Peach Koehler Equation (Part 1): Glide Force on a Dislocation

Summary

TLDRThis video explains the role of dislocations in plastic deformation, focusing on the Peach-Koehler force. It details how external stress applied to a crystal leads to the motion of dislocations along slip planes, causing permanent shape changes. The work done by external forces is equated to the work on the dislocation, establishing the force per unit length (FL) acting on it. An example involving a positive edge dislocation illustrates these principles, showing how shear stress induces movement via the Burgers vector and how this relates to the overall deformation of the material.

Takeaways

- 😀 The Peach-Koehler force describes the force on a dislocation due to an applied stress field.

- 😀 Plastic deformation in materials is primarily caused by the motion of dislocations along their slip planes.

- 😀 External stresses create a stress tensor that influences dislocation movement.

- 😀 The force per unit length (FL) on a dislocation is critical for understanding its motion.

- 😀 The work done on the dislocation (W_dislocation) must equal the work done by external forces (W_external) acting on the crystal.

- 😀 In the analyzed scenario, a positive edge dislocation is depicted as an upside-down 'T', representing an extra half-plane in the crystal structure.

- 😀 Shear stress (τ) applied to the crystal causes the dislocation to move and results in overall deformation.

- 😀 The Burgers vector (B) represents the displacement caused by dislocation motion within the crystal.

- 😀 The total work done by external forces is expressed in terms of shear stress and the area of the crystal face being acted upon.

- 😀 Equating the works done allows for the derivation of the force per unit length (FL), laying the groundwork for more general dislocation dynamics formulas.

Q & A

What is the primary mechanism of plastic deformation in materials?

-Plastic deformation is primarily caused by the motion of dislocations within a crystal lattice.

What is the Peach-Koehler force?

-The Peach-Koehler force refers to the force acting on a dislocation due to an applied stress field, which drives its motion.

How is the work done on a dislocation calculated?

-The work done on a dislocation is calculated as the product of the force per unit length acting on the dislocation and the displacement it undergoes.

What role does shear stress play in dislocation movement?

-Shear stress applied to a crystal induces movement of dislocations along their slip planes, facilitating plastic deformation.

What is the Burgers vector, and why is it important?

-The Burgers vector is a vector that represents the magnitude and direction of the lattice distortion associated with a dislocation. It is crucial for understanding the slip behavior of dislocations.

How is the external force on a crystal related to its dimensions?

-The external force acting on a crystal is determined by the shear stress and the area of the crystal face affected, often expressed as F_external = 2 * τ * W, where τ is shear stress and W is width.

Why is it necessary to equate the work done on the dislocation to the work done by external forces?

-Equating the work done allows us to derive relationships that describe the behavior of dislocations under stress, ensuring that energy is conserved in the deformation process.

What is the significance of the force per unit length on a dislocation?

-The force per unit length on a dislocation, denoted as F_L, is significant as it directly influences the dislocation's movement and, consequently, the material's plastic deformation characteristics.

What does the equation F_L = (2τB)/L signify?

-This equation signifies the relationship between the force per unit length on a dislocation, the applied shear stress (τ), the Burgers vector (B), and the length of the dislocation line (L).

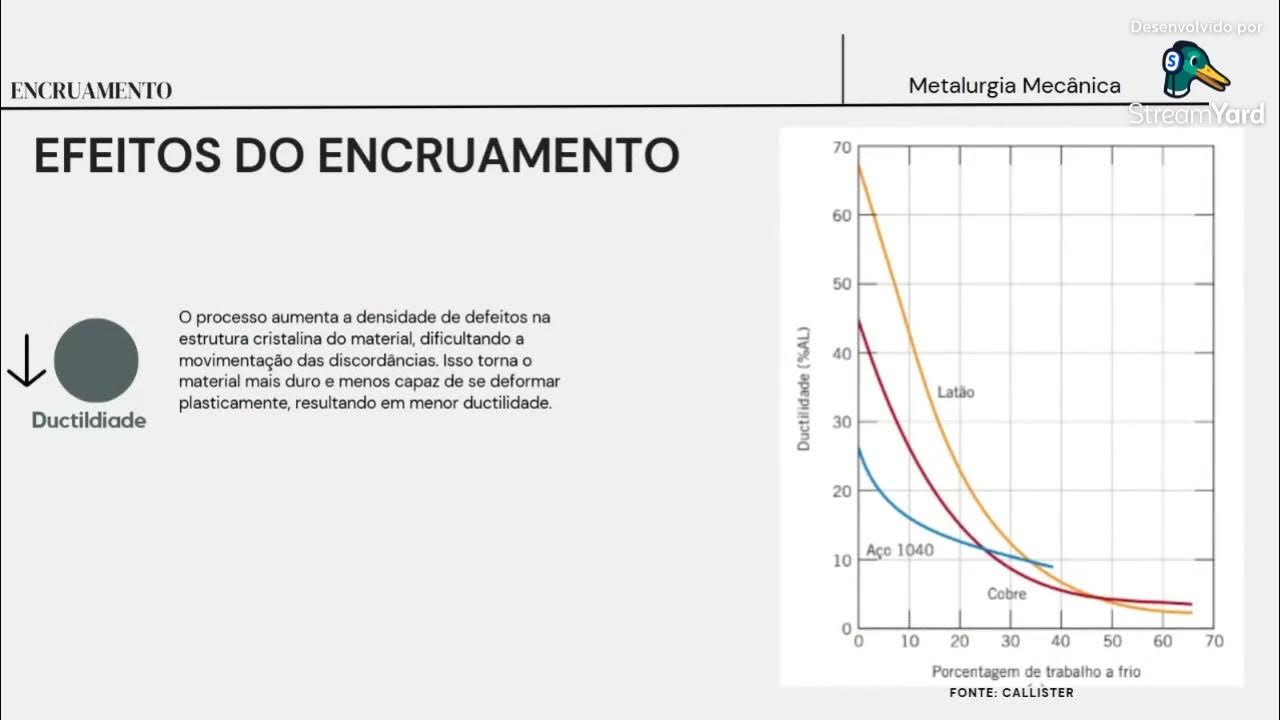

How does the movement of dislocations affect the mechanical properties of materials?

-The movement of dislocations affects mechanical properties such as strength, ductility, and toughness, as dislocation activity is crucial for how materials respond to applied stresses.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführen5.0 / 5 (0 votes)