This 3D Bioprinted Organ Just Took Its First "Breath"

Summary

TLDRResearchers have developed a 3D bioprinted lung-mimicking air sac using living cells, marking a significant step towards replicating human organs to avoid rejection. The model, smaller than a penny, demonstrates the potential of 3D bioprinting to create complex organ structures. The team overcame challenges in printing independent vessel architectures with an open-source SLATE technology, using food dye to control light-induced solidification. This breakthrough could address the organ shortage, with the team making their designs freely available to foster further scientific advancements.

Takeaways

- 💡 Scientists have created a 3D bioprinted lung-mimicking air sac using living cells, which is a significant step towards replicating human organs.

- 🔍 The lung model is smaller than a penny but demonstrates the potential to avoid organ rejection by using a patient's own cells.

- 🏗️ The team aims to replicate the complex structures of human organs, starting with the lung as a proof of concept.

- 🌡️ The lung model can mimic blood flow and ventilate oxygen, providing insights into how red blood cells take up oxygen.

- 🌟 Printing multiple independent vessel architectures is a major challenge due to the intricate vascular networks in organs.

- 👨⚕️ The liver is highlighted as an example of an organ with over 500 functions, all dependent on its complex vascular network.

- 🔑 The potential of bioprinting to address the shortage of organs for over 100,000 people in the U.S. is emphasized.

- 🧬 Bioprinted organs could reduce organ rejection rates as they would contain the patient's own cells.

- 🧪 Living cells are fragile and require quick placement into a hydrogel environment to ensure survival after extraction.

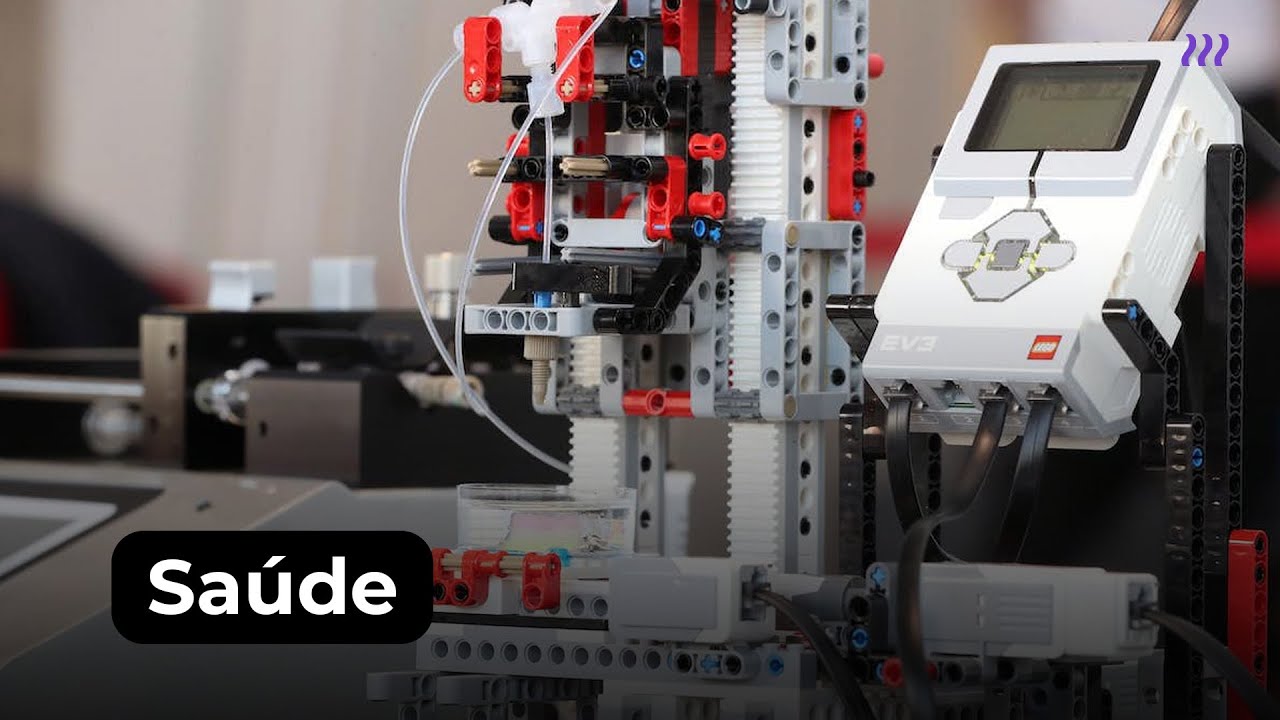

- 🛠️ The team used a technique called SLATE (Stereolithography Apparatus for Tissue Engineering) for creating the lung model.

- 💡 Food dye was discovered as a biocompatible material to block light and enable the creation of complex internal structures in the hydrogel.

- 📚 The team has made their source data freely available to promote collaboration and further research in the field of 3D bioprinting.

Q & A

What is the purpose of the 3D bioprinted lung-mimicking air sac?

-The 3D bioprinted lung-mimicking air sac is designed to replicate the functions of a human lung, including pumping air into airways and mimicking blood flow, using living cells. It serves as a proof of concept for the potential of 3D bioprinting to replicate human organs and potentially avoid organ rejection.

How does the lung-mimicking air sac contribute to the field of organ replication?

-The lung-mimicking air sac brings researchers one step closer to understanding how to replicate human organs using a patient's own cells, which could help to avoid organ rejection and address the shortage of available organs for transplant.

What is the significance of the team's approach to replicating the architectural structures of human organs?

-Replicating the complex architectural structures of organs is crucial because these structures are responsible for the organs' functions. The team's approach using 3D bioprinting and the lung as a proof of concept demonstrates the potential for creating functional artificial organs.

What is the challenge in printing multiple independent vessel architectures in artificial organs?

-The challenge lies in the complexity of organs, where each tissue has its own intricate network of blood vessels that are physically and biochemically intertwined, serving crucial purposes in supplying organs with essential nutrients.

How does the liver illustrate the complexity of organ functions and their dependence on the vascular network?

-The liver, with over 500 functions including bile production for digestion and blood sugar regulation, exemplifies the complexity of organs and how their functions rely on the intricate network of vessels for the necessary nutrients.

What is the current situation regarding the shortage of organs for transplantation in the U.S.?

-Over 100,000 people are waiting for organs in the U.S., highlighting the urgent need for solutions like bioprinting healthy organs to address this shortage.

How do bioprinted organs potentially reduce the incidents of organ rejection?

-Bioprinted organs could reduce organ rejection incidents since they would be created using the patient's own cells, thus minimizing the immune system's response against the transplanted organ.

What is the process of encapsulating living cells within a hydrogel in the context of 3D bioprinting?

-Living cells are extremely fragile outside the body and need to be placed into their final structure quickly. They are encapsulated within a hydrogel, a water-based material that emulates a cell's environment, allowing them to survive for longer periods.

What is the SLATE technique used by Jordan and his team to print the lung model?

-SLATE, or Stereolithography Apparatus for Tissue Engineering, is an open-source bioprinting technology that uses additive manufacturing to create soft hydrogels layer-by-layer using light from a digital projector, allowing for the creation of complex internal structures.

How did the team address the issue of light disrupting the intended pattern during the bioprinting process?

-The team used biocompatible food dyes as a light-blocking element to confine the solidification process to a thin layer, ensuring the creation of the desired internal structures without light interference from previously solidified layers.

What is the significance of the team's decision to make their work's source data freely available?

-By making their work's source data freely available, the team is embracing the open-source philosophy, which encourages collaboration and innovation. This approach can lead to unexpected advancements in the field of 3D bioprinting and organ replication.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآن5.0 / 5 (0 votes)