Parallel vs. Sequential vs. Compound - Twin Turbo systems explained - Boost School #11

Summary

TLDRThis video explains the mechanics of compound turbo systems, focusing on their advantages in diesel engines. It contrasts compound, parallel, and sequential turbo setups, emphasizing how they manage exhaust energy to boost power and efficiency. The video covers why compound turbos work well for diesel engines, the benefits of lowering exhaust temperatures, and the challenges in optimizing turbo sizing. Viewers will gain insights into why compound turbos are less common in gasoline engines and how they help reduce nitrogen oxide emissions while improving overall engine performance.

Takeaways

- 😀 Compound turbo systems are designed to combine the benefits of both small and large turbos for improved efficiency and performance.

- 😀 In a compound turbo setup, the small turbo spools first at low RPMs, while the large turbo kicks in at higher RPMs, ensuring better power delivery across the RPM range.

- 😀 Heat is a key challenge in compound turbo systems, as increased pressure leads to hotter air, which can cause knock in gasoline engines.

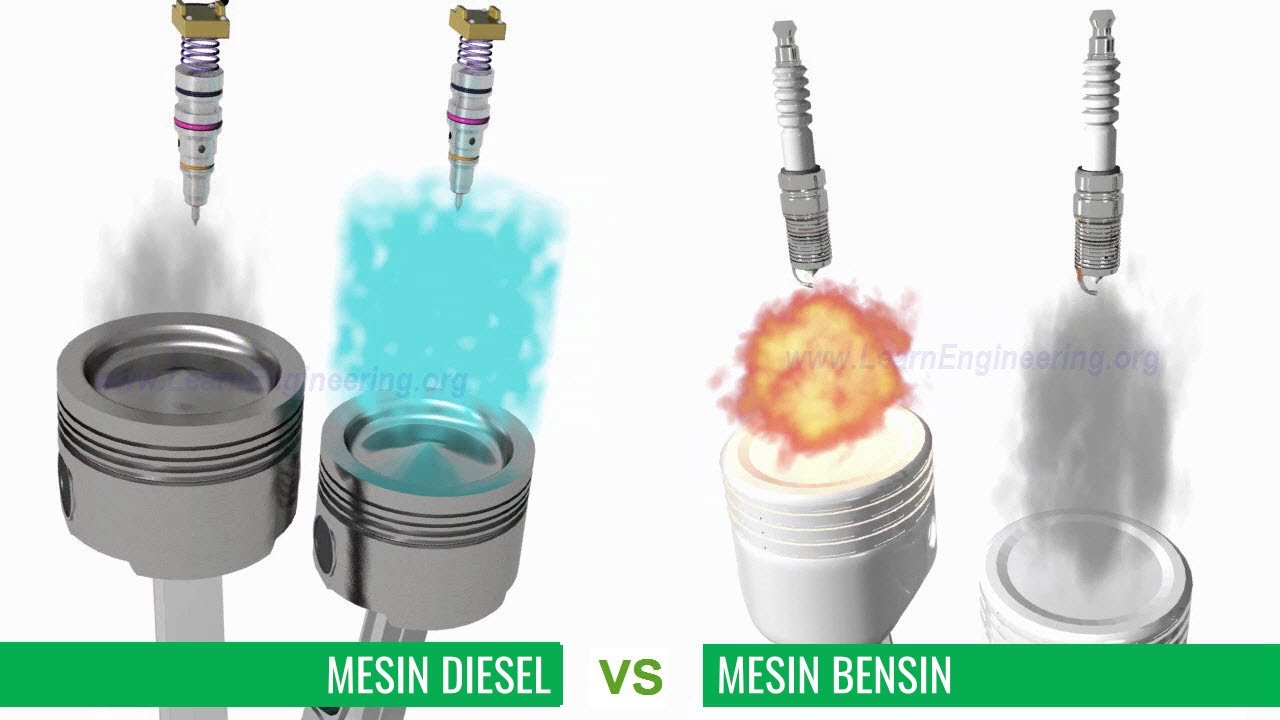

- 😀 Diesel engines are more suited to compound turbo systems because they compress air only, using the heat of the air to ignite the fuel, avoiding knock.

- 😀 Gasoline engines compress both air and fuel, which makes them more susceptible to spontaneous ignition if the air is too hot.

- 😀 A wastegate or exhaust gas control valve directs exhaust gas to the larger turbo once the small turbo has reached its maximum flow capacity, enabling efficient power distribution.

- 😀 Compound turbos are commonly used in diesel engines, both in OEM applications and as aftermarket modifications.

- 😀 Proper turbo sizing is critical for compound systems, as poor sizing can lead to performance losses and inefficiency, sometimes worse than using a single turbo setup.

- 😀 Compound turbo systems help reduce nitrogen oxide emissions in diesel engines by lowering exhaust gas temperatures.

- 😀 Turbo sizing, wastegate control, and exhaust energy distribution are crucial factors in maximizing the efficiency and power of compound turbo systems.

Q & A

What is a compound turbo system and how does it work?

-A compound turbo system involves using two turbos of different sizes. The smaller turbo spools first at low RPMs and handles the lower exhaust gas energy, while the larger turbo kicks in at higher RPMs to provide more boost. The two turbos work in sequence to improve overall performance and efficiency.

Why is compound turbo technology more commonly used in diesel engines than gasoline engines?

-Diesel engines use compression ignition, where the heat from compressed air ignites the fuel. This allows them to handle the increased heat from a compound turbo system without issues. In contrast, gasoline engines mix air and fuel before compression, and excessive heat can cause spontaneous ignition (knock), which is undesirable.

How does increasing pressure in a turbo system affect the air temperature?

-Increasing pressure in a turbo system raises the temperature of the air. In compound systems, the air is typically hotter due to the additional compression, which is why managing heat is crucial, especially in gasoline engines, where excessive heat can lead to engine knock.

What role does the small turbo play in a compound system at low RPM?

-At low RPM, the small turbo is the first to spool up because it is driven by the exhaust gases produced at this stage. It compresses the air and feeds it into the engine. The small turbo handles the lower exhaust energy until the RPM increases enough to engage the larger turbo.

How does the large turbo in a compound system contribute to engine performance at higher RPM?

-As the RPM increases and more exhaust gas is produced, the system opens a wastegate to direct exhaust gases to the larger turbo. The larger turbo then spools up, compresses the incoming air further, and feeds it to the small turbo for additional compression, contributing to more power and efficiency.

Why are compound turbo systems particularly beneficial for diesel engines in terms of emissions?

-Compound turbo systems help lower exhaust gas temperatures, which reduces the formation of nitrogen oxides (NOx). This is particularly important in diesel engines, which are known for producing higher levels of NOx. By lowering exhaust temperatures, compound turbos contribute to cleaner emissions.

What is the importance of turbo sizing in a compound turbo system?

-Turbo sizing is crucial because if the turbos are not properly matched to the engine's needs, the system can underperform. Incorrect turbo sizing can lead to inefficiencies or, in the worst case, worse performance than a single turbo setup.

What does the wastegate do in a compound turbo system?

-The wastegate controls the flow of exhaust gases between the small and large turbos. When the small turbo cannot handle all the exhaust gas at higher RPMs, the wastegate opens to direct some of the exhaust gases to the large turbo, allowing it to spool up and contribute to the system's performance.

Why are compound turbos used in both OEM and aftermarket diesel engines?

-Compound turbos are used in OEM and aftermarket diesel engines because they provide significant performance improvements, including better efficiency, reduced exhaust gas temperatures, and lower NOx emissions. Their ability to handle a wide range of exhaust gas flow makes them a popular choice for performance tuning.

What is the key difference between sequential and compound turbo systems?

-In a sequential turbo system, multiple turbos work in a sequence, with each turbo engaging at different RPM ranges. In contrast, a compound turbo system involves two turbos of different sizes that work together to compress the air more efficiently, with the large turbo supporting the small one as exhaust energy increases.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

El ciclo diésel (cuatro tiempos)

Perbedaan Motor Pembakaran Dalam Dan Motor Pembakaran Luar | BeOto Channel | Video Part 1

ATPL Aircraft General Knowledge - Class 4: Diesel Engines.

Cara Kerja Bosch Pump / Pompa Injeksi INLINE pada Mesin Diesel

Tahanan dan Propulsi - Pengenalan Sistem Propulsi (Pertemuan 1)

Mesin Bensin vs Mesin Diesel

5.0 / 5 (0 votes)