TUTORIAL CARA VAKUM AC

Summary

TLDRThis tutorial explains the essential process of vacuuming an AC system to remove trapped air and moisture, ensuring the unit operates efficiently and prolongs its lifespan. The video covers the necessary tools, including a manifold gauge and a vacuum pump, and provides step-by-step instructions on connecting equipment, monitoring the vacuum process for at least 15 minutes, and checking for leaks. It emphasizes the importance of a thorough vacuuming process for both new and second-hand AC units, highlighting the risks of not removing air and moisture, such as compressor failure.

Takeaways

- 😀 The vacuuming process is essential for removing trapped air in the pipes of an AC unit to ensure efficient performance.

- 😀 Vacuuming prevents the formation of moisture in the AC system, which can damage compressor oil and reduce the compressor's lifespan.

- 😀 The air trapped in the pipes can turn into water vapor, which when combined with compressor oil, forms a gel-like substance that harms the compressor.

- 😀 It's crucial to vacuum both new and second-hand AC units, regardless of pipe length, to maintain optimal performance.

- 😀 Using a vacuum pump removes not only air but also dirt, debris, and moisture from the AC pipes, ensuring the system is clean and dry.

- 😀 The vacuuming process should last a minimum of 15 minutes, as specified by manufacturers, to ensure thorough removal of contaminants.

- 😀 If a technician vacuums for only a few minutes, it's advisable to request a longer duration to ensure proper vacuuming.

- 😀 After vacuuming, checking for leaks is important. If the vacuum gauge needle moves upwards after shutting off the pump, it indicates a leak in the system.

- 😀 The vacuum pump should be connected to the AC system carefully, ensuring all connections are tight before starting the process.

- 😀 Proper safety gear, such as rubber sandals or boots, should be worn during the vacuuming process to ensure safety while handling equipment.

Q & A

What is the purpose of the vacuuming process in AC installation?

-The vacuuming process is used to remove trapped air, moisture, and debris from the pipes in an air conditioning system. This ensures that the system is clean and dry, which prevents damage to the compressor and extends the lifespan of the AC.

Why is it important to remove air from the pipes in an AC system?

-Air trapped in the pipes can cause moisture to form. This moisture can mix with the compressor oil and turn it into a gel-like substance, which reduces its ability to lubricate the compressor, leading to wear and premature failure of the compressor.

How long should the vacuuming process be done?

-The vacuuming process should last at least 15 minutes, as recommended by the manufacturer, to ensure that all air, moisture, and debris are completely removed from the pipes.

What tools are needed for vacuuming an AC system?

-The tools required for vacuuming an AC system include a manifold gauge, a vacuum pump specifically designed for AC systems, and vacuum hoses (blue, red, and yellow hoses).

Can the vacuuming process be skipped if the pipes are short?

-No, the vacuuming process should never be skipped, regardless of the pipe length. Even for short pipes, it is necessary to remove any air and moisture to ensure the system operates correctly.

What happens if the vacuuming process is done for less than 15 minutes?

-If the vacuuming process is done for less than 15 minutes, it might not fully remove all air, moisture, and debris, which can lead to damage to the compressor, a reduction in efficiency, and a shorter lifespan of the AC system.

How can you check for leaks after the vacuuming process?

-To check for leaks, monitor the pressure gauge after the vacuuming process. If the needle moves up, it indicates that there is a leak in the system, and the leak should be located and fixed before continuing.

What should you do if the vacuum pump stops working after the process has been completed?

-If the vacuum pump stops working, ensure that it is properly connected to a power source. If the pump has malfunctioned, it may need to be repaired or replaced before continuing with the process.

What is the role of synthetic oil in modern AC systems?

-Modern AC systems use synthetic oil, which is crucial for lubricating the compressor. If this oil becomes contaminated with moisture, it can become jelly-like, reducing its lubricating properties and damaging the compressor.

Why is it essential to check for leaks after installing an AC system?

-It is essential to check for leaks after installation because even small leaks can lead to a loss of refrigerant, compromising the AC system's cooling efficiency and potentially causing further damage.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

AC 5. Pengisian Freon, Pengosongan, Pevakuman, Pengisian Oli Kompressor AC | Refrigrant Conditioning

Tutorial isi freon AC untuk pengguna AC

Understanding How HEPA Filters and Air Conditioning System Provide Clean & Safe Air in an Aircraft!

Video Pembelajaran Mengoperasikan Vacuum Pump

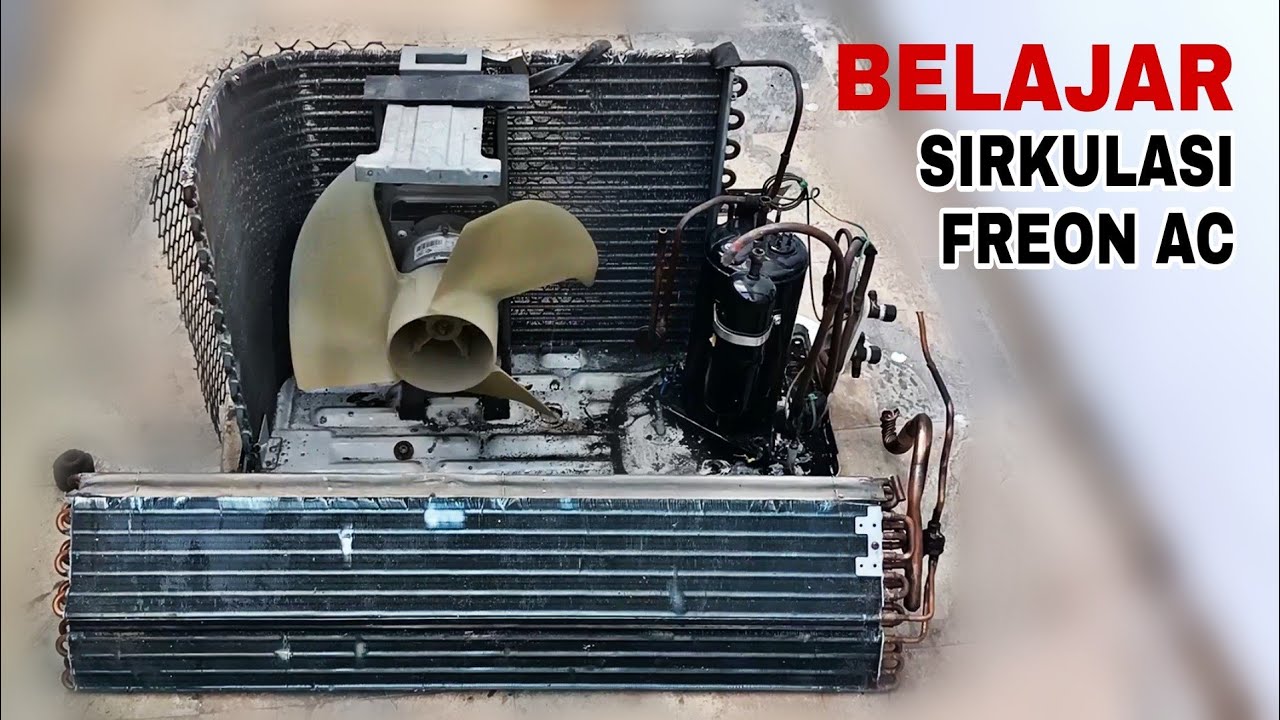

Belajar sirkulasi freon AC untuk pemula agar bisa servis atau perbaiki AC

How to Remove (Recover) Refrigerant From a Running AC System

5.0 / 5 (0 votes)