Can I make Titanium Damascus?

Summary

TLDRIn this video, the creator revisits a six-year-old idea of making titanium Damascus after discovering that the patent for the process expired in February 2023. The video documents the technical challenges of welding titanium using inert gas purging, dealing with different titanium grades, and experimenting with the Forge temperature. Despite setbacks like overheating and a melted billet, the attempt is successful, producing striking titanium Damascus with vibrant colors. The creator hints at future experiments, including titanium Mosaic Damascus, and encourages viewers to explore their website for more updates.

Takeaways

- 🔧 The video creator has been interested in making titanium Damascus but previously held back due to a patent on forge welding titanium laminates, which has now expired.

- 📅 The relevant patent expired in February 2023, freeing the creator to experiment with making titanium Damascus without legal concerns.

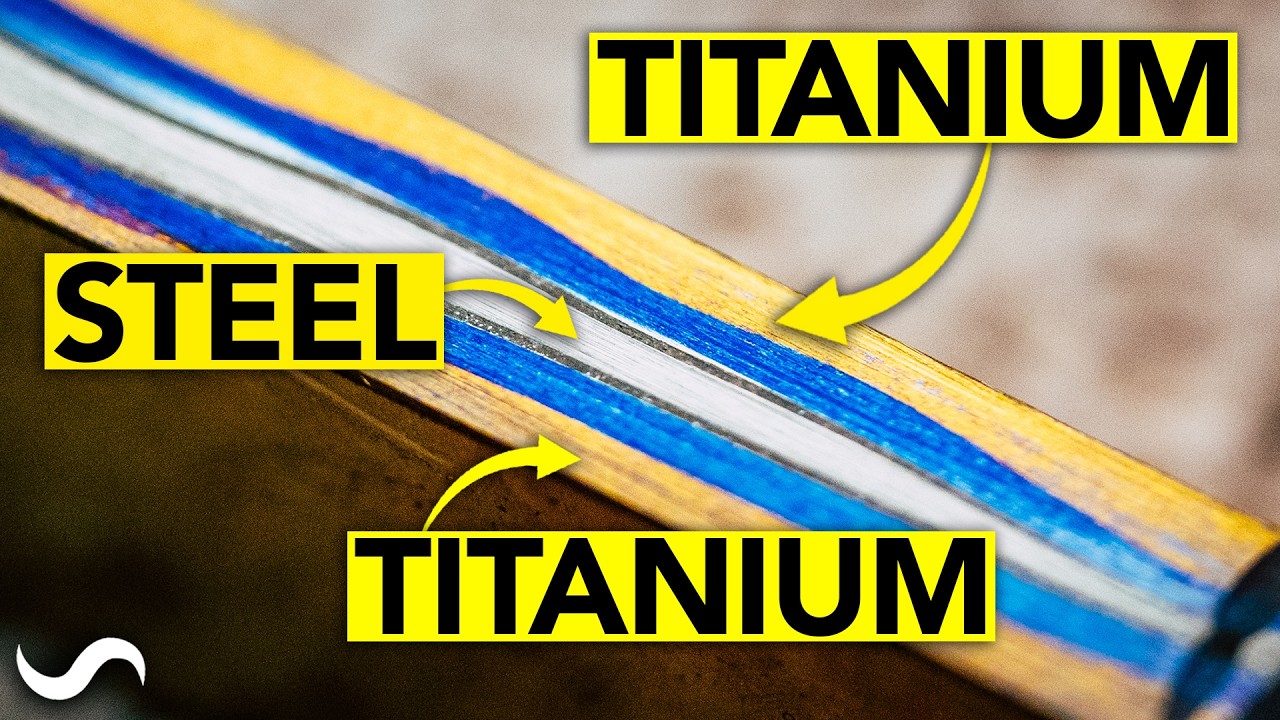

- 🧪 Titanium Damascus involves using various grades of titanium, specifically CP (commercially pure) and grade 5 (6Al 4V).

- 📦 The process requires creating a steel box (canister) for the titanium pieces and purging it with inert gas (argon) to avoid contamination during heating.

- 🛠️ Purging the canister with argon is crucial, as it prevents oxygen and nitrogen from interacting with the titanium during the forge welding process.

- 🔥 The titanium billets need to be heated between 1,700 and 2,000°F, but overheating can lead to melted or damaged titanium.

- 💰 The experiment is costly, with the materials alone costing around £500 or $700, making it important to handle the process carefully.

- 🎨 One of the unique features of titanium Damascus is its ability to display vibrant colors through the oxidation process without the need for acid etching.

- 🤯 Despite some challenges and mistakes during the process, the creator successfully managed to create a piece of titanium Damascus with distinct layers.

- 🚀 The video hints at future plans to explore more complex patterns, such as titanium mosaic Damascus and experimenting with other metals using the inert gas technique.

Q & A

What was holding the speaker back from making titanium Damascus initially?

-The speaker was hesitant to make titanium Damascus due to an active United States patent for forge welding laminates of titanium and titanium alloys. They didn't want to run afoul of the patent and risk legal issues.

What discovery prompted the speaker to revisit titanium Damascus?

-The speaker’s colleague Jamie discovered that the patent for forge welding titanium and titanium alloys had expired in February 2023, allowing them to attempt making titanium Damascus without fear of legal repercussions.

What types of titanium are being used in the experiment?

-The speaker is using two types of titanium: grade two (commercially pure titanium) and grade five (an alloy containing 6% aluminum and 4% vanadium, also known as 6 Al 4V).

What is the purpose of the 'can' mentioned in the script?

-The can, made from mild steel, is used to contain the different grades of titanium during the forge welding process. It also has holes to allow for an inert gas purge, preventing oxidation.

Why is argon gas used in this process?

-Argon gas, an inert gas, is used to purge the container of oxygen and nitrogen while the titanium heats. This prevents the titanium from oxidizing during the forge welding process.

What mistake did the speaker make when creating the initial steel box for the titanium?

-The speaker assumed the dimensions of the steel were 50 mm when in fact it was 51 mm, causing the titanium pieces not to fit. This led to a remake of the box.

What is the importance of cleanliness in this process?

-It is crucial that all materials, especially the titanium, are free of oxides, oil, dirt, and debris. Cleanliness is even more important than when making steel Damascus, as titanium is much more expensive and sensitive.

What temperature range is ideal for forge welding titanium Damascus, according to the patent?

-The ideal temperature range for forge welding titanium Damascus is between 1,700°F and 2,000°F. This range allows the titanium to bond without risking molten titanium explosions.

What happened during the first heating attempt?

-During the first heating attempt, the temperature exceeded the target, reaching 2,100°F, which resulted in overheating and partially melting the titanium billet.

What is special about titanium Damascus compared to steel Damascus?

-Titanium Damascus is unique because it produces vibrant colors like purples and blues through oxidation alone, without the need for acid etching. These colors form due to the different grades of titanium oxidizing in distinct ways, which cannot be replicated with steel to the same degree.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

5.0 / 5 (0 votes)