BEGINI PROSES PEMBUATAN KABEL FIBER OPTIK INTERNET YANG KITA PAKAI

Summary

TLDRThis informative video explores the intricate process of manufacturing fiber optic cables, essential for modern internet connectivity. It details how light signals are transmitted through ultra-thin glass or plastic fibers, highlighting the steps from melting large glass tubes to forming fine strands. The video emphasizes the importance of fiber optics in delivering faster data transfer and greater bandwidth while being resistant to electromagnetic interference. With a focus on quality control and protective layering, the production process ensures durability and performance, showcasing the evolution from traditional copper cables to advanced fiber optic technology.

Takeaways

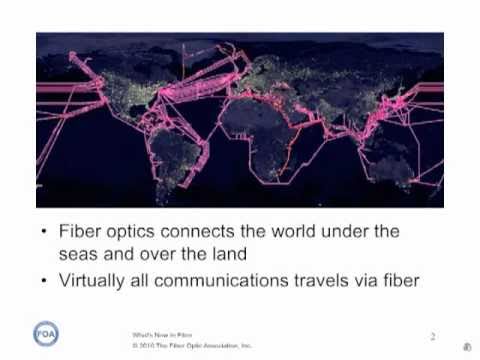

- 🌐 The internet is a crucial service in modern times, with fiber optic cables becoming increasingly important for data transmission.

- 🔌 Fiber optic cables are made of glass or plastic fibers thinner than a human hair, allowing for faster data transmission with high bandwidth capacity.

- ⚡ Fiber optic technology uses the principle of total internal reflection to transmit light signals over long distances.

- 🏭 The manufacturing process of fiber optic cables begins with large glass tubes that are heated and stretched into thin fibers.

- 🔬 Special machinery ensures that the fibers maintain a consistent diameter of approximately 120 micrometers during production.

- 🌈 Fiber optic strands are color-coded for identification and protection against contamination through a UV ink process.

- ✅ Before being used in cables, fiber optic strands undergo rigorous testing to ensure they meet industry specifications.

- 🛠️ The cable production process involves multiple stages, including coating, insulation, and jacketing to protect the fiber cores.

- 🐀 For outdoor applications, fiber optic cables often include additional protective layers to guard against rodents and environmental damage.

- 💡 Fiber optic cables are more efficient than traditional copper cables, carrying more data, requiring fewer repeaters, and being resistant to electromagnetic interference.

Q & A

What are optical fiber cables?

-Optical fiber cables are transmission channels made of glass or plastic fibers that are thinner than a human hair, used to transmit light signals for data transfer.

How do optical fiber cables work?

-They work on the principle of total internal reflection, where light signals are transmitted through the core of the fiber, allowing for faster data transmission and greater bandwidth.

What is the data transmission capacity of optical fiber cables?

-Optical fiber cables can transmit data at capacities up to 1.6 terabits per second.

What is the initial material used to create optical fibers?

-The initial material is a large glass tube, which is heated to over 2000 degrees Celsius to soften and stretch into thin fibers.

What quality control measures are taken during the production of optical fibers?

-The fibers are monitored for tension and diameter during the stretching process, and samples are tested under a microscope to ensure they meet industry specifications.

Why is color coding important in optical fiber production?

-Color coding helps identify different fibers within the cable and also provides a protective layer through the UV ink that is applied during production.

What materials are used for the outer jacket of optical fiber cables?

-The outer jacket is typically made from materials like medium-density polyethylene, PVC, or other fire-resistant plastics, chosen based on the cable's application.

What are the advantages of using optical fiber cables over traditional copper cables?

-Optical fiber cables are more efficient, capable of carrying more information over longer distances, are resistant to electromagnetic interference, and are difficult to tap without detection.

What steps are involved in the finalization of optical fiber cables?

-The finalization process includes wrapping the fibers with protective layers, testing for quality, and printing identification information before packaging.

How do optical fibers contribute to internet connectivity?

-Optical fibers enhance internet connectivity by providing high-speed data transmission capabilities, thus meeting the growing demand for bandwidth in modern communication networks.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآن5.0 / 5 (0 votes)