Phenol from Salicylic Acid

Summary

TLDRIn this video, the process of synthesizing phenol from salicylic acid through thermal decarboxylation is explored. The host demonstrates the setup, explains potential side reactions, and discusses the challenges of achieving a high yield. After setting up a distillation apparatus and carefully controlling temperatures, the phenol is distilled, purified, and isolated. The process also reveals a variety of byproducts, including phenyl salicylate, and the video covers troubleshooting during the experiment. Ultimately, the goal is to produce pure phenol for future use in various applications, showcasing the complexities of lab-scale organic chemistry.

Takeaways

- 😀 The video demonstrates the synthesis of phenol from salicylic acid via thermal decarboxylation, where CO2 is removed from the carboxyl group using heat.

- 😀 Thermal decarboxylation occurs at high temperatures (around 180°C) to break the bond between the carboxyl group and the aromatic ring of salicylic acid.

- 😀 One major side reaction is the formation of phenyl salicylate (an ester) between the hydroxyl group of salicylic acid and its carboxyl group.

- 😀 Other possible side reactions include the formation of salicylic acid dimers or dienyl ethers due to high heat and the presence of water.

- 😀 A significant side effect of this process is the sublimation of salicylic acid, which can cause impurities to be distilled along with the phenol.

- 😀 The goal of this experiment is to obtain phenol, a compound that is less commonly found in consumer products, unlike salicylic acid, which is widely used in skincare and acne products.

- 😀 A short-path distillation system is used to prevent the phenol from solidifying in the condenser due to its relatively high melting point at room temperature.

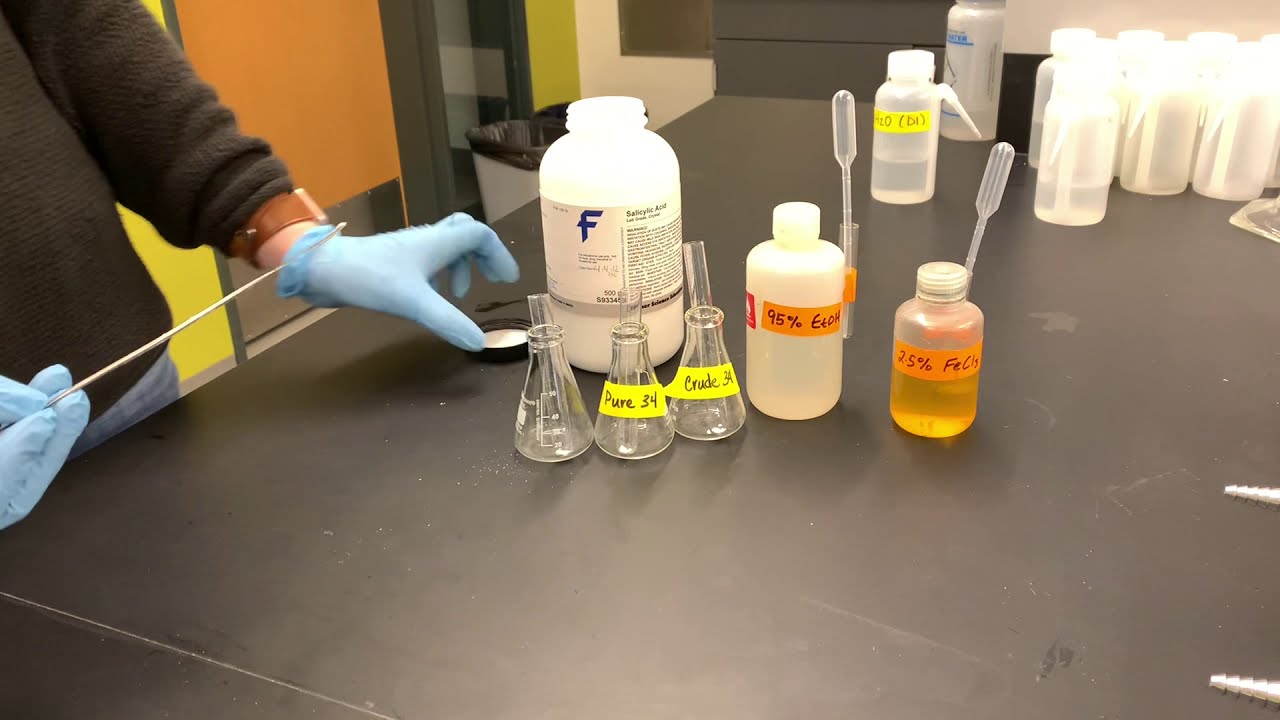

- 😀 The apparatus setup includes a heating mantle, round-bottom flask, short-path distillation head, and a receiving flask for collecting phenol.

- 😀 The process involves careful temperature control to ensure the correct balance between phenol collection and the minimization of salicylic acid distillation.

- 😀 The final product is crude phenol, which is distilled again to purify it, resulting in a yield of 53g of relatively pure phenol, despite some challenges in temperature control during the reaction.

Q & A

What is the primary compound being synthesized in this video?

-The primary compound being synthesized is phenol, which is derived from salicylic acid through thermal decarboxylation.

How is phenol produced from salicylic acid in this experiment?

-Phenol is produced through a process called thermal decarboxylation, where carbon dioxide is removed from the carboxyl group of salicylic acid by heating it.

What are some side reactions that may occur during this synthesis?

-Side reactions include the formation of phenyl salicylate (an ester), salicylic acid reacting with itself to form salosalicylate, and the formation of dienol ether.

What is the industrial relevance of phenol in this process?

-Phenol is produced in large quantities in industry, and while it is not commonly found in consumer products, its precursor, salicylic acid, is widely used in acne and skincare products.

What are the challenges of isolating phenol directly from consumer products?

-Phenol is not commonly found in consumer products, and even when it is present, like in throat sprays, it is in very small concentrations and difficult to isolate.

What are the components of the apparatus used for the reaction?

-The apparatus includes a 1L heating mantle, a 500mL round-bottom flask, a short-path condenser, and a thermocouple thermometer to measure the reaction temperature.

Why is the short-path distillation apparatus used in this reaction?

-The short-path distillation apparatus is used because it provides a shorter path for the distilled gases, preventing phenol from solidifying in the condenser, which is critical since phenol is a solid at room temperature.

What was the role of carbon dioxide during the reaction?

-Carbon dioxide is produced during the decarboxylation process and helps push the phenol vapors through the apparatus for collection.

What temperature is ideal for the reaction and why?

-An ideal temperature for the reaction is around 165°C at the still head. This balance helps collect phenol efficiently while minimizing the sublimation of salicylic acid.

What issue occurred with the temperature during the experiment, and how was it addressed?

-The temperature was initially too high, which caused some salicylic acid to sublimate and clog the condenser. The issue was resolved by lowering the temperature and using a heat gun to clear the condenser.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآن5.0 / 5 (0 votes)