CORGHI PRO750-2D Presentation & Balancing Procedure

Summary

TLDRThis video introduces the Corgi Proline 750 2D balancer, showcasing its features and accessories, including the hood, LED illuminator, and laser line. The machine handles wheels up to 35 inches in diameter and 20 inches in width, supporting up to 154 pounds. It demonstrates both dynamic and static balancing, highlighting the process of measuring wheel dimensions, applying clip-on and adhesive weights, and using advanced alloy balancing modes. The optional laser line and illuminator help with precise weight placement, ensuring accurate balancing for both steel and alloy wheels.

Takeaways

- 😀 The Corgi Proline 750 2D Balancer comes with several key features including a hood, LED illuminator, laser line, and multiple accessories like a weight hammer and cones.

- 😀 The machine can accommodate rim diameters up to 35 inches and tires up to 44 inches in diameter and 20 inches in width, handling assemblies up to 154 pounds.

- 😀 The dynamic balancing process involves using the internal data gauge to measure the wheel's distance and diameter, after which you input the wheel width to proceed with the balancing process.

- 😀 The machine automatically calculates required dimensions and guides the user to apply clip-on weights at specified locations, such as the top of the wheel (hour 12).

- 😀 A static balance mode is available, focusing on controlling the vertical bounce of the wheel, with measurements of wheel width and other dimensions taken automatically by the machine.

- 😀 In static balance mode, users apply adhesive weights to the wheel's middle to avoid amplifying any dynamic imbalance during the balancing process.

- 😀 The Proline 750 2D has two precision alloy balancing modes: clip-on stick-on and stick-on stick-on, each designed to precisely balance alloy wheels with varying configurations.

- 😀 In clip-on stick-on mode, the machine helps position weights on both sides of the wheel, with the optional LED laser line assisting in aligning the weights at precise locations.

- 😀 The stick-on stick-on mode involves measuring the wheel's dimensions and applying adhesive weights, with precise guidance provided for each placement to ensure accurate balancing.

- 😀 The machine also offers an option to hide weights behind spokes, recalculating the necessary values to maintain the balance while distributing the weights for a more aesthetic appearance.

Q & A

What is the Corgi Proline 750 2D Balancer?

-The Corgi Proline 750 2D Balancer is a machine designed for dynamic and static balancing of wheels, equipped with optional accessories such as a hood, LED illuminator, and laser line for precise balancing. It can handle a variety of wheel sizes and types, including up to 35-inch diameter rims and 44-inch diameter tires.

What are the standard accessories included with the Corgi Proline 750 2D Balancer?

-The standard accessories include a weight hammer, four cones to accommodate 42 to 156 mm diameter bore openings, a speed nut, a pressure cup, and a rubber protector.

What is the maximum weight the Corgi Proline 750 2D can handle?

-The machine can handle wheel assemblies weighing up to 154 pounds on its 40 mm shaft.

How does the machine acquire the wheel's distance and diameter for dynamic balancing?

-The machine automatically acquires the wheel's distance and diameter by using an internal data gauge that touches the left side or inside of the wheel.

What is the purpose of measuring the wheel width (Dimension B)?

-Measuring the wheel width (Dimension B) is necessary to input the correct data for the balance calculation, ensuring accurate results when balancing the wheel.

What does the flashing LED indicator mean during dynamic balancing?

-The flashing LED indicator indicates where and how much weight to apply, guiding the user to correctly balance the wheel by applying the right amount of weight at specific positions (e.g., top dead center or bottom center).

How is static balancing different from dynamic balancing?

-Static balancing focuses on controlling the up-and-down bounce of the wheel, as opposed to dynamic balancing, which corrects both the side-to-side and up-and-down imbalances.

What is the significance of the optional LED illuminator and laser line in the balancing process?

-The LED illuminator and laser line assist in precise weight placement on the wheel by visually marking the exact location where weights should be applied, ensuring accurate balance.

What is the 'clip-on' and 'stick-on' weight balancing method?

-In the 'clip-on' method, weights are attached to the outer part of the wheel, while the 'stick-on' method uses adhesive weights placed on the inner part of the wheel, typically for alloy wheels. The machine can automatically switch between these methods based on the detected wheel configuration.

What does the machine mean when it prompts 'Go Aloo' during the balancing process?

-'Go Aloo' indicates that the machine has entered a highly precise alloy balancing mode, designed to ensure exact measurements and weight placement when balancing alloy wheels.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

Coats 1500 Wheel Balance Demo - Clip and Tape Weight --

All New 2026 KIA EV4 officially revealed! First Look!

HGIBO Gundam Zagan - UNBOXING & Review!

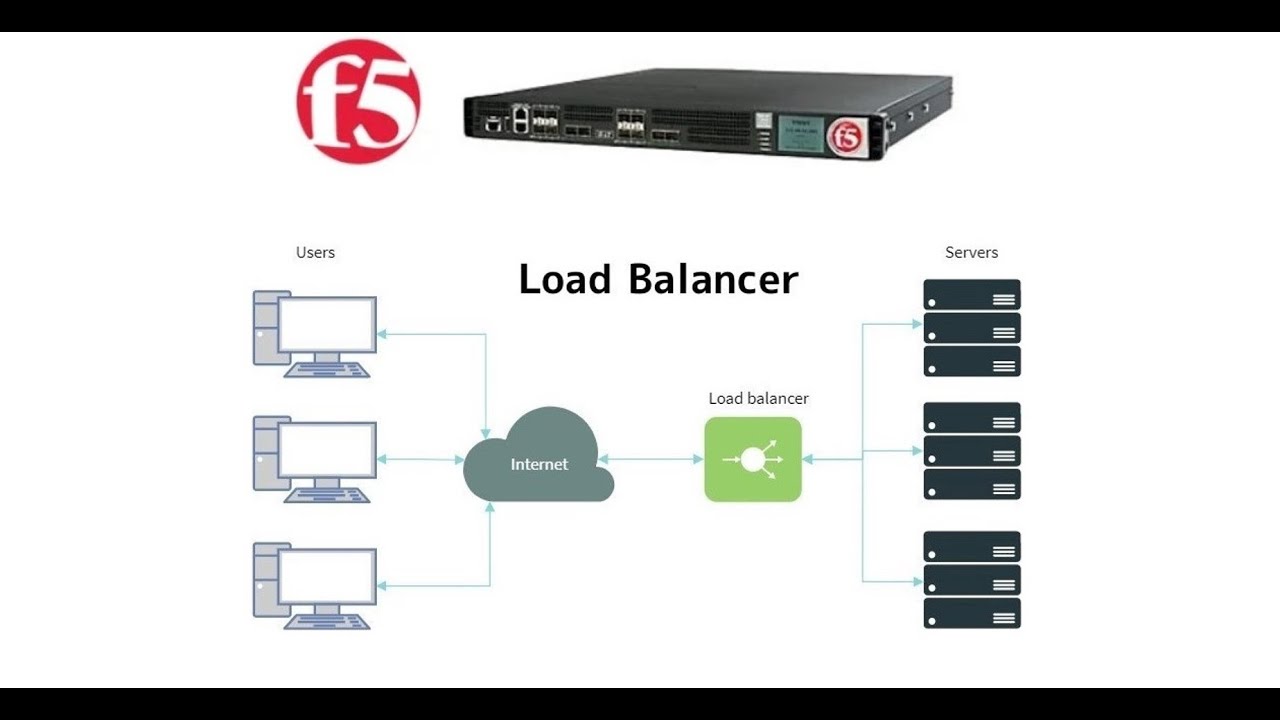

2. F5 Big IP LTM (Local Traffic Manager) || Load Balancer Explained

ULTRAMAN ZERO BEYOND 🔥 S.H.Figuarts Review 🔥 BAGUS TAPI...???

تجربتي مع انفنكس زيرو 40 INFINIX Zero | هل يعتبر مناسب او لا ؟

5.0 / 5 (0 votes)