Welding Basics for Beginners

Summary

TLDRIn this video, Steve Christena from Arc Academy introduces welding to beginners, explaining the basics of MIG, Stick, and TIG welding. He covers the common elements of welding, such as heat source, filler metal, and shielding gas. Each welding process is broken down, highlighting the advantages and challenges. MIG is ideal for beginners and indoor use, Stick works well outdoors and on thicker metals, while TIG is suited for high-quality, detailed welds on thin metals. The video also guides viewers on selecting the right welder based on their specific needs and applications.

Takeaways

- 😀 Arc Academy is a beginner-focused welding school in Chicago, Illinois, teaching foundational welding skills.

- 😀 Welding involves liquefying a base metal with heat, which fuses together through processes like MIG, Stick, and TIG welding.

- 😀 MIG welding uses a wire electrode and shielding gas, making it easier to learn, cleaner, and suitable for a variety of metal thicknesses.

- 😀 Stick welding, a flux-based process, is ideal for outdoor work, welding thicker metals, and for working with dirty or rusted surfaces.

- 😀 Stick welding has some downsides, including spatter, fumes, and less aesthetic welds, which makes it less ideal for indoor use.

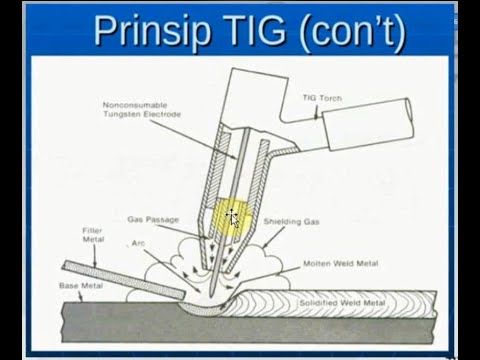

- 😀 TIG welding offers the highest-quality, most aesthetically pleasing welds, and is great for thin metals, but it's challenging to master and slower.

- 😀 TIG welding requires controlling all three elements of the process: heat, filler metal, and the tungsten electrode, which can be tricky.

- 😀 When choosing a welding method, consider the type of work: Stick is best for outdoor, dirty, or thicker materials; TIG is great for thin, precise work; and MIG is ideal for indoor, versatile applications.

- 😀 MIG welding is suitable for steel, stainless steel, and aluminum, while Stick welding is ideal for steel, stainless steel, and cast iron.

- 😀 TIG welding is versatile and can weld a wide range of metals, including steel, stainless steel, aluminum, copper, brass, chromoly, and exotic metals like magnesium and titanium.

Q & A

What is the main purpose of Arc Academy?

-Arc Academy is a beginner and entry-level welding school in Chicago, Illinois, that teaches people how to weld, specifically focusing on beginners who may not have any prior knowledge of welding.

What are the three most common welding processes mentioned in the video?

-The three most common welding processes mentioned are MIG welding, stick welding, and TIG welding.

What are the three basic elements of welding?

-The three basic elements of welding are the heat source, the filler metal, and the shielding gas or flux.

What makes MIG welding easier to learn compared to other welding methods?

-MIG welding is easier to learn because it involves preset parameters, resulting in a cleaner process without slag, and it can work with a variety of metal thicknesses.

Why is stick welding ideal for outdoor use?

-Stick welding is ideal for outdoor use because it is a flux-based process, making it less affected by wind, and it can work well with thicker metals and dirty materials.

What are the main disadvantages of stick welding?

-The main disadvantages of stick welding are the high levels of spatter, vapor off-gassing, and fumes, making it less suitable for indoor work.

What is a key advantage of TIG welding?

-A key advantage of TIG welding is that it produces the highest quality and most aesthetically pleasing welds, especially on thinner metals.

Why is TIG welding considered more difficult to control compared to MIG and stick welding?

-TIG welding is more difficult to control because it requires the welder to manage three elements: heat, filler metal deposition rate, and the non-consumable tungsten electrode, all at once.

For what types of projects is TIG welding best suited?

-TIG welding is best suited for projects requiring high-quality, aesthetically pleasing welds, such as automotive sheet metal, motorcycle frames, and thin metal materials.

How do you decide which welding process to use?

-The choice of welding process depends on the materials you are working with and the type of project. For outdoor, dirty, or thick metal welding, stick welding is best. For thin metals or high-precision work, TIG welding is ideal. MIG welding is a good choice for general indoor work with a wide range of metal thicknesses.

What types of metals can be welded using MIG, stick, and TIG welding processes?

-MIG welding is typically used for steel, stainless steel, and aluminum alloys. Stick welding works on steel, stainless steel, and cast iron. TIG welding is versatile and can weld any metals that conduct electricity, including steel, stainless steel, aluminum, copper, brass, chromoly, and exotic metals like magnesium and titanium.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

DASAR-DASAR & PENGERTIAN SEMUA JENIS TIPE PENGELASAN UNTUK PEMULA

Stick Welding Basics: Full Tutorial

Materiais e Processos de Fabricação para Engenharia de Produção - Princípios de soldagem

STICK WELDING 101: Getting Started With SMAW

4 Types of Welding Explained: MIG vs TIG vs Stick vs Flux Core

Prinsip Kerja dan Komponen Las TIG (Tungsten Inert Gas)

5.0 / 5 (0 votes)