Auxiliary Marine Boiler is use for?

Summary

TLDRThe video discusses the use of marine boilers on ships, primarily for auxiliary purposes rather than propulsion. It explains the two main types of boilers: water tube and fire tube. The auxiliary boilers generate steam for various functions, such as heating heavy fuel oil to reduce viscosity for easier flow, purifying fuel and lube oil, maintaining engine jacket water temperatures when the main engine is inactive, and heating accommodation in cold weather. Steam is critical for efficient ship operations and maintaining engine performance, especially in challenging conditions.

Takeaways

- ⚓ Marine boilers are mostly used for auxiliary purposes in ships today.

- 🚢 Historically, boilers were part of the main propulsion system, but now steam turbines are mostly found in high-speed vessels used by navies.

- 🔧 Merchant ships now rely on main engines for propulsion, and boilers are auxiliary machinery for steam generation.

- 🔥 There are two types of boilers: water tube boilers (where water flows through tubes surrounded by hot gases) and fire tube boilers (where hot gases flow through tubes submerged in water).

- 💧 Boilers produce steam primarily for ship operations, including heating heavy fuel oil (HFO) for easy flow and transfer.

- 🏭 Heavy fuel oil (HFO) in storage tanks is dense and viscous, and steam from the boiler is used to heat the fuel for proper flow.

- 🛢️ Steam is used to heat both fuel oil and lube oil before they enter purifiers, improving purification efficiency by reducing oil viscosity.

- 🛠️ Boilers help maintain jacket water temperature when the main engine is idle, preventing cold corrosion and thermal stresses during engine startup.

- ❄️ In cold weather, steam from the boiler is used to heat accommodation spaces onboard ships.

- 🌡️ The main engine's temperature must be maintained between 75-78°C when inactive to ensure smooth operation, with boilers assisting in this process.

Q & A

What are the main purposes of marine boilers on ships today?

-Marine boilers are mostly used for auxiliary purposes, such as producing steam for heating and other machinery functions, rather than for propulsion.

How did the role of boilers change from past to present on ships?

-In the past, boilers were part of the main propulsion system, but today they are primarily used for auxiliary functions, as most ships are powered by diesel engines.

What types of ships still use steam turbines, and why?

-Steam turbines are mostly found in high-speed vessels used by navies, while merchant ships have switched to main diesel engines for propulsion.

What are the two types of boilers commonly used on ships, and how do they work?

-The two types of boilers are water tube boilers and fire tube boilers. In water tube boilers, water flows through tubes surrounded by hot gases, while in fire tube boilers, hot gases flow through tubes submerged in water.

Why is heavy fuel oil (HFO) stored in tanks heated on ships?

-Heavy fuel oil is very viscous, almost like tar, and must be heated to lower its viscosity for easier flow and transfer between storage and service tanks.

How is steam from the auxiliary boiler used in the purification of fuel and lube oil?

-Steam heats the oil before it enters the purifier, reducing its viscosity to improve the purification process.

Why is it important to maintain the jacket water temperature in the main engine when it is not in operation?

-Maintaining the jacket water temperature between 75 to 78°C prevents cold corrosion and thermal stresses when the engine is restarted.

How is the main engine’s jacket water temperature maintained when the engine is at standby or in port?

-A pre-heater, either using steam from the boiler or an electrical heater, is used to keep the engine's temperature stable when it’s not in use.

How does the boiler help in cold weather conditions on the ship?

-In cold weather, the boiler produces steam that is used to heat the accommodation areas of the ship.

Why is controlling the viscosity of heavy fuel oil important on ships?

-Controlling the viscosity is crucial for ensuring that the fuel can flow easily through the fuel system and be used efficiently by the engines.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Tahanan dan Propulsi - Pengenalan Sistem Propulsi (Pertemuan 1)

Practical Marine Electrical Knowledge: Program 8. Electric Propulsion & High Voltage Practice

Ketel Uap di Kapal Niaga (Part 4) - Lilin Tua #belajarbersama #mesin #kapal #lilintua #engineer

Headway 5th Edition Upper-Intermediate I Unit 5 Robothespian |

Milestone 6 presentation

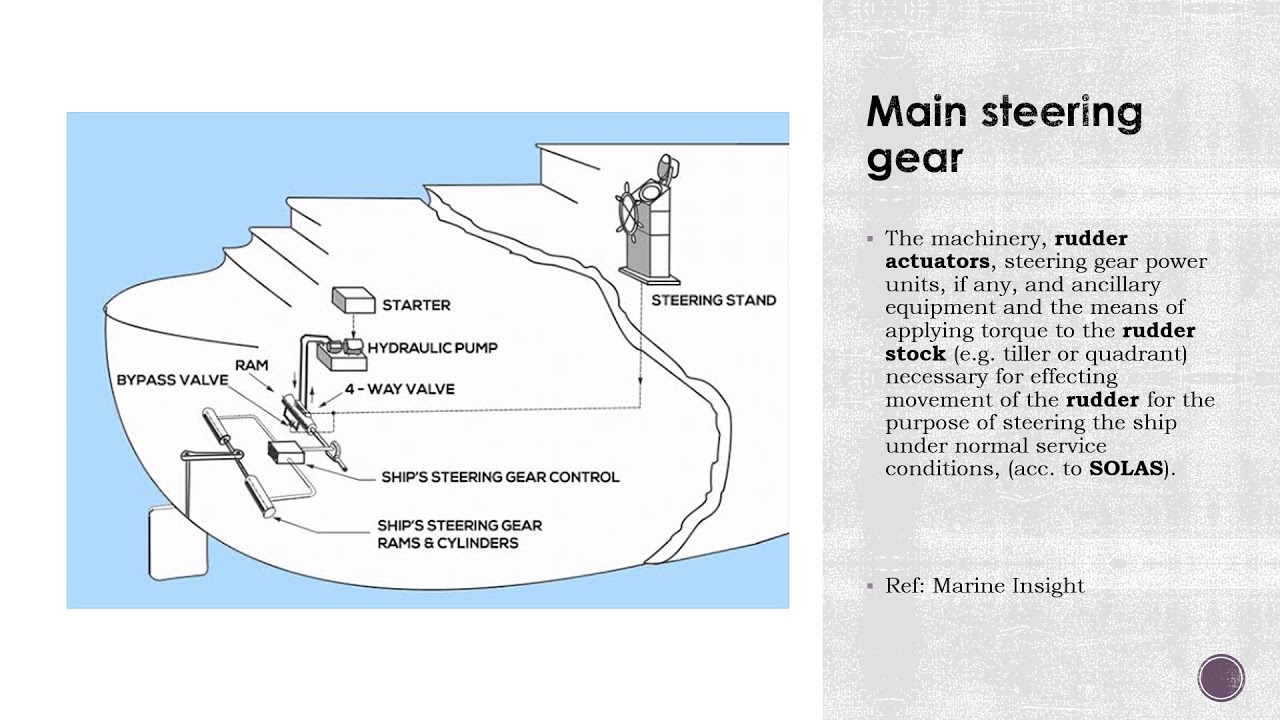

Different types of Steering Gears found on ships

5.0 / 5 (0 votes)