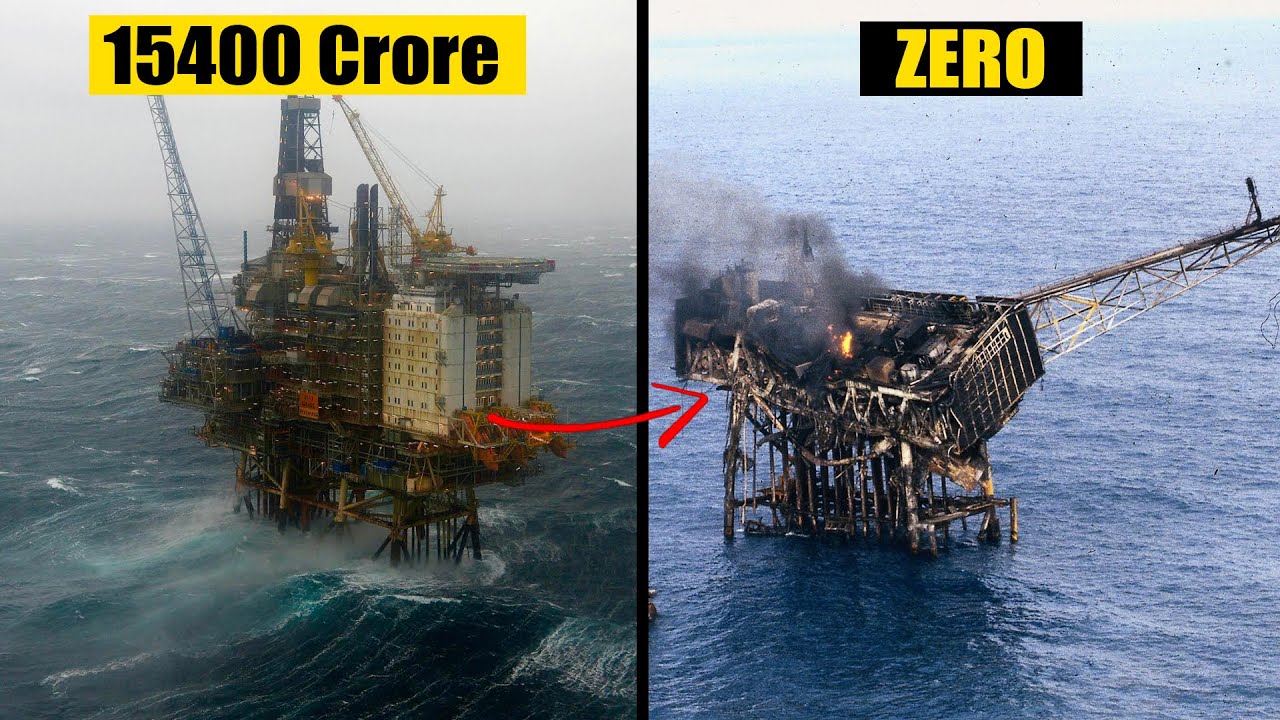

Lesson Learned - Kejadian Piper Alpha

Summary

TLDRThe Piper Alpha disaster, which occurred on July 6, 1988, was one of the deadliest industrial accidents in history, killing 167 people. A series of failures, including poor safety protocols, inadequate design, and miscommunication, led to a massive explosion on the platform. Despite the initial explosion, the lack of proper emergency response and continued oil pumping from nearby rigs worsened the situation. The tragedy prompted widespread reforms in offshore safety, highlighting the critical importance of thorough risk analysis, design integrity, and effective emergency procedures to prevent future disasters.

Takeaways

- 😀 The Piper Alpha platform was a major oil and gas production facility in the North Sea, initially producing 10% of Britain's North Sea oil before the disaster.

- 😀 On July 6, 1988, a catastrophic explosion occurred on the Piper Alpha platform, killing 167 of the 226 men on board, with only 61 survivors.

- 😀 The disaster was caused by a combination of design flaws, poor safety procedures, and inadequate risk management, leading to a chain of events that were hard to control once the explosion began.

- 😀 The platform had inadequate fireproofing and lacked blast walls, which would have helped contain the disaster's escalation.

- 😀 A critical safety failure occurred when a metal plate used to temporarily seal a gas line broke, releasing gas into the platform, which triggered the explosion.

- 😀 Management failed to respond effectively to the emergency, with communication breakdowns and confusion about evacuation protocols exacerbating the situation.

- 😀 Emergency systems, like the automatic fire Deluge system, were ineffective due to incorrect manual overrides, preventing timely firefighting and rescue efforts.

- 😀 Despite warnings about the risks of high-pressure gas pipelines, no action was taken to reinforce them, which led to a gas pipeline rupture that intensified the disaster.

- 😀 Communication between the nearby rigs, Claymore and Tartan, was delayed, and oil continued to flow, worsening the backfire that fueled the explosion.

- 😀 After the explosion, emergency response efforts were disorganized, with some crew members trying to escape by jumping into the sea, but many died from smoke inhalation and fire.

- 😀 The public inquiry following the disaster identified Occidental Petroleum's superficial approach to safety and poor risk management as key factors, leading to significant changes in offshore platform safety regulations.

- 😀 In the aftermath of the inquiry, billions were spent on improving safety measures across the industry, with new safety features implemented on platforms, and regulatory oversight shifted to the Health and Safety Executive.

Q & A

What was the Piper Alpha platform and why was it significant?

-The Piper Alpha platform was a giant oil and gas production facility located 110 miles from Aberdeen in the North Sea. At its peak, it produced 30,000 tons of oil per day and was responsible for 10% of Britain's North Sea oil production. Its massive size made it seem almost indestructible, but it was also flawed in its design and safety measures.

What event occurred on the night of July 6th, 1988, and what caused it?

-On the night of July 6th, 1988, a catastrophic disaster unfolded on the Piper Alpha platform. A gas leak, caused by a combination of faulty permits, maintenance issues, and safety system failures, led to a series of explosions, resulting in the platform being destroyed and the loss of 167 lives.

How did the design of Piper Alpha contribute to the disaster?

-The platform's design, which was adapted to handle both oil and gas extraction, created serious vulnerabilities. Gas compression units were placed close to sensitive areas, such as the control room, and fireproof walls were not adequate to withstand blasts. These design flaws exacerbated the effects of the explosion.

What was the role of the permit-to-work (PTW) system, and how did its failure contribute to the disaster?

-The PTW system was intended to ensure safety during maintenance work by formally approving tasks. However, on the night of the disaster, the PTW system had degraded, with permits being mismanaged and critical information not being communicated. This failure contributed directly to the explosion, as a key valve was removed without proper authorization or communication.

What was the impact of the automatic fire deluge system failure on Piper Alpha?

-The fire deluge system, which was designed to automatically release seawater to extinguish fires, failed because it was switched to manual operation while divers were working on the platform. This failure left the platform vulnerable to the fires that ultimately spread uncontrollably.

How did the explosion and fire spread across the platform?

-The explosion initially caused oil and gas to spill and ignite, but the fire spread rapidly due to the design flaws in the fireproofing of the platform. The explosion ruptured pipes, and the fire eventually spread to key areas, including the oil separation area, making the platform nearly impossible to contain or escape.

What mistakes were made in the response to the disaster?

-Key mistakes in the response included a lack of communication, failure to use the public address system to issue evacuation orders, and confusion regarding how to abandon the platform. Despite the emergency shutdown, the firefighting efforts were uncoordinated, and many crew members were left in the dark about how to escape.

How did neighboring rigs like Tartan and Claymore respond during the disaster?

-Despite hearing distress signals and seeing flames from Piper Alpha, the rigs at Tartan and Claymore continued to pump oil. This decision was made because their managers prioritized production over safety, delaying the shutdown that could have prevented the gas pipelines from rupturing and worsening the fire.

What was the role of the safety vessel Pharos in the disaster?

-The safety vessel Pharos, designed to assist during emergencies, arrived at Piper Alpha but was unable to provide immediate help. The fire hoses were turned on too quickly, triggering a failure in the system, and the gangway took too long to extend, delaying evacuation efforts and ultimately contributing to the disaster's escalation.

What were the long-term changes made in response to the Piper Alpha disaster?

-Following the Piper Alpha disaster, extensive changes were made to improve safety on offshore rigs. These included the installation of emergency shut-off valves, the reinforcement of accommodation blocks, and the transfer of regulatory responsibility to the Health and Safety Executive. The goal was to prevent similar tragedies in the future by improving risk analysis and safety procedures.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

A Brief History of: The Bhopal Gas Tragedy (Short Documentary)

The Secret of Piper Alpha Oil Rig Disaster lies at the Bottom of the Sea

No Crash, but 500 Dead: The Balvano Train Disaster | A Short Documentary | Fascinating Horror

GAS BHOPAL - BENCANA INDUSTRI YANG PALING MENGERIKAN DI INDIA

The Boston Molasses Disaster of 1919

The Triangle Shirtwaist Factory Fire | History

5.0 / 5 (0 votes)