10 Common Mistakes DIYers Make In Circuit Breaker Boxes

Summary

TLDRThis video script discusses 10 common electrical mistakes DIY enthusiasts make with circuit breakers and panels. It provides solutions for each, emphasizing safety and proper practices like legible labeling, avoiding overloading, protecting wire sheathing, balancing breaker amperage with wire gauge, proper grounding, avoiding wire doubling, using correct wire colors, double-tapped breakers, filler plates, and correct screw torquing. Bonus advice includes maintaining organized wiring to prevent future issues.

Takeaways

- 📝 Always label your electrical panel clearly and legibly to avoid confusion and ensure safety.

- ⚡️ Test your receptacles and switches to ensure no current is running through them before working on the electrical panel.

- 🔌 Avoid overloading your circuit breaker panel by not exceeding 80% of its total amperage capacity.

- 🛠 Protect the sheathing of wires inside the panel to prevent shorts or faults caused by rubbing against the knockouts.

- ⚙️ Ensure a proper balance between circuit breaker amperage and wire gauge to prevent overheating and potential fires.

- ⚡️ Proper grounding is crucial; never cut the main ground wire and avoid improper connections that could lead to electrical issues.

- 🔩 Avoid doubling up on wiring within the same hole on the bus bar to prevent poor connections and potential arcing.

- 🏗️ Use the correct sheathing color for wires as per the National Electric Code: white or gray for neutrals, green or bare for grounds, and typically black or red for hot wires.

- 🚫 Do not double tap circuit breakers unless the manufacturer's specifications explicitly allow for it, as it can lead to troubleshooting difficulties.

- 🧩 Fill all unused knockouts in your circuit breaker panel with filler plates to prevent accidental contact with live parts.

- 🔩 Torque all screws and lugs to the correct tension as specified by the manufacturer to ensure secure and safe connections.

Q & A

What is the first mistake DIY-ers often make with their electrical panels?

-The first mistake is having illegible labels or descriptions in the electrical panel, which can lead to confusion and safety issues.

How can one identify which circuit breaker controls a specific outlet or switch?

-One can use a circuit breaker finder tool, which is plugged into an outlet and then used to identify the correct breaker by running it over each one.

What is the recommended maximum percentage of amperage usage for a circuit breaker panel?

-It is recommended to use no more than 80% of the panel's total amperage capacity to avoid overloading.

Why is it important to protect the sheathing of the wires inside the electrical panel?

-Protecting the sheathing prevents the wires from rubbing against the knockouts inside the panel, which could cause the sheathing to wear down and lead to shorts or faults.

What should one do if they are unsure about working on their electrical panel?

-If there is any uncertainty or lack of confidence in handling electrical panel work, it is advisable to call a professional electrician.

Why is it crucial to match the wire gauge with the amperage of the circuit breaker?

-Matching the wire gauge with the circuit breaker amperage ensures that the wire can safely handle the amount of electricity flowing through it, preventing overheating and potential fires.

What are the common mistakes made regarding grounding in electrical panels?

-Common mistakes include cutting the main ground wire, twisting multiple ground wires together without proper connection to the bus bar, and not ensuring all components are properly grounded.

Why should one avoid doubling up on wiring within the same hole on the bus bar?

-Doubling up increases the risk of a poor connection, which could lead to arcing, sparking, or other electrical issues.

What is the significance of using the correct sheathing color for wires in electrical panels?

-Using the correct sheathing color (white or gray for neutrals, green or bare for grounds, and typically black or red for hot wires) helps in easily identifying the function of each wire and adhering to the National Electric Code.

What is 'double tapping' in the context of circuit breakers and why is it sometimes a problem?

-Double tapping refers to connecting two different wires to the same circuit breaker, which can be against code and may complicate troubleshooting due to the shared nature of the circuit.

Why are filler plates important in a circuit breaker panel?

-Filler plates are important to cover any unused knockouts in the panel to prevent accidental contact with live parts and to maintain safety standards.

How does one ensure that the screws and lugs in an electrical panel are tightened to the correct tension?

-One should use a torque screwdriver to apply the correct amount of pressure as specified by the manufacturer, which is typically indicated on the inside of the panel or the circuit breaker itself.

What is the bonus tip provided at the end of the script regarding electrical panel wiring?

-The bonus tip is to avoid creating a tangled 'rat's nest' of wires in the panel, as this can make it difficult to identify and work with individual wires, potentially leading to accidents or mistakes.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Phân tích và vẽ sơ đồ nguyên lý tổng thể tòa nhà - Phần 1

Types of Circuit Breaker with Detailed Classifications | TheElectricalGuy

Avoid These 5 DIY Electrical Mistakes

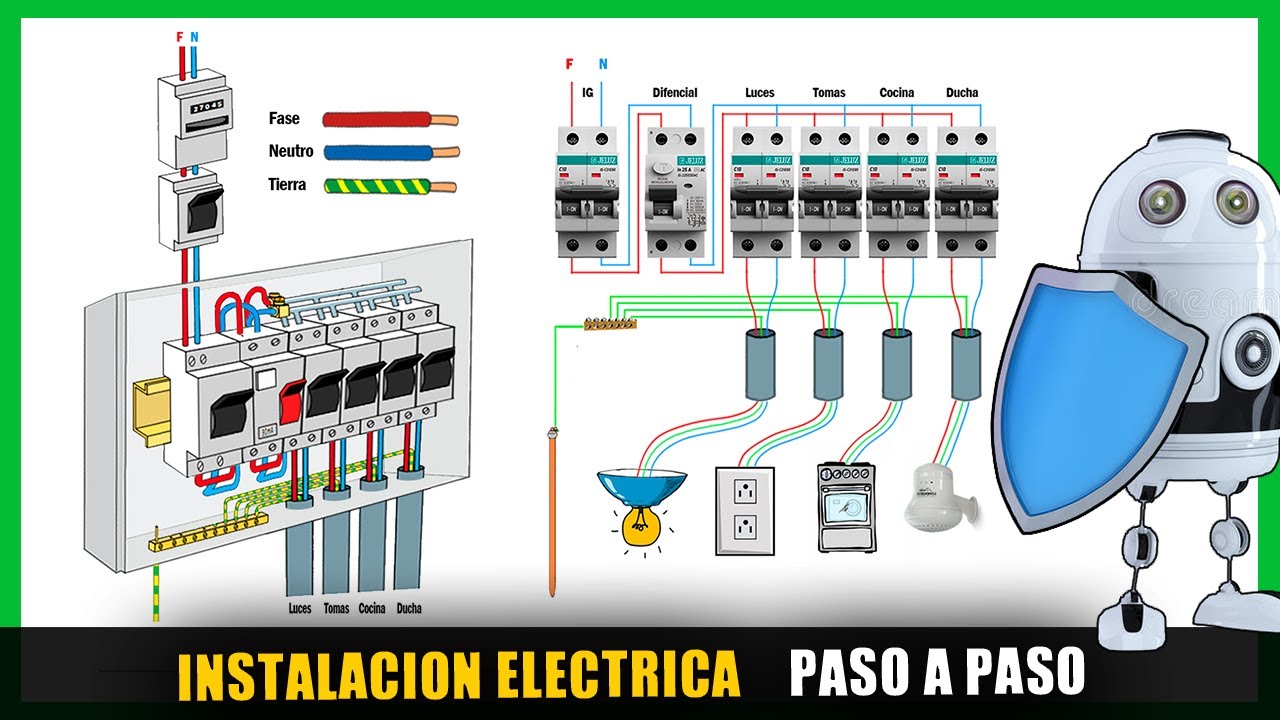

INSTALACION ELECTRICA de una casa paso a paso, como armar el TABLERO ELECTRICO

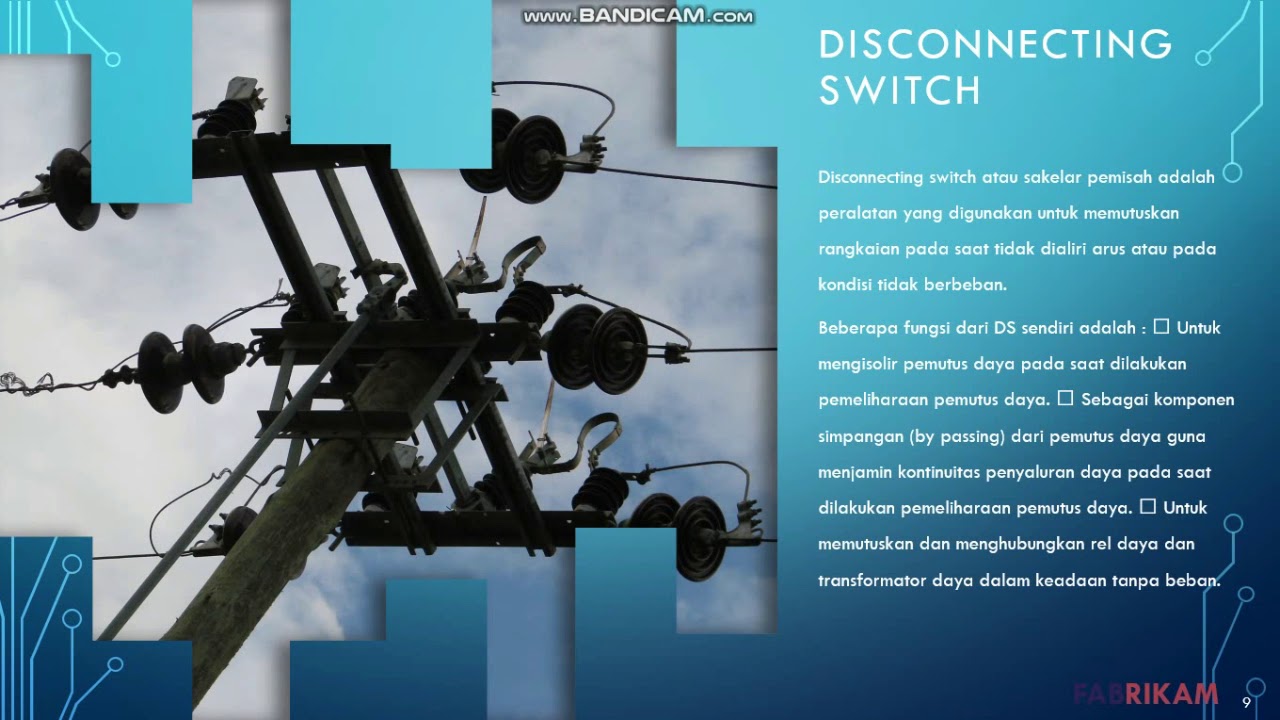

20 Jenis peralatan distribusi listrik

RESIDENTIAL ELECTRICAL MATERIALS Apprentice Electricians Should Know

5.0 / 5 (0 votes)