Involute Gears Explained

Summary

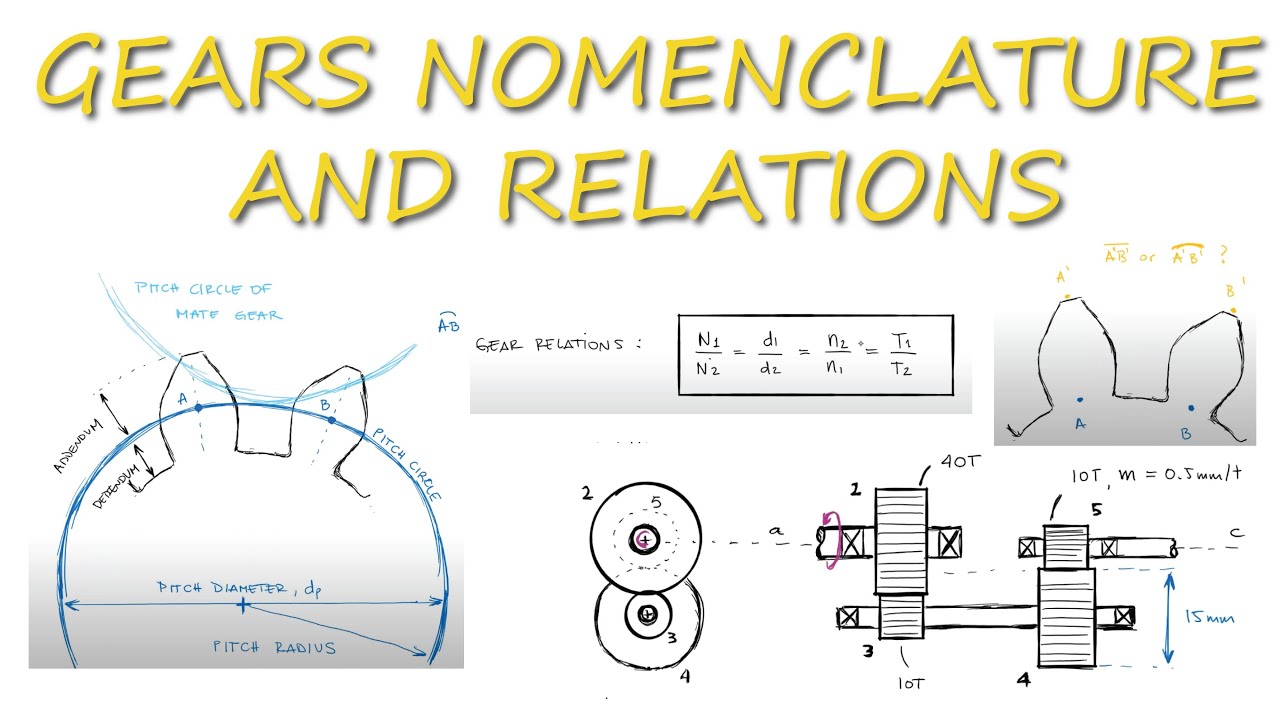

TLDRThis video delves into the fascinating world of involute gears, explaining how their smooth, efficient operation is achieved through curved tooth profiles. The involute curve, which defines the gear's teeth, ensures a constant transmission ratio while allowing gears of different sizes to mesh seamlessly, as long as they share the same module and pitch angle. The video explores the principles behind gear motion, including the line of action, pressure angles, and the relationship between gear sizes, and emphasizes how modular systems make gears universally compatible. The result is an engaging explanation of the mechanics that make gears function so smoothly in engineering.

Takeaways

- 😀 Gears are a fundamental symbol of engineering, but real gears have curved edges for smooth operation.

- 😀 The tooth profile of a gear follows the involute curve, which ensures that teeth slide smoothly over each other.

- 😀 The involute curve is defined by the unwinding of a string from a circle, and it is fundamental to gear function.

- 😀 When gears mesh, the involute curves of their base circles touch and slide over each other, creating ideal gearing.

- 😀 Involute gears are always perpendicular to the string, which allows them to slide freely at any contact point.

- 😀 The distance between gear axes can change without altering the involute curve, maintaining the same angular velocity ratio.

- 😀 A gear's base circle defines the starting radius for the involute curve, which determines the shape of the gear teeth.

- 😀 The contact point between gears lies on the line of action, which is tangent to the base circles and determines the pressure angle.

- 😀 The pitch of a gear defines the repeating pattern of its teeth and is related to the module, which standardizes gear sizes.

- 😀 Gears are modular, meaning any gear can mesh with another gear as long as they share the same module and pitch angle.

Q & A

What is the main focus of this video?

-The main focus of the video is to explain the functioning and design of gears, specifically how involute gears work and why they are efficient in mechanical systems.

How does the shape of a real gear differ from the common image of a gear?

-Unlike the common perception of gears with sharp edges, real gears have curved edges. This allows them to mesh smoothly without grinding.

What is the involute curve, and why is it important in gear design?

-The involute curve is a specific type of curve that is generated by unwinding a string from a circle. It is essential in gear design because it ensures that gears mesh smoothly, maintaining a constant transmission ratio.

How is the involute curve mathematically defined?

-The involute curve is defined by an x and y component of a function, which depends on the input angle (phi). It is drawn in two parts: a circle with a radius 'r' and a tangent vector whose length is the arc length of the base circle corresponding to the angle.

What happens when two involute curves are connected?

-When two involute curves are connected, they function similarly to a belt drive, with their rotation ratios being constant and proportional to the radii of the circles. This results in ideal gearing.

What is the significance of the perpendicular relationship between involutes and the string?

-The fact that the involutes are always perpendicular to the string ensures that the gears slide over each other smoothly, maintaining a constant motion without interference.

How does the axial distance between gears affect their motion?

-The axial distance between gears does not affect their motion or the involute curve itself. The point of contact changes, but the angular velocity ratio remains the same.

What role does the base circle play in gear design?

-The base circle defines the starting radii of the involute curves, which are crucial for determining the shape of the gear teeth.

What is the pressure angle, and how does it relate to gears?

-The pressure angle is the angle formed between the tangent at the pitch circle and the line of action. It is an important factor in determining the efficiency and smoothness of gear meshing.

What is the module, and why is it important in gear compatibility?

-The module is a value that defines the size of the teeth on a gear. It is calculated by dividing the pitch by pi. Gears with the same module and pressure angle are compatible and can mesh properly, regardless of their size.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآن5.0 / 5 (0 votes)