quality control in drug manufacturing?

-Quality control is responsible for monitoring and ensuring that the drugs produced meet the required standards and specifications to guarantee their safety, efficacy, and quality.

Why is sanitation and hygiene important in drug production?

-Sanitation and hygiene are essential in drug production to prevent contamination, ensuring that the final product is safe for use and meets regulatory requirements.

What does 'self-inspection' refer to in GMP?

-Self-inspection involves internal audits where the organization evaluates its own compliance with GMP standards, ensuring that all procedures are being followed and identifying areas for improvement.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführen5.0 / 5 (0 votes)