EVERYTHING on Axial Loading Normal Stress in 10 MINUTES - Mechanics of Materials

Summary

TLDRThis video explains the importance of understanding stresses and strains in materials beyond simply calculating internal forces. It highlights how the same load affects different materials and geometries differently, using examples like plastic versus metal forks. Focusing on axial loading, the video defines normal stress and strain, introduces material properties such as yield and ultimate strength, and distinguishes engineering from true stress and strain. A practical example with an aluminum two-member structure demonstrates how to calculate internal forces, determine stress type (tensile or compressive), and assess whether the member deforms elastically, plastically, or fails. This foundational knowledge is essential for analyzing real-world engineering structures.

Takeaways

- 😀 The need to define stresses and strains in structural analysis comes from the fact that forces can affect different materials differently, depending on their geometry and material properties.

- 😀 For example, the same bending force can easily bend a plastic fork but barely affect a metal one, illustrating how material properties influence deformation.

- 😀 Strain and deformation are not solely dependent on force; material properties and geometry must also be considered.

- 😀 A material like metal may break before reaching the same deflection as a plastic fork under the same load, highlighting the importance of stress over just load.

- 😀 The mechanics of materials course focuses on understanding how to calculate stresses for different types of loading: axial, torsion, bending, and shear.

- 😀 Normal stresses, caused by axial loading, are defined as the force per unit area and are either tensile (positive) or compressive (negative) depending on whether the load elongates or compresses the material.

- 😀 The sign of the load does not determine if the stress is tensile or compressive; this depends on the frame of reference and coordinate system setup.

- 😀 Normal strain is the ratio of deformation to the original length, represented by the Greek letter epsilon.

- 😀 Yield strength is the stress at which a material starts to deform plastically, while ultimate strength is the maximum stress before failure.

- 😀 Engineering stress and strain are commonly used in applications, where engineering stress is based on the initial area before deformation and engineering strain is based on the original length.

- 😀 True stress and true strain account for instantaneous changes in area and length, respectively, and are typically higher than engineering values as deformation occurs.

Q & A

Why is it necessary to define stresses and strains instead of just calculating internal forces?

-Because the same force can produce very different deformations in different materials and geometries. Stresses and strains account for both the material properties and geometry, enabling meaningful predictions and comparisons of structural behavior.

What are the four main types of loading considered in mechanics of materials?

-The four main types are axial loading, torsion, bending, and transverse shear.

How is normal stress defined and what does the term 'normal' mean?

-Normal stress (σ) is defined as the axial load divided by the cross-sectional area, σ = P/A. The term 'normal' refers to the stress being perpendicular to the cross-sectional surface.

What is the difference between tensile and compressive stresses?

-Tensile stress is positive and tries to elongate a member, while compressive stress is negative and tries to shorten or compress the member.

How is normal strain defined and what symbol is used for it?

-Normal strain (ε) is defined as the ratio of deformation (ΔL) to the original length (L0) of a member, ε = ΔL / L0. The Greek letter epsilon (ε) is used to represent strain.

What is the elastic modulus and how is it related to stress and strain?

-The elastic modulus (E) is the ratio of stress to strain in the linear (elastic) region of a material's stress-strain curve, representing the stiffness of the material: E = σ / ε.

What are yield strength and ultimate strength?

-Yield strength is the stress at which a material begins to deform plastically (permanent deformation), typically at 0.2% strain. Ultimate strength is the maximum stress a material can withstand before breaking.

What is the difference between engineering stress/strain and true stress/strain?

-Engineering stress and strain use the initial area and length of the specimen, while true stress and strain account for the instantaneous area and length as the material deforms. True values are generally higher than engineering values.

In the example with aluminum members AB and BC, how is the internal force in member AB determined?

-By drawing a free-body diagram of pin B, assuming directions for the forces, and applying equilibrium equations (sum of forces in x and y directions equal zero), the internal force in member AB is calculated as 45 kN.

How is the stress type (tensile or compressive) determined from the internal force?

-By analyzing the direction of the internal force relative to the member. If the force acts to elongate the member, the stress is tensile; if it acts to shorten the member, the stress is compressive. In the example, member AB is under compressive stress, so σ = -10 MPa.

Why is the stress in member AB considered elastic in the example?

-Because the calculated stress (10 MPa) is lower than the aluminum yield strength (276 MPa), meaning the member deforms elastically and will return to its original shape when the load is removed.

Why is it important to properly draw free-body diagrams for members subjected to axial loads?

-Free-body diagrams help accurately determine the magnitude and direction of internal forces, which is essential for calculating stresses and identifying whether the member experiences tension or compression.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

Aprenda agora o que é tensão na resistência dos materiais (ResMat)

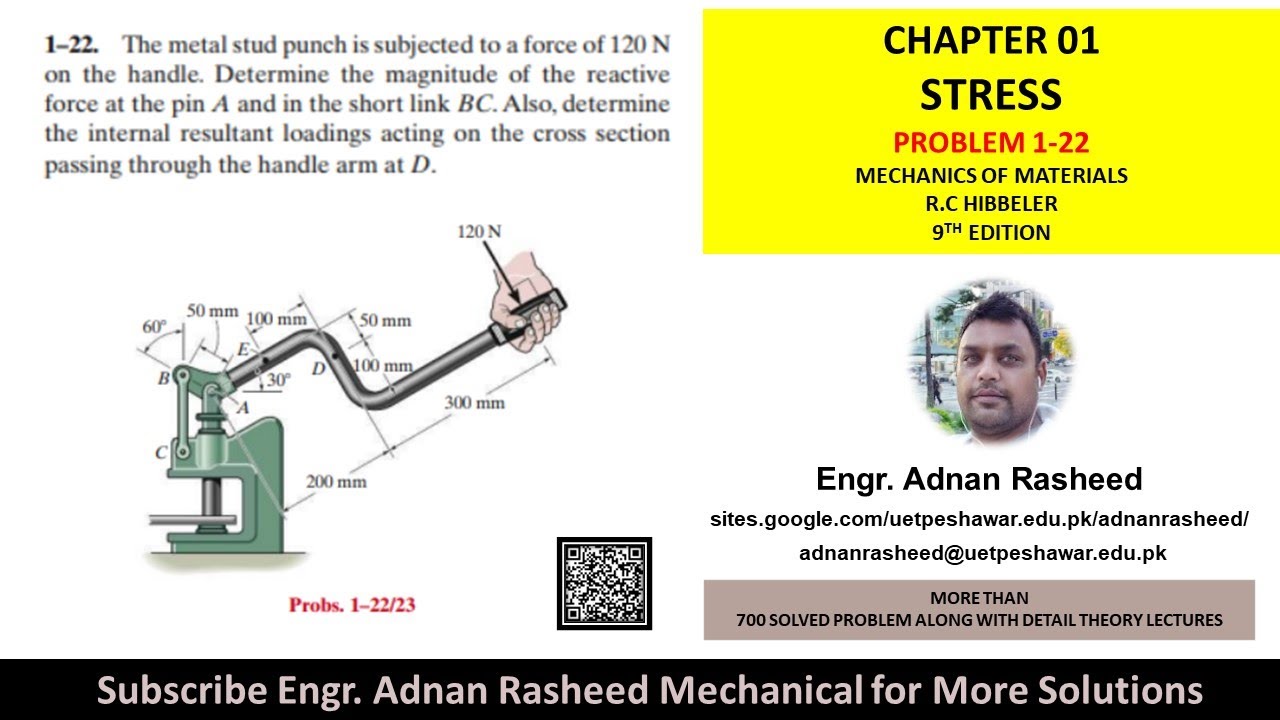

Determine internal resultant loading | 1-22 | stress | shear force | Mechanics of materials rc hibb

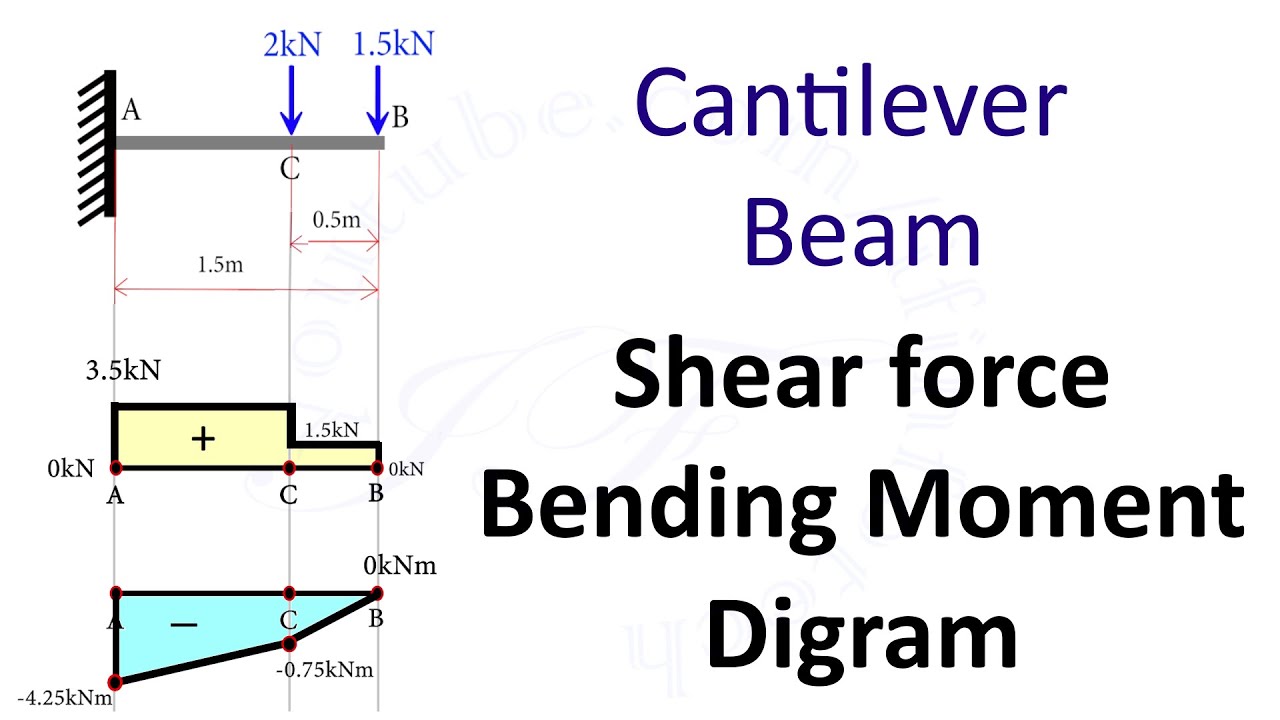

Video #4 Balok Kantilever

Cantilever Beam: Shear Force and Bending Moment Diagram [SFD BMD Problem 2] By Shubham Kola

Resultant internal loadings acting on cross section | 1-23 | Stress | Mechanics of materials rc hibb

What is Digital Literacy & It's Importance #DigitalLiteracy

5.0 / 5 (0 votes)