ultrasonic testing

Summary

TLDRThis media explains ultrasonic testing, a technique used to detect internal flaws in materials by transmitting high-frequency sound pulses through the specimen. It can inspect materials up to 30 feet in length, including welds. The system involves a pulser, transducer, and display. Sound waves reflect off defects, and these reflections are converted into signals that show defect size, position, and type. Advantages include portability and automation, while a key disadvantage is difficulty inspecting coarse-grained materials like cast iron due to low sound transmission and noise.

Takeaways

- 🔊 Ultrasonic testing is used to detect internal flaws by sending high-frequency sound pulses through the specimen.

- 📏 It can test thickness and lengths up to 30 feet, making it suitable for large structures.

- 🔧 Ultrasonic testing is also used to inspect welds for defects.

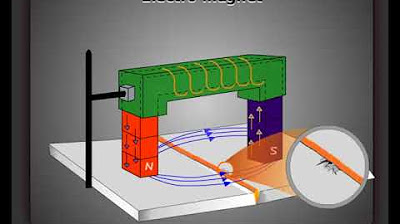

- ⚙️ An ultrasonic system is composed of a pulser, a transducer, and display devices.

- 💡 The pulser generates high-voltage electric pulses that drive the transducer.

- 🎛️ The transducer produces high-frequency ultrasonic energy that is directed onto the specimen.

- 🔄 When a sound wave encounters a crack or defect, it is reflected back and turned into an electrical signal by the transducer.

- 📊 The reflected signal, shown on the display, indicates the position, size, and type of defects in the specimen.

- 🚚 One advantage of ultrasonic testing is that it's portable and can be fully automated.

- ❌ A disadvantage is that it struggles with coarse-grained materials like cast iron due to low sound transmission and high signal noise.

Q & A

What is ultrasonic testing used for?

-Ultrasonic testing is used to determine internal flaws in materials by passing high-frequency sound pulses through the specimen.

What types of materials can be tested using ultrasonic testing?

-Ultrasonic testing is used on a variety of materials to detect flaws, but cast iron and other coarse-grained materials are harder to inspect due to low sound transmission and high signal noise.

How does ultrasonic testing detect internal defects in a material?

-High-frequency sound pulses are directed at the specimen. When the sound wave encounters a defect, it is reflected back, and the reflected signal is then converted into an electrical signal and displayed on a screen.

What is the role of the pulser in an ultrasonic system?

-The pulser generates high-voltage electrical pulses that drive the transducer, which in turn produces high-frequency ultrasonic energy.

What happens when the transducer encounters a defect in the specimen?

-When the transducer encounters a defect, the sound wave is reflected back. The transducer converts this reflected wave into an electrical signal, which is then displayed, showing the location and size of the defect.

What are the main components of an ultrasonic testing system?

-An ultrasonic testing system typically consists of a pulser, a transducer, and a display device.

What is one of the main advantages of ultrasonic testing?

-One main advantage of ultrasonic testing is that it is portable and can be fully automated.

What is the main disadvantage of ultrasonic testing?

-The main disadvantage of ultrasonic testing is that materials like cast iron, with coarse grains, are difficult to inspect due to low sound transmission and high signal noise.

How is the position, size, and type of defects determined in ultrasonic testing?

-The position, size, and type of defects are determined by analyzing the intensity of the reflected sound wave and any distortions in the signal.

What is the maximum thickness and length of a specimen that can be tested using ultrasonic testing?

-Specimens with a thickness and length of up to 30 feet can be tested using ultrasonic testing.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführen5.0 / 5 (0 votes)