Splitting the Tractor and More Surprises | Farmall 856 Restoration Episode 4

Summary

TLDRIn this home tractor restoration video, the narrator splits his Farmall 856 to inspect seals and determine if they are leaking. He discovers the engine rear main seal and transmission seals need replacing. While disassembling components, he finds damage to the clutch torque amplifier shaft, likely from a prior pilot bearing failure. He debates whether to fully split the transmission to replace the costly torque amplifier, seeking viewer input. Though not urgent, he leans toward doing a complete overhaul for long-term reliability rather than a quick fix.

Takeaways

- 😀 Pete is restoring an IH 856 tractor and splitting it to inspect seals

- 😊 Pieces fell out of the final drive case previously - likely from a broken detent spring

- 👷♂️ Pete is disconnecting parts like the pilot valve to prep for splitting the tractor

- 🔧 He uses splitting stands to separate the tractor and inspect the seals

- 🚜 The engine rear main seal and transmission seals are leaking and need replacing

- ⚙️ The clutch can be replaced while split - Pete will also have the flywheel machined

- 🔎 The clutch shafts show wear - the inner one is damaged and may need a new torque amplifier

- 💭 Replacing the torque amplifier would allow fixing it right but is a lot of extra work

- 😕 The clutch isn't worn out but since the tractor is split already it makes sense to replace it

- 🤔 Pete is unsure whether to replace just the clutch or go further and do the torque amplifier

Q & A

What fell out of the final drive case when the oil was drained?

-Some broken pieces fell out, including a spring and a roller that rolls around on the detent plate. It was determined they likely came from the broken spring in the range transmission cover.

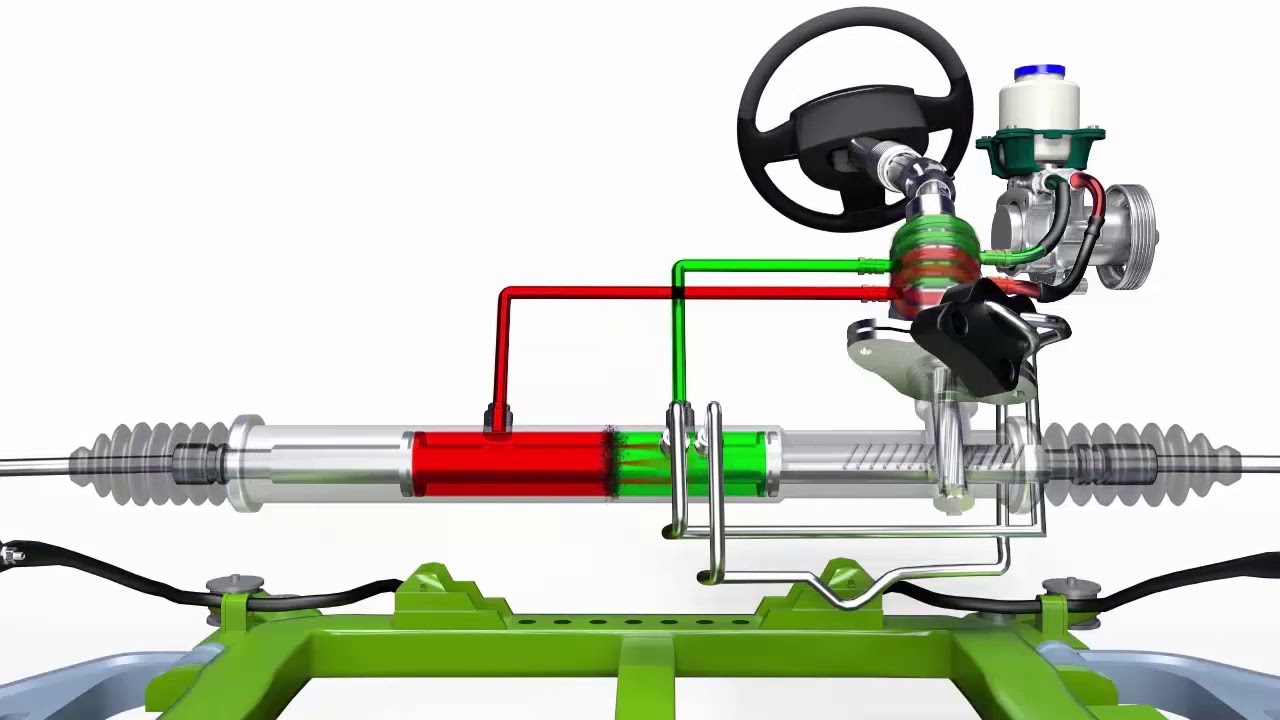

What is the pilot valve for?

-The pilot valve is part of the power steering hydraulic system. It provides hydraulic fluid to the power steering system when the steering wheel is turned.

How does the pilot valve work?

-It has a spool valve inside that is nudged off-center when the steering wheel is turned, allowing pressurized fluid from the MCV to flow to the power steering cylinder to provide power steering.

What needs to be done to split the tractor?

-Steps include disconnecting the power steering lines, removing some bolts from the clutch housing, putting the tractor on stands, and inserting dowel pins to keep the shaft plates aligned.

What was found when inspecting the split tractor?

-The rear main seal and possibly the gasket were found to be leaking. The engine main seal also showed signs of leaking.

What shaft was found to be worn?

-The live shaft splines that turn all the time were worn about a third of the way through.

What damage was found on the clutched shaft?

-The end of the clutched shaft was damaged in the past when a pilot bearing went bad. It had been dimpled with a punch to try to fix it.

What does the video creator debate doing?

-He debates whether to split the midsection further to replace the torque amplifier due to the damaged clutched shaft.

What would replacing the torque amplifier involve?

-It would require splitting the midsection off, pulling out the transmission guts, removing the MCV, and installing a new torque amplifier.

Why might it be advisable to replace the torque amplifier?

-Since the tractor is already disassembled, it may be worth the effort to replace it and ensure smooth shifting long-term.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

5.0 / 5 (0 votes)